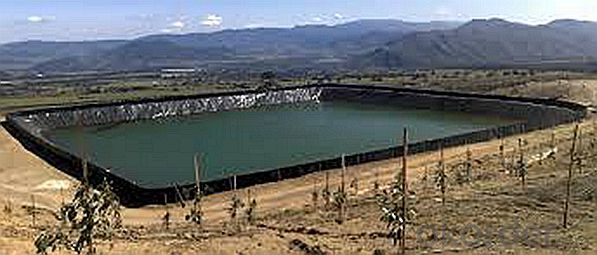

Geotextile Woven Filter Fabric Reinforced Linear Low-Density Polyethylene (LLDPE) Geomembranes for Floating Reservoirs and Seepage Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2. Product Feature

1) Good physical and mechanic performance

2) High tearing resistance, strong deformation adaptability

3) Puncture-resisting, aging resisting, ultra-violet radiation, oil and salt, and corrosion resistance

Application:

Dam,traffic tunnel,road,airport,drainage,

Thickness:

1mm-3mm

Length:

50-200m as customers' request

Width:

4m~9m

Standard:

ISO, CE

Feature:

Chemical Resistant

Surface:

Textured Surface

Product name:

hdpe geomembrane manufacturers

Keyword:

hdpe geomembrane manufacturers

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: A creek next to our property is eating away the embankment and an engineer suggested using the sand in the creek bed.. wrapping it up in geotextile fabric in the form of a burrito but he did mnot mention how to fasten them shut..any ideas or experience with erosion control out there?

- Get some tie wire or baling wire. It's a soft wire used for tying reinforcing steel together or for baling straw. You could also use plastic cable ties.

- Q: What are the different geotextile testing methods?

- There are several different geotextile testing methods, including but not limited to, grab tensile strength testing, puncture resistance testing, tear resistance testing, burst strength testing, and permeability testing. These methods help assess the physical properties and performance of geotextiles in various applications.

- Q: SNG400-3.5 geotextile is what model

- SNG400-3.5 refers to the national standard polyester staple acupuncture non-woven geotextile 400g / ㎡, width 3.5m. The index code for staple acupuncture nonwoven geotextiles is generally SNG / (1) (2) / (3) - (4) / (5). (1) that the use of raw materials fiber code: PET-polyester, PP-polypropylene, PA-nylon, PV-vinylon, PE-Ethylene (conventional polyester are generally vacant omitted code) (2) that polyester staple fiber non-woven Geotextile per unit area weight. (3) that the composite products in the polyester staple fiber non-woven geotextile weight per unit area, non-composite product vacancies. (4) width, expressed in meters (5) production department number: can express the product more specific characteristics, functions, varieties, sequences, etc., the general vacancy. For example, a 3.5m wide 400g / ㎡ polyester staple fiber nonwoven geotextile representation can be SNG / PET400-3.5, can also be expressed as SNG400-3.5

- Q: Can geotextiles be used in railway construction?

- Yes, geotextiles can be used in railway construction. Geotextiles are often utilized in railway projects for various purposes such as soil stabilization, erosion control, filtration, drainage, and separation. They help improve the durability and performance of railway infrastructure by providing reinforcement, preventing soil movement, and enhancing drainage systems.

- Q: Can geotextiles be used in green wall systems?

- Yes, geotextiles can be used in green wall systems. Geotextiles are often used as a filtration and separation layer between the soil and the retaining structure in green walls. They help retain moisture, prevent soil erosion, and provide stability to the system.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: What are the disadvantages of using geotextiles?

- There are several disadvantages of using geotextiles. Firstly, geotextiles can be quite expensive compared to other types of erosion control or soil stabilization methods. Additionally, they may require professional installation, which can add to the overall cost. Secondly, geotextiles are not a permanent solution and may degrade over time due to weather conditions and UV exposure. This can lead to the need for frequent replacements, resulting in additional expenses. Lastly, geotextiles may not be suitable for all soil types or project requirements, as they have limitations in terms of load-bearing capacity and effectiveness in certain applications.

- Q: What is the representative batch of geotextile?

- Geotextile batch is 2000 square meters.

- Q: Geotechnical deployment of aging detection of what indicators

- Material anti-aging performance testing, if the reality to consider, for too long, are generally used in the laboratory to accelerate the aging approach to consider. Aging the concept of aging is a big concept. Refers to the material in the external environment under the influence of time changes. Environmental effects are multifaceted, the role of light, the role of temperature, a chemical role, the role of micro-organisms and so on. Now generally referred to as aging, refers to the light aging. Light aging, refers to the material in a certain light exposure after a certain period of time after the performance of the material changes. The most commonly used indicator for photoaging is the strength retention of the material. That is, the ratio of the strength that remains after the light is retained.

- Q: How are geotextiles installed?

- Geotextiles are installed by first preparing the site by removing any debris and ensuring the surface is level. The geotextile fabric is then laid out over the designated area, with overlapping edges to ensure full coverage. It is secured in place using stakes or other appropriate methods. Care is taken to avoid any wrinkles or folds in the fabric, ensuring a smooth surface. Finally, the geotextile is covered with the desired material, such as soil or gravel, to provide additional support and protection.

Send your message to us

Geotextile Woven Filter Fabric Reinforced Linear Low-Density Polyethylene (LLDPE) Geomembranes for Floating Reservoirs and Seepage Control

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords