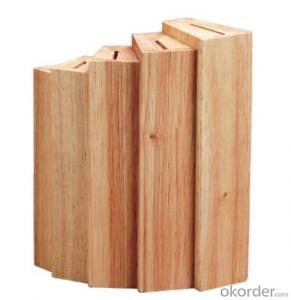

knife holder,F-KB040 acacia wood&optional inserted knife holder

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Key Specifications/Special Features:

Size can be customized

Can print your design of packing

Various styles for choice

Can print your design of packing

Small quantity order is accepted

We also have bamboo and plastic cutting board for choice

Our advantages:

All of our products are made by our experienced team of hard working artisans in a safe and responsible environment.

We take great pride not only in the outstanding quality of our products but also in the environment in which they are made

Every product that bears our name was made in an ethically and socially responsible way

Treated by high temperature, making our product antibacterial

Easy to clean, much durable and harder than other board due to the good material

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

- Q: The system is a wide number of 980TDb, lathe is the Yunnan machine tool factory. Whether it is a manual tool change or MDI way to enter the specified number of knives, the tool holder always turn around, until the emergence of PLC alarm 1000 change knife time is too long, A0000.0 knife can not reach the designated position. What the problem ah, I did not move the parameters of the machine, ah, this morning is good, work in the afternoon a boot on this.Back to the origin of the machine are abnormal, and can not return to the origin of the machine. Press the corresponding button after the machine does not respond, will not act. It's normal in the morning.

- The tool holder decoder is abnormal, the maintenance personnel should be required to adjust the hardware equipment, and then modify the solution

- Q: CNC lathe turret, sometimes why turn around.

- The general is a knife or bad coder and encoder connected to the data line broken, not to signal transmission system, data line control box is connected behind the knife and broken, suggest that you have the knife line reconnected or knife encoders change try, data line if is not the knife and the back of the control box is connected with a break

- Q: CNC lathe tool holder can not be reset after the knife to do?

- If it refers to the size of the knife after the processing is not allowed that it is possible to damage the screw rod, have to find a fitter check. General coupling may be broken. A bit more serious is that the nut is loose or the check of the screw rod is broken, even the screw rod is bent.

- Q: Why do you want to use the center frame and the tool holder when machining the slender shaft?

- In order to prevent the workpiece from bending deformation due to the radial cutting force, the central frame or the tool holder is used as the auxiliary support to increase the rigidity of the workpiece.

- Q: How to do the slide shoe

- Knife slide wire can only change the knife holder, if it is wearing a nail sliding wire, you can use the electric drill to wear the nail, remove the nail, replace it.

- Q: The difference between the center and the rest

- The 1 center frame is fixed on the bed rail, and has three independently movable supporting claws, and can be fixed by fastening screws. When in use, the workpiece is arranged on the front and rear top, in the first part of a workpiece support finishing smooth surface, then the proper position of center frame fastened to the guide rail, the final adjustment of three supporting claws, make contact with the workpiece supporting surface, and adjust to the proper degree of tightness.

- Q: These possibilities have been tested, or useless

- If the CNC bending machine, please check the machine parameters of the return voltage, and finally close to the voltage value, you can adjust it.

- Q: 1, CNC horizontal lathe tool holder with front and rear respectively. CNC vertical lathe tool holder how to classify?2, no matter front or rear CNC lathe, cutter movement from right to left (along the Z axis) with G42 compensation?

- In the tip of the compensation bar to enter the radius of the tip of the knife is good, of course, we must first know the radius of the tip of the nose,

- Q: How to return to the ordinary lathe tool

- Remove and check whether the spring pin back position is smooth (with the hands of the press about 20 times). Take a look at whether the end of the spring pin has been seriously worn, the same knife bottom surface is also turned over to see if the limit groove is also serious wear. Wear badly needed to repair or replace.

- Q: CNC lathe turret and turret turret that good

- In fact, the turret and turret turret, there is no good or bad, only the difference between the right.

Send your message to us

knife holder,F-KB040 acacia wood&optional inserted knife holder

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches