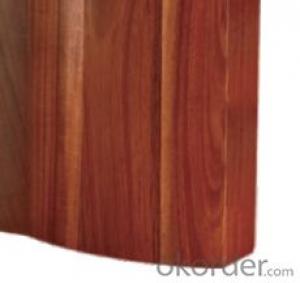

knife seat,F-KB015 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

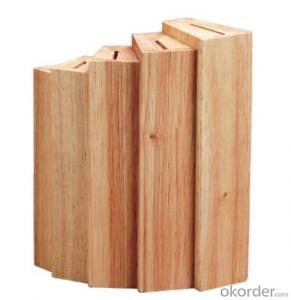

product name:acacia wood knife seat

material:acacia wood

N.W.:0.964kg

MEAS:25*15*6.5cm

Specifications:

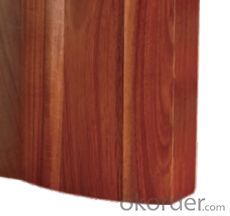

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

- Q: What are the reasons for the deviation of the CNC lathe tool holder after each turn

- One can not ignore it, not too much on the image processing, if it is the second case, the same is change the knife knife position error, the method of 1 open open turret encoder is damaged, replacement of damaged encoder.

- Q: How to install CNC machine tool

- You should first look at what products and processing process can be determined by what what tool, with a few knives, then you can choose to install the tool; we should consider the tool do not interfere in the process, should pay attention to the length of cutting machining depth and the selected is appropriate, but also note is the tip and selection tool the height of the knife is to be consistent, high attention to; such as your machine tool clamping position width is 64.0mm, then you must choose the cutter bar is 32.0mm, or the center of your nose is not high, so the processing will have a lot of problems; or you can according to the side making auxiliary tool carrier the installation is generally use screws; the cutter bar top dead on it

- Q: Why is the number 980 CNC lathe turret always turn and then alarm

- Tool holder is always unable to find the knife position, usually 24 or 0 volts knife restIf it is a station can not find the detection switch is broken

- Q: In front of the turret with rear turret in the car to count the G41G42 cutter compensation when there is no difference?

- The operator is standing in front of the numerical control lathe, the cutter head is located between the main shaft and the operator. When the tool spindle is rotating, the tool head is turned upward, and the cutter head is rotating. The front and rear turret turret programming is the same, clockwise and counterclockwise circular interpolation G02 interpolation G03 direction is right according to the Descartes coordinate system, first determine the positive direction of the Y axis, and then from the positive direction of Y in the negative direction seems to determine the positive direction of the X axis, and then determine the G02 and G03 in the direction of the XZ plane can be, in front of the turret Y positive axis down, rear turret Y positive axis upward. No matter what the system is the same, if you in the right direction according to the right to see Descartes coordinate system can determine G02 and G03 in the front and rear turret style the same, the Y axis is a virtual axis lathe, there is practically no Y axis.

- Q: What is a tray roll bag

- Super large PE bag (tray bag, tray roll bag, super PE even roll bag): for the industrial production of super large PE bag, super PE roll bag.The utility model is mainly used for the packing of the pallet goods, various Super machinery, the packing of the goods, and the waterproof leakage proof of the swimming pool and the related buildings. Available for various specifications, various forms of super Dalian roll bag. The work efficiency is effectively improved, and the labor intensity is lightened.Material; PE, aluminized film, shrink film, etc. can be produced according to customer requirements. Maximum size; 8m/36m bag shape; top opening, side opening, m side, etc..

- Q: The development trend of numerical control tool holder

- Vertical tool holder has four, six stations in the form of two, mainly for simple CNC lathe; horizontal tool holder has a position of eight, ten, twelve, can be positive and opposite direction rotation, the nearest election knife for the full function CNC lathe. In addition, the horizontal tool holder is provided with a hydraulic tool holder and a servo driving tool holder.

- Q: Tool holder S solution

- The bearing force is even and strong, the center of gravity of the s frame is low, the stability of the slide is stable

- Q: However, No. 2, No. 3, the normal use of potential energy on the knife No. 4 can not be normal use of the rotation has not stopped on the 1.

- There is a problem with line 4, the signal is not detected

- Q: Lathe machining slender workpiece should be matched with the knife

- The utility model relates to a tool holder, which is used as a universal tool for a lathe, which is used for supporting the workpiece near the cutting point of the cutter and longitudinally moving with the tool carriage. Contact with the tool and the workpiece support at a general wear resistant ductile iron or bronze, circular support, should be in the car with coarse cylindrical grinding, so as not to scratch the workpiece, the turret can affect the radial cutting force and workpiece weight offset processing, thereby reducing the deformation of workpiece and cutting vibration however, careful attention must be paid to the adjustment, consistent with the tool center and machine center.

- Q: How do you know how to install the roller skates?

- If you are able to disassemble the wheel of the kind of one-piece knife, the general is divided into 165 holes and the distance between the 195 holes, the general number of roller skates is the distance between the 165 holes of the.When installing tool holder is according to personal habits, but most were filled with the knife knife mounted on the middle sole. That is, the wheel is about the same length as the shoe. This is more comfortable. Of course, there are special requirements in order to toe and heel action to do better, but also will be installed on the front or back.

Send your message to us

knife seat,F-KB015 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords