LDPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Metric Tons watt

- Supply Capability:

- 3000 Metric Tons per Month watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

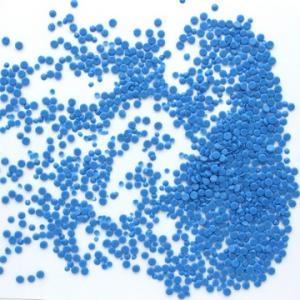

Appearance: White or Gray Granule

LDPE is the low density version of PE. This has less hardness, stiffness and strength compar

|

Product |

LDPE |

|

Resin Properities |

Test Result |

|

Melt Indexg/10min |

7~8 |

|

Densityg/ 12cm3' |

>0.922 |

|

Tensile-strength |

Mpa9 |

|

Elongationat break |

500% |

|

Softening pointVicat> |

83°C |

|

Physical Properties |

Test Method |

Nominal Value |

Unit | |

|

Density |

ISO 1183 |

0.921 |

g/cm3 | |

|

Melt Mass-Flow Rate (MFR) |

ISO 1133 |

1.9 |

g/10min | |

|

Hardness |

|

|

| |

|

Shore Hardness (shore D) |

ISO 868 |

45 |

| |

|

Mechanical Properties |

|

|

| |

|

Tensile Modulus |

ISO 527-2 |

175 |

MPa | |

|

Tensile Strength |

Yield, |

ISO 527-2 |

9.0 |

MPa |

|

Break, |

13.0 |

MPa | ||

|

Tensile Strain(Break) |

ISO 527-2 |

850 |

% | |

|

Modulus of Elasticity |

Internal Method |

250 |

MPa | |

|

Thermal |

|

|

| |

|

Vicat Softening Temperature |

ISO 306/A50 |

89.0 |

°C | |

|

Melting Temperature (DSC) |

DIN 53765 |

108 |

°C | |

|

Peak Crystallization Temperature (DSC) |

DIN 53765 |

97.0 |

°C | |

|

Heat of Fusion |

DIN 53765 |

110 |

J/g | |

|

Electrical |

|

|

| |

|

Volume Resistivity |

ASTM D257 |

8.5E+15 |

ohm •cm | |

|

Dielectric Strength |

ASTM D149 |

30.0 |

kV/mm | |

|

Dielectric Constant (60Hz) |

ASTM D150 |

2.20 |

% | |

|

Dissipation Factor (60 Hz) |

ASTM D150 |

0.00050 |

| |

- Q: Low pressure plastic raw materials in the process of blowing the two sides of the fold, how to deal with?

- The blowing ratio is one of the control points of blown film production and! Refers to the ratio between the bubble diameter and the diameter of not blowing blowing after.

- Q: How are plastic products made? What is the raw material of plastics?

- 1, simply say, use an injection molding machine to melt the material at high temperatures and then inject the mold into the mold at high pressure.2, raw materials are materials that have not been processed. Plastic raw material is standing (smaller than soybean).Generally ABS, PS, PP, and so on, these materials are not the same.3, melting at high temperatures, and stamping (I haven't seen)4, iron or steel mold, to see what your home appliance plastic parts, what kind of mold is it!

- Q: What material is good for plastic bellows?

- In the cases to recommend the use of PE (polyethylene) bellowsNo oxidizing acids, no environmental oils, vegetable oils, mineral oils, no organic solvents such as aliphatic hydrocarbons, aromatic hydrocarbons, ketones, esters, etc..Mainly used in the temperature range of -40 to 80 degrees Celsius environment; used in automobiles, motorcycles and other motor vehicle wire harness sheath; also used for household appliances, precision machine tools and other equipment wiring wire sheath.

- Q: What are the raw materials for making plastics?

- Plastic raw materials are extracted from some oil in the part of PC is most familiar with the material extracted from the oil, the PC material has a gasoline burning time; ABS is made from coal, ABS will show when soot like burn out; POM extraction from natural gas, POM will have a very smelly smell of gas when burned.

- Q: How do you increase the transparency and hardness of PP plastic suction pipes? What raw materials do you need to add?

- Add transparent nucleating agents to improve transparency, such as milk tea cups

- Q: What is the difference between PP raw material and modified PP?

- PP raw materials refer to resinsConcept: the word "plastic" in the word "plastic material" is intended as a material or plastic material that can be arbitrarily shaped into various shapes. In the dictionary is defined as "synthetic or natural polymers as the main component, under certain conditions can plasticization and molding can keep shape, the end product of materials.

- Q: What machines and materials are needed for the manufacture of disposable plastic cups?

- PP is crystalline polymer. PP is the most common plastic, and the density is only 0.91g/cm3 (smaller than water). In general plastics, PP has the best heat resistance, and its thermal deformation temperature is 80-100 DEG C and can be boiled in boiling water. PP has good stress cracking resistance and has a high bending fatigue life, commonly known as "fold gum"". PP products are light, tough and chemical resistant.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: What kind of plastic material is used for medical instruments?

- The resin used for medical plastic requires higher purity and narrower molecular weight distribution;

- Q: Application of CPE in plastics industry

- Resin type CPE in the product is also known as "A" material, elastic rubber type CPE has become B type material!Application: in the late 1990s, the domestic demand for high-performance flame-retardant rubber is increasing, especially the development of wire and cable industry and auto parts manufacturing industry, which has led to the consumption demand of rubber based CPE. Rubber based CPE is a kind of special synthetic rubber with good comprehensive properties, heat resistance, ozone aging and good flame retardancy.Mainly used in wire and cable (coal mine cable, UL and VDE standards such as the provisions of the wire), hydraulic hose, hose, adhesive tape, rubber sheet, PVC profiles, pipe modification, magnetic materials, ABS modification, and so on.

- Q: PVC what is the difference between raw and recycled raw materials?

- Products using recycled materials are brittle, easy to break or burst, very durable.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2009 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Mid East Northern Europe South Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

LDPE

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 Metric Tons watt

- Supply Capability:

- 3000 Metric Tons per Month watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords