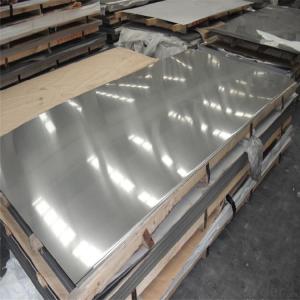

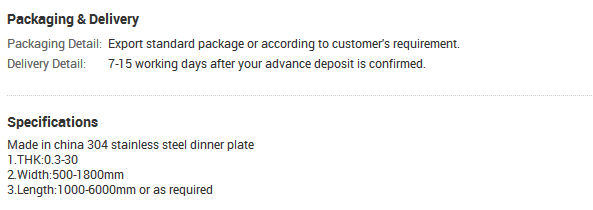

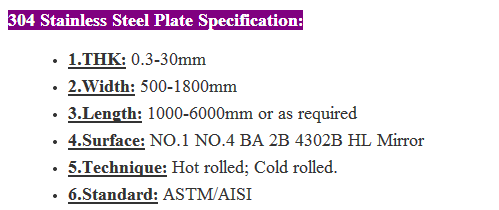

Made in china 304 stainless steel dinner plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can stainless steel pipes be used in power plants?

- Yes, stainless steel pipes can be used in power plants. Stainless steel is highly resistant to corrosion, making it suitable for various applications in power plants where there may be exposure to high temperatures, pressures, and corrosive environments. Stainless steel pipes are commonly used for transporting fluids such as water, steam, and chemicals in power plants. They are also used in various components such as heat exchangers, boilers, condensers, and turbines. The durability, strength, and resistance to corrosion of stainless steel make it a reliable choice for power plant applications.

- Q: What is the difference between double wall and single wall stainless steel pipes?

- The main difference between double wall and single wall stainless steel pipes lies in their structure and functionality. Single wall stainless steel pipes have a single layer of stainless steel, making them suitable for general applications where corrosion resistance is required. On the other hand, double wall stainless steel pipes consist of two concentric layers, with an air gap or insulation material between them. This design provides additional insulation, making double wall pipes more suitable for applications that require heat retention or insulation, such as high-temperature fluid transportation or exhaust systems.

- Q: What is the difference between Schedule 30 and Schedule 40 stainless steel pipes?

- Stainless steel pipes are classified into Schedule 30 and Schedule 40 based on their wall thickness and pressure ratings. The primary distinction lies in the wall thickness. Schedule 30 stainless steel pipes possess a slimmer wall in comparison to Schedule 40 pipes. Generally, the wall thickness of Schedule 30 pipes is less than that of Schedule 40 pipes. Consequently, Schedule 30 pipes exhibit a larger internal diameter than Schedule 40 pipes of the same nominal size. The pressure rating and strength of the pipes are directly influenced by the thickness of the pipe walls. Schedule 40 stainless steel pipes are engineered to withstand higher pressure and exhibit greater structural integrity as a result of their thicker walls. They find common usage in industrial settings or for plumbing systems in commercial buildings that involve the transportation of high-pressure fluids or gases. Conversely, Schedule 30 stainless steel pipes are typically employed in applications with lower pressure requirements. They are suitable for situations where more moderate pressure demands exist or where the transported fluid does not necessitate a higher pressure rating. To summarize, the primary disparity between Schedule 30 and Schedule 40 stainless steel pipes resides in their wall thickness. Schedule 40 pipes possess thicker walls and higher pressure ratings compared to Schedule 30 pipes. The choice between the two depends on the specific requirements of the application, including the pressure and nature of the transported fluid.

- Q: How do you prevent blockages in stainless steel pipes?

- To prevent blockages in stainless steel pipes, there are several measures you can take: 1. Regular cleaning: Clean the pipes on a regular basis to remove any accumulated debris or residue. This can be done using various cleaning methods such as mechanical cleaning tools or chemical cleaning solutions that are safe for stainless steel. 2. Proper disposal of waste: Ensure that you dispose of waste materials properly, avoiding dumping substances that can cause blockages, such as grease, oil, food scraps, or other solids. Use appropriate waste disposal systems or filters to trap these substances before they enter the pipes. 3. Avoid corrosive substances: Stainless steel pipes are resilient to corrosion, but exposure to certain highly corrosive substances can cause damage and blockages. Avoid using or disposing of chemicals or substances that are known to corrode stainless steel pipes. 4. Regular inspections: Conduct regular inspections of the pipes to identify any signs of blockages or potential issues. This can help in detecting problems early on and taking necessary preventive measures. 5. Proper installation: Ensure that the pipes are installed correctly, with proper alignment, support, and connections. This will help prevent the formation of blockages due to misaligned or poorly connected pipes. 6. Use strainers or filters: Install strainers or filters at the entry points of the pipes to catch any large particles or debris that can potentially block the pipes. Regularly clean or replace these strainers to maintain their effectiveness. 7. Avoid high-temperature buildup: Excessive heat can cause substances to solidify or congeal, leading to blockages. Avoid allowing substances to cool and solidify in the pipes by maintaining a suitable temperature and preventing sudden temperature changes. 8. Regular maintenance: Implement a regular maintenance schedule to keep the pipes in optimal condition. This can include activities such as flushing the pipes with hot water or using specialized cleaning solutions to remove any buildup or residue. By following these preventive measures, you can significantly reduce the chances of blockages in stainless steel pipes, ensuring their long-term functionality and minimizing the need for costly repairs or replacements.

- Q: Can stainless steel pipes be used for solar thermal systems?

- Indeed, solar thermal systems can utilize stainless steel pipes. Because of their ability to resist corrosion, endure high temperatures, and exhibit durability, stainless steel pipes are commonly opted for as piping in solar thermal systems. These systems harness the sun's heat to produce hot water or offer space heating, and stainless steel pipes are capable of withstanding the immense pressures and elevated temperatures inherent in such systems. Furthermore, the exceptional longevity of stainless steel pipes renders them a dependable choice for solar thermal applications.

- Q: What is the tensile strength of stainless steel pipes?

- The tensile strength of stainless steel pipes can vary depending on the specific grade and manufacturing process, but it typically ranges from 515 to 827 megapascals (MPa) or 74,800 to 119,900 pounds per square inch (psi).

- Q: What is the difference between seamless and seamless annealed stainless steel pipes?

- The manufacturing process and resulting properties of seamless and seamless annealed stainless steel pipes are the main points of differentiation between them. Seamless stainless steel pipes are created by piercing a hot billet or solid bar, forming a seamless hollow cylindrical shape. This manufacturing method eliminates the need for welding or any other joints, resulting in a continuous and uniform pipe without any seams. Seamless pipes are highly regarded for their exceptional strength and ability to withstand high pressures, making them a suitable choice for various industries such as oil and gas, petrochemical, and construction. On the contrary, seamless annealed stainless steel pipes undergo an additional heat treatment process known as annealing. Annealing involves heating the pipe to a specific temperature, maintaining it at that temperature for a certain duration, and then gradually cooling it. This heat treatment helps relieve internal stresses, decrease hardness, enhance ductility, and improve the overall mechanical properties of the stainless steel pipe. Moreover, the annealing process fosters the development of a more homogeneous microstructure, further improving the corrosion resistance of the stainless steel. This characteristic makes seamless annealed stainless steel pipes particularly appropriate for industries that require excellent resistance to corrosion, such as chemical processing, pharmaceuticals, and the food and beverage sectors. To sum up, although both seamless and seamless annealed stainless steel pipes are produced without any seams, the latter's additional annealing process enhances its mechanical properties and corrosion resistance, making it more suitable for specific industries and applications.

- Q: What is the working temperature range for stainless steel pipes?

- The working temperature range for stainless steel pipes typically ranges from -150°C (-238°F) to 816°C (1500°F).

- Q: 304L stainless steel pipe can withstand 0.1MPA?

- If you want to know how much pressure the steel pipe is under, you need to know the type of the stainless steel pipe.Pressure calculation formula of stainless steel management: pressure MPA=, tensile strength X40%X2X, wall thickness / outer diameterBut from my experience, generally speaking, stainless steel tubes can withstand 0. 1MPA. Unless it is used very thin stainless steel tube wall decoration.

- Q: What is the internal roughness of stainless steel pipes?

- The internal roughness of stainless steel pipes refers to the texture or unevenness on the inner surface of the pipes, which can affect the flow of fluids or gases through the pipes. It is typically measured in terms of roughness coefficients or Ra values, indicating the average height of irregularities on the pipe's interior.

Send your message to us

Made in china 304 stainless steel dinner plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords