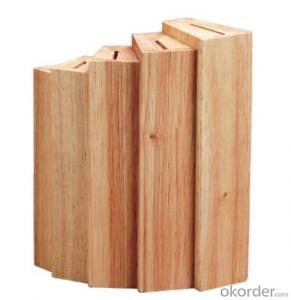

Hot Sale Non-stick Colorful Knife Set

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 sets set

- Supply Capability:

- 1000000 Set set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Hot Sale Non-stick Colorful Knife Set

INCLUDING:

1 PC OF 6'' CHEF KNIFE-1.5MM

1 PC OF 3.5'' PARING KNIFE-1.2MM

1 PC OF 5'' UTILITY KNIFE-1.2MM

1 PC OF CHOPPING BOARD(29.5*19.5*0.3CM)

PACKING: DOUBLE BLISTER

HANDLE:COLOR PP HANDLE.

Advantage Of Hot Sale Non-stick Colorful Knife Set:

1.Good Quality :Made of 100% food grade Material.

2.Competitive price: We always support our customers’ business with competitive price.

3.Good Service : We treat clients as friend.

4.Low MOQ: It can meet your promotional business very well.

5.OEM Accepted : We would be glad to help develop your new design product item.

Usage of Hot Sale Non-stick Colorful Knife Set:

Family used, hotel, restaurant, wedding party, supermarket, retail shop, promotion, gift etc.

Our factory supply all kinds of stainless steel tableware, west tableware, cutlery set, gifts tableware,Kitchen utensils,Kitchen knives,pot.style variety, exquisite workmanship, beautiful and practical, suitable for restaurants or home use, made of high quality stainless steel and high quality, of the production process can be high temperature sterilization, used for a long time, plans to welcome new and old customers to sample processing customized, we will with the fastest speed to reward all the customers the best quality!

Remark of Hot Sale Non-stick Colorful Knife Set:

Every terms mentioned above are flexible.

The products in our company can respond to your requirement, no matter the size, length, thickness, the material, even the packing details. We hold on the principle of "meet every requirement of our customers".

I am sure you can find the one you like.

Company Profile of Hot Sale Non-stick Colorful Knife Set:

We have been making cutlery sets and kitchenware for many famous brands all over the world. Our team consists of hundreds of experienced and well-trianed technicians, so we can fast respond to customers' large quantity demand on high quality products.

- Q: How to install CNC machine tool

- Vertical turret mounting(1) open the guide strip and press plate on the cutter holder, clean the guide rail and the processing surface, check the guide rail surface should be intact without rust.(2) the left and right vertical turret respectively with lifting beam, with oil on the rail surface, the gear transmission is to mobile tool beam assembly hole, mounted on the plate, strip, slide clearance adjustment.(3) the vertical shaft of the vertical cutter head is installed, and the compression member of the balance hammer is removed, so that the counterweight is balanced.

- Q: How can we remove the NC turret

- This is not more than the ordinary lathe CNC lathe, if so simple to take out, it is difficult to achieve automatic change

- Q: How to save the supermarket roll bag?

- In the place of the roll bag placed in the food and goods, dry and wet varieties, such as the separation of each line of the front of the sale of things, do not half-way and tail placed, mainly with the sale of goods placed matching

- Q: Oblique bed CNC lathe in the row on the turret mounted electric turret, and then install the power head, you can also install the tailstock, I do not know this? Cheap not?

- It seems that the tail frame can not be installed, loaded up is not much significance other can be installed at least 120 thousand or more

- Q: CNC lathe tool holder four and six stations which good

- Four station problem seems to be more than six station problem, from my factory 16 sets of 20, 30 numerical control, rigid and rotary accuracy of six stations, good use

- Q: The development trend of numerical control tool holder

- Vertical tool holder has four, six stations in the form of two, mainly for simple CNC lathe; horizontal tool holder has a position of eight, ten, twelve, can be positive and opposite direction rotation, the nearest election knife for the full function CNC lathe. In addition, the horizontal tool holder is provided with a hydraulic tool holder and a servo driving tool holder.

- Q: What is the tool rest

- Auxiliary device for rotating workpiece with radial support. During machining, the workpiece moves axially along with the tool.

- Q: What is the difference between the tool holder of the CNC machine tool and the horizontal lathe

- CNC machine tool holder and horizontal lathe tool holder?Please improve the problem. This question can not answer, do not know what you ask

- Q: CNC lathe tool holder clamping bit how to clip

- The drill chuck can be arranged on the knife tower only by processing a drill handle, and a straight shank drill is arranged on the drill chuck.

- Q: What is the material of the cutting tool

- One, the tool holder commonly used materials:High carbon steel is often referred to as tool steel, mainly used in the manufacture of cutting tools, etc.. The characteristics of its carbon content from 0.60% to 1.70%. is hard and brittle, can be quenched. Hammers, crowbars and other by carbon 0.75% steel; cutting tools such as drills, taps, reamers, made of carbon steel 0.90% to 1%. High hardness (HRC60 65) and good wear resistance can be obtained after heat treatment. 2, under the condition of annealing hardness is moderate, has good machinability. 3, easy access to raw materials, low production costs.Two, blade commonly used materials:1, high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements.2, tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than.3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2003 |

| Annual Output Value | Above US$6 Million |

| Main Markets | Northern Europe; North America; South America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou; Shenzhen |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 300-500 People |

| Language Spoken: | Chinese,English |

| b) Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Hot Sale Non-stick Colorful Knife Set

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 sets set

- Supply Capability:

- 1000000 Set set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords