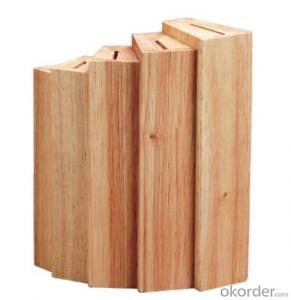

knife seat,F-KB058 black painted pine knife seat

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

N.W.:1.228kg

MEAS:23*16.5*10.5cm

Key Specifications/Special Features:

Size can be customized

Can print your design of packing

Various styles for choice

Can print your design of packing

Small quantity order is accepted

We also have other knife seat for choice

Our advantages:

All of our products are made by our experienced team of hard working artisans in a safe and responsible environment.

We take great pride not only in the outstanding quality of our products but also in the environment in which they are made

Every product that bears our name was made in an ethically and socially responsible way

Treated by high temperature, making our product antibacterial

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

Main Export Markets:

Eastern Europe North America

Mid East/Africa Central/South America

Asia Western Europe

Australasia

- Q: How can we remove the NC turret

- First remove the inside, then the following,Two screws inside, then the eye, should use a punch, turn down

- Q: Why do you want to use the center frame and the tool holder when machining the slender shaft?

- Because, when processing the slender shaft, the process system rigidity problems, mainly for the slender shaft rigidity is low, the cutting force (radial force) under the action of bending deformation (elastic deformation), car axle, a middle drum. The center frame or the tool holder is used to counteract the radial cutting force and increase the rigidity of the slender shaft.

- Q: Who has any good method or fixture drawings and pictures for younger brother to learn ah, do not be grateful, want to do, but I have not seen this thing, the idea does not come out

- In order to install the taper shank drill, you need to buy or process a tooling, the taper of the inner hole 1:16, the size of the outer circle is determined by the hole of the boring tool holder on your lathe.

- Q: The difference between the tool holder and the electric tool holder

- The difference is that there is only one knife library, is T0101, if you want to use a few knives, that is, 02 or more behind the T01 can do it!The use of a knife is equivalent to a knife with a few different knife. Composite tool like, so when the knife changing electric turret is a knife with knife fill, in row knife, are the same, just change the knife cutter compensation and the same time, in different knife position input tool repair line. The first row tool change, T0101 knife, T0102 knife in front of the dabbler, unchanged.To row knife knife, if you want to T0101 the knife, put a knife to a knife or light near the end, directly in the 01 hit patch which according to the Z0 input, the outer circle is, what is the volume of just the tool compensation which according to the X.. Input, to second to third or more the knife is the same; but when to must put the numbers in the cutter compensation go to a knife, or otherwise useless.The tool holder is four knife library, to use a knife is T0101 or T0202.T0303.T0404. The two is not mixed with the.

- Q: CNC lathe tool holder clamping bit how to clip

- If it is turret turret, machine tool manufacturers with drill sets, you can directly install straight shank drill, but the specification is not complete.

- Q: The first reason is that the cutter shaft of the motor shaft is broken for a shaft / how long it will not be able to die!

- Adjust the parameters, the tool change time and lock time, try!

- Q: What is the material of the cutting tool

- First say blade. Commonly used materials: 1 high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements. 2: tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than. 3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

- Q: How do you know how to install the roller skates?

- If you are able to disassemble the wheel of the kind of one-piece knife, the general is divided into 165 holes and the distance between the 195 holes, the general number of roller skates is the distance between the 165 holes of the.When installing tool holder is according to personal habits, but most were filled with the knife knife mounted on the middle sole. That is, the wheel is about the same length as the shoe. This is more comfortable. Of course, there are special requirements in order to toe and heel action to do better, but also will be installed on the front or back.

- Q: The difference between the turret and the rear turret NC lathe

- The classification processing example scope advantages and disadvantages of different composition of 2.3 ordinary lathe and CNC lathe CNC lathe uses a directory of the two introduction 2.1 CNC lathe 2.2 CNC lathe 2.4 CNC lathe 2.5 CNC lathe CNC lathe CNC lathe 2.6 three 3.1 NC turning process and tooling 3.2 CNC lathe programming 3.3 part four references

- Q: CNC machine tool can be drilled hole how to center

- Find a good car end cars to X0, change bit

Send your message to us

knife seat,F-KB058 black painted pine knife seat

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords