KXT (F) Fly Ash (slag) Dosing and Control System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The KXT(F) achieve evenly and steadily dosing and accurately measurement for fly ash, and adapt for fly ash mass-flow measurement. The system is operating in 0.5-100t/h production line, receiving favourable reviews by users.

We can provide two form system base on different flow rate. For the flow rate of 0.5-30t/h system is consisted by flow-stability pre-feeder, flow meter and control system. For the flow rate of 15-150t/h system is consisted by special feeder valve, flow rate adjusting valve, weight adjusting valve and control system. The system is adapt for cement grinding station and cement milling system.

1. Composing of the KXT(F) system

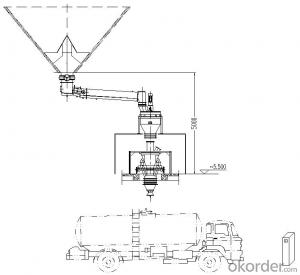

The KXT(F) system is composed by flow-stability pre-feeder, KL flow meter and control device. The flow-stabilizing pre-feeder is installed under the fly ash silo, which supply steady flow fly ash. The fly ash enter into KXT meter through flow-stabilizing pre-feeder, the control device base on the flow rate feed back to the flow-stabilizing pre-feeder to adjust the rotating speed.

2. Flow-stabilizing pre-feeder device

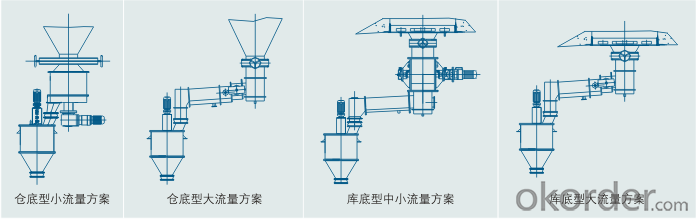

Flow-stabilizing pre-feeder device adopt different assembly mode base on the fly ash usage amount(t/h), storage and layout on-site. There are two basic programs to choose.

Program 1

Adopting WD flow-stabilizing pre-feeder as feeding device, with KL flow meter constitute a closed loop control. This program is usually used in small-flow fly ash measurement, measurement range is not more than 30t/h.

Program 2

The flow-stabilizing pre-feeder device made up of NXF rotary valve, pneumatic switch valve, electric flow valve and aerate separate case, with KL flow meter constitute a dosed loop control. This program is usually used in mass-flow fly ash measurement, measurement range is up to 150t/h.

3. Technical Index

Suitable material: fly ash, slag

Measuring accuracy: better than ±0.5%

Control accuracy: better than ±1.0%

Measuring range: 0.5~150t/h

environmental temperature: -20℃~60℃

relative humidity: ≤95%

Moisture of material: ≤ 2.5%

4. Specification | ||||||||

Model | KXT(F)-Ⅰ | KXT(F)-Ⅱ | KXT(F)-Ⅲ | KXT(F)-Ⅳ | KXT(F)-Ⅴ | KXT(F)-Ⅵ | KXT(F)-Ⅶ | |

Range (t/h) | 0.6~6 | 1.5~15 | 3~30 | 5~50 | 7~70 | 10~100 | 15~150 | |

Flow meter model | KL(F)-Ⅰ | KL(F)-Ⅱ | KL(F)-Ⅲ | KL(F)-Ⅳ | KL(F)-Ⅴ | KL(F)-Ⅵ | KL(F)-Ⅶ | |

Control cabinet | KXT-Ⅰ | KXT-Ⅱ | KXT-Ⅲ | KXT-Ⅳ | KXT-Ⅴ | KXT-Ⅵ | KXT-Ⅶ | |

The KXT (F) Coriolis force dosing system is applied to dosing fly ash and pulverized slag, it is benefit for the reuse of industrial waste and it can also increase mill output, ensure product quality and gain economic benefits. The system is characterized with stable feeding, accurate dosing, quick adjustment, simple process flow, compact arrangement, low investment cost, and wide measuring range etc.

The KL (F) system is designed under the patent, of which the principle is different from the glide slot and rush board flow meter, agravic meter, rotor scale, and belt weigher. The principle of the KL (M) meter is the Coriolis dynamical principle, the material moved in the dosing plate under the Coriolis force, and the force can be equal to the flow of the material, so the flow can be showed as special value. The KL (F) cannot be disturbed by any vibration and pressure, and the zero point can be changed by any deposit and aggradations.

The KL (F) flow meter can be used for the process of the dosing of the powder material independently. In the cement industry, the meter can be used for the feeding of the powder coal, fly ash, and several powder materials, like the grinding and mix of the clinker and the compound material, and the dosing of the bulk cement.

The flow meter is widely applied to the convoying and dosing of powder and granular materials in the metallurgy, electrical power, chemical engineering, foodstuff, ports, medicine power, , non-metallic mineral etc.

- Q: What are the potential defects of the automated material handling system?

- Automatic material handling system is to point to a series of related equipment and device, used in a process or a logical action system, coordination, reasonably to control the movement, storage, or material. Be able to carry out the material handling system and the design and arrangement of the container. Positioning of enterprise material handling system is a complicated problem, due to the imbalance between eastern and western regions in economic development in our country, determines the diversity of enterprise material handling system, both reflect the material handling in today's world of advanced science and technology level, by unmanned automatic handling car, automatic solid warehouse, automated conveyor etc of unmanned conveying system, there are still is in the middle of the last century the raw material handling conveyor line, but no matter what level, one thing is common, namely the material handling system and enterprise economic conditions, the level of product quality, Labour, match the market competitiveness of products and so on situation, that is to say, no one of the best material handling system,

- Q: What is a forklift? Forklifts are special equipment

- Hello, forklift truck is an industrial transport vehicle, which is a variety of wheeled transport vehicles for loading and unloading, stacking and short-range transportation. The forklift is a kind of special equipment management. Type: special motor vehicle in field (factory) Category: motor vehicle Varieties: forklift The operators must have the quality technical supervision bureau issued: Special equipment operator certificate Special motor vehicle operation in field (factory) Work item: forklift driver

- Q: The development of material handling

- The material handling equipment manufacturing industry provides various kinds of modern transportation equipment for the national economy, major construction projects and national defense security. Basic formed a comprehensive product range, good technical system and large enterprise groups, become an independent industry, machinery industry in the service of national economy in all walks of life, including for the second and the third industry provides a huge number, a great variety of products, can independently or with foreign cooperation for national key project to provide large lifting transportation machinery and complete sets of equipment system, and have a certain amount of exports. In 2011, there were 1,580 enterprises in the manufacturing industry of material handling equipment in China (RMB 20 million), and more than 400 000 employees. The industry realized sales revenue of 4723.47 billion yuan, with an industrial output value of 4712.23 billion yuan, with a total profit of 34.50 billion yuan, with an average annual compound growth rate of over 20%. With the expanding of the scale of production, improve degree of automation, material handling equipment manufacturing industry is more and more widely used in the process of modern production, function more and more big.

- Q: Why should we emphasize unitization and standardization in material handling

- Unitization is the application of scale thought to different materials. We can simplify the links, save the cost, and realize the overall optimization. To facilitate the mechanization of loading and unloading, reduce the labor intensity and improve the efficiency of the work. Reduce the damage caused by the transformation and improve the quality of logistics.

- Q: What is the material handling and handling equipment?

- . Highway transportation equipment Heavy tractor semi-trailer | van | | equipment | special transportation vehicle 9. Warehouse peripheral devices cllimbing trolley | slide machine loading and unloading platform | | | industrial door platform loading and unloading of rain loose 10. | | tray container unit equipment container bags | container net | slide 11. Forklift handling vehicle | electric flat car | | tractor attachments of ft | forklift parts 12. Manual handling equipment Hydraulic pallet truck cart hydraulic pallet stacker | | | lever type hydraulic lifting flat wagon | push car 13. Automatic sorting system, automatic sorting machine | | automatic sorting conveyor system automatic control systems and equipment

- Q: Urgent, please go to logistics expert, the question about the warehouse

- With the deepening of the reform and opening up, China's pharmaceutical industry also fast lane of development, the entire pharmaceutical industry production grew by an average of 17.7% a year, compared with the national industrial average annual growth rate of 4.4%, but also higher than in the developed countries in the world major drug. Over the past 30 years, the average growth rate has grown by 13.8 percent, making it one of the fastest growing medical markets in the world. According to the state economic and trade commission statistics, the pharmaceutical industry production, sales growth in 2002, gross industrial output value (constant) 21.95 billion yuan, an increase of 20.1%, down 0.9% growth than 1-2 month. The main business revenue was 196.100 million yuan, an increase of 12.8%, an increase of 2 percentage points from January to February. Ratios of 94.4%, year-on-year, and 1-2 month dropped 2.5 and 0.7% respectively, profit growth, the total profit of 990 million yuan, an increase of 12.8%, slower than 1-2 month fell 1%. According to the above data, the scale benefit of the pharmaceutical industry in China is emerging, the potential is big, the growth is good, the stable, healthy, rapid development stage. The graduation internship I came to yunnan double crane pharmaceutical company, personally experienced enterprise facing the opportunity and pressure, at the same time to realize enterprise logistics rationalization in the enterprise of great significance.

- Q: The function of material handling

- Material handling machinery factory factory factory logistics system in logistics system involving the coordination of production plan, process flow, handling operation, warehouse management, information system and so on various aspects. High quality and safe operation, lower logistics cost (including transportation, storage etc.). The main logistics system of the manufacturing process of the complex machine factory

- Q: Material handling system in the factory

- The machinery factory's internal logistics system involves the production plan, process flow, moving operation, warehouse management, information system and so on.

- Q: What is the relevant content of the flow of materials, storage and usage

- The transport system, the choice of carrying technology and equipment. To some extent determine the distribution and operation of the production logistics system. And the efficiency, complexity, size and economic effect of the production system are very strong. The important problem in production logistics is choosing the right transport equipment. These devices should be able to adapt to the nature, weight, shape, size and material flow of the moving material. We need to keep the fixed investment of the equipment low, and we need to meet the demand for moving. There are several kinds of moving, intermittent, and round-trip, which are divided into horizontal, oblique, vertical or two-dimensional direction. Other transport requirements include: channel flow shunt, location stop, high-speed moving, product placement, etc. Also consider moving objects and environments such as forming, powder, drying environment and cleaning environment. Finally, the mode of carrying, the combination of the equipment and the quantity of the specification are determined. The speed requirements of the transport are based on the production beat.

- Q: What are the requirements for the science of loading and unloading

- Reduce the load ratio of the mobile carrying equipment. To optimize the utilization rate of transportation equipment and manpower. Plan all the equipment to be maintained and maintained regularly. When there are more efficient means of handling and equipment, it should replace obsolete methods and equipment.

Send your message to us

KXT (F) Fly Ash (slag) Dosing and Control System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords