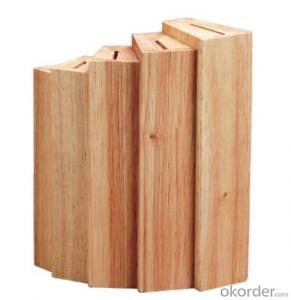

knife seat,F-KB064 white painted pine knife seat

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

N.W.:1.058kg

MEAS:21.5*15*8cm

Key Specifications/Special Features:

Size can be customized

Can print your design of packing

Various styles for choice

Can print your design of packing

Small quantity order is accepted

We also have other knife seat for choice

Our advantages:

All of our products are made by our experienced team of hard working artisans in a safe and responsible environment.

We take great pride not only in the outstanding quality of our products but also in the environment in which they are made

Every product that bears our name was made in an ethically and socially responsible way

Treated by high temperature, making our product antibacterial

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: How to install CNC machine tool

- Side frame installation(1) remove the strip, the pressure plate, cleaning the guide rail and other processing surface, check the defect and put on the lubricating oil.(2) the connecting piece of the tool holder and the counterweight, such as the bearing, the pulley (or the chain wheel), the axle, the hanging rope or the chain, and so on.(3) the stone school F on the positive exploration in wood, clean school guide surface, with lubricating oil, the side head hanging on it, slowly close to the school with positive guide, strip, plate, preliminary adjustment guide clearance, connection lifting mechanism.(4) connect the counterweight and the side of the turret, rose hand operation knife, check whether there is blocked, demolition of timbers.

- Q: How to do the slide shoe

- A few days ago did not see that the answer is late, sorry! You are flat shoes? If so, can the nail be taken out? If you can not get out, such as the two floor, said the first to use an electric drill to destroy it (beware of injury to the knife). If you can take out but not screwed tight, you can find a pair of casual shoes (is that the plastic knife style kids skating shoes), the shoes on the nail are two sides of screw thread nail (nail is not the same as the flower of peace), can not rely on the original screw tightening tool wear nail; but the best in the middle of a cushion spring washer what, lest loose danger.

- Q: The difference between the center and the rest

- 1, the processing of slender ladder axis of the outer circle, the center will be generally supported in the middle part of the shaft, the first car to the right side of the outer circle, turn around after the same clip and then the other side of the car.2, the processing of long axis or long cylinder (such as oil cylinder) of the end, and the end of the hole and thread, etc., can be used to clamp the workpiece left end, with the support of the right end of the center or the right side of the center.3, with the knife with the knife body moves in the same direction is usually positive (refers to the normal turning chuck for car steering), slender shaft the most appropriate; while the center frame fixed position, position adjustment is not usually done in one procedure, just be used to strengthen the rigid support car parts

- Q: What is the difference between the KSJ and HV

- Far, the accuracy of the KSJ knife, the quality is much higher than the HV, the price in that bad! But I'm talking about genuine

- Q: What is the tool rest

- The tool holder is arranged in order to prevent the workpiece from being bent and deformed when the workpiece is cut by the cutter, so that the diameter of the part is larger. Is in the process of moving together with the head.

- Q: Is the plastic knife holder of roller skate good or metal knife holder good?

- Composite material FRAME (domestic said knife), with a certain flexibility, impact resistance, elastic.Metal materials FRAME generally use aluminum alloy. But there is a big difference in material selection. As we all know, aluminum alloy doors and windows are also made of aluminum alloy, aircraft wings are also made of aluminum alloy, therefore, do not blindly follow the aluminum alloy FRAME.Of course, the so-called composite material produced by too many factories in China, in fact, is the most basic plastic. I don't say much about the quality.Plastic, or metal, depending on how you play.Extreme roller skates have no full metal FRAME. And now the mainstream of the 7000 basic models of aluminum alloy.

- Q: Numerical control lathe tool holder does not match the system cutter number

- The turret operation is not in place (sometimes appear suddenly, the mid position stay) is mainly due to signaling disc contact and elastic sheet contact displacement, namely the cutter disc position signal to a fixed offset bakelite. At this point, it should be adjusted to the contact position of the contact plate and the elastic plate. If you still can not rule out the fault, it is possible to send the disk clamping nut loose, resulting in the location of mobile.

- Q: What is the difference between numerical control tool holder and power tool holder

- CNC turret is a large class, which includes the common tool holder and power tool, that is, the power tool holder is one of the numerical control.The common tool holder can only be installed with a fixed knife seat for processing, the power tool holder can be installed with a fixed knife seat, and a power knife holder can be installed.CNC turret is an auxiliary device for CNC lathes are the most common, it can make the CNC lathe in clamping a workpiece in many or even all of the machining process, to shorten the processing auxiliary time, errors caused by multiple workpiece reduce machining process, thereby improving the machining efficiency and high precision machine tool.At present, the domestic CNC turret to electric, divided into two types of vertical and horizontal. Vertical tool holder has four, six stations in the form of two, mainly for simple CNC lathe; horizontal tool holder has a position of eight, ten, twelve, can be positive and opposite direction rotation, the nearest election knife for the full function CNC lathe. In addition, the horizontal tool holder is provided with a hydraulic tool holder and a servo driving tool holder.

- Q: Lathe machining slender workpiece should be matched with the knife

- Choose reasonable tool angle; in order to reduce the radial cutting force, should choose the larger main angle; the front cutter surface should be grinded chipbreaker R=1.5-3mm, the chip flow surface to be machined; the tool surface roughness to be small, and keep a sharp cutting edge.

- Q: The difference between the tool holder and the electric tool holder

- Methods with 980 for example: the first knife in the knife up one page T0010 for the input of X0Z0 cutter compensation in T0020 dabbler cutter compensation second page cutter compensation input X0Z0, the rest of the line.

Send your message to us

knife seat,F-KB064 white painted pine knife seat

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords