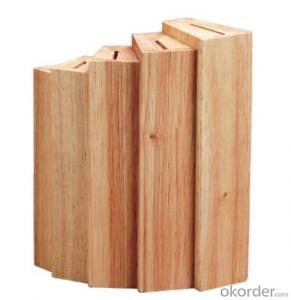

knife seat,F-KB007 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

product name:acacia wood knife seat

material:acacia wood

N.W.:1.532kg

MEAS:24*16*13cm

Specifications:

Has the quite distinct shape of the mountain wood grain, and the contact surface is a good sense

Excellent toughness, process into various curved according to the needs , full of beauty

Solid texture,manufactured goods with firm structure,prolonged service life

The texture of rubber wood is fine and closely woven,pore full of lots ot padding so it's hard to absorb water and corrode.

Description:

1、The knife seat use material of high quality natural acacia wood and take professional advanced machine equipment and manual binding.

2、The knife seat was refined by material, assembly, polishing, painting and other procedures.

3、The knife holder has the advantages of real materials, excellent workmanship, mouldproof and moth proofing, anti bacteria, wear-resisting etc.

4、Hoteam commerce co.,LTD,is a manufactory specialized in all kinds of wood knife handles,wood seats,chopping boards and other woodworks.

5、Because the knife tool contact with tool wet food for long time, is very easy to breed bacteria, you should ensure that dry and clean and put it in the open air

acacia wood knife seat quantity:

Safety, health, bright color,durable,the everyday necessary good products

Anti-mildew change,anti moth

Environmental protection,no crack,no decay

Primary Competitive Advantages:

Brand-name Parts Country of Origin

Distributorships Offered Experienced Staff

Form A Green Product

Guarantee/Warranty International Approvals

Packaging Price

Product Features Product Performance

Prompt Delivery

- Q: NC turret is not in place

- The switch of the tool holder (the encoder or the encoder) is loosened and displaced.First manually pull the motor rotation, so that the tool holder is in position, in the system diagnostic interface to view the cutter position signal, back and forth rotation of the tool holder switch, so that the current knife position signal in the diagnostic page display, and then tighten the tool holder switch.One more word, position detection in ordinary turret is actually a switch, just a different type, divided into contact and contactless or integrated multi position switch, and can not complete the encoding encoding, is in the NC system, called frame encoder has high technology content, the price is much more expensive. The knife switch is not worth some money.

- Q: What is the difference between NC machine tool and tool holder

- In front of the turret with rear turret X axis is not the same, the general system programming does not have what difference, the front turret program got rear turret lathe bed on the same processing, but also have different, like Beijing DTM window system, front and rear arc knife tool that is just the opposite.

- Q: Why do you want to use the center frame and the tool holder when machining the slender shaft?

- When machining slender shafts, use the center frame and the tool holder for the following reasons:First, the use of the central support of the vehicle shaft1, the central frame is directly supported in the middle of the workpiece when the workpiece can be segmented, the center of the support in the middle of the workpiece, so that the support, L/d value reduced by half, slender shaft turning rigidity can be increased several times. Before the work piece is installed on the center frame, it must be in the middle part of the blank to produce a part of the support of the central support of the groove, the surface roughness and cylindricity error is small, otherwise it will affect the accuracy of the workpiece.Two, the use of the tool holder with the support of the fine axisWith the tool holder fixed on the bed saddle, there are generally two supporting claws, with the tool holder can follow the movement of the tool to offset radial cutting can increase the stiffness of the workpiece, reduce deformation. So as to improve the shape precision and reduce the surface roughness.According to the design principle of the tool holder, only two supporting claws can be used, because the cutting resistance of the lathe tool to the workpiece is F`r, the workpiece is stuck on the two supporting claws of the tool rest. But in actual use, the workpiece itself has a downward gravity, and bending workpiece inevitably therefore, when turning the workpiece, often due to centrifugal force instantaneous left supporting claw, a supporting claw contact vibration. If the three supporting claws are used to support the workpiece, the workpiece is supported by a lathe tool, so that the upper and the lower parts of the workpiece can not move, and the turning is stable, and the vibration is not easy to generate. Therefore, when the car is fine to find a very critical problem is to use the shaft with three claws.

- Q: Who has any good method or fixture drawings and pictures for younger brother to learn ah, do not be grateful, want to do, but I have not seen this thing, the idea does not come out

- Very simple, find a square on the grinder grinding angle four straight, like a knife, much bit big hole, the drill bit into a wire on the bit in the next attack on the line, but straight shank drill.

- Q: However, No. 2, No. 3, the normal use of potential energy on the knife No. 4 can not be normal use of the rotation has not stopped on the 1.

- The four bit Holzer component is broken, or the number four is a problem

- Q: What are the parts of the lathe and tool holder

- A lathe is a machine with many parts assembled.A part of a lathe.

- Q: 4 station tool structure is the best. The detailed process of mechanical transmission, their demolition a few times, the worm brake to lift the knife. There is a problem in the rise of the knife in the process of the top cap of the spring to the top of the iron cover dead, the result of the death of the knife holder, can not drive. I estimate that the top cap and the angle and the first bevel on the iron cover are not consistent due to wear and tear. For I a person's opinion, hope you enlighten me

- This thing to have a picture to explain, the text can not express. Remove the countless times, the rotation of the motor makes the knife rises and then rotating, on top of a Hall element to detect the Holland tool you need is not to, to the motor reversal, falling knife stuck in the tooth is motor locked dead. There is a spring in the middle of the shaft and drives the two clips to play a key role. A lot of reasons for the death of the tool holder are caused by the broken line in the middle.

- Q: What is the material of the cutting tool

- First say blade. Commonly used materials: 1 high speed steel (also known as Feng Steel, Bai Gang): is a kind of tungsten, chromium, vanadium, molybdenum and other high alloy tool steel more elements. 2: tungsten carbide hard alloy by high hardness and melting point, titanium carbide and cobalt cemented metal made by powder metallurgy method, the hardness and wear resistance are good, hot hardness is very high, so the cutting speed is higher than high speed steel several times or even several times, can cut material of high speed steel no processing method, but the bending strength and impact toughness of high speed steel much worse than. 3, ceramics: alumina powder sintered at high temperature and the ceramic blade, the hardness, wear resistance and heat resistance are higher than the cemented carbide.

- Q: Why do you want to use the center frame and the tool holder when machining the slender shaft?

- When machining slender shafts, use the center frame and the tool holder for the following reasons:First, the use of the central support of the vehicle shaft1, the central frame is directly supported in the middle of the workpiece when the workpiece can be segmented, the center of the support in the middle of the workpiece, so that the support, L/d value reduced by half, slender shaft turning rigidity can be increased several times. Before the work piece is installed on the center frame, it must be in the middle part of the blank to produce a part of the support of the central support of the groove, the surface roughness and cylindricity error is small, otherwise it will affect the accuracy of the workpiece.Two, the use of the tool holder with the support of the fine axisWith the tool holder fixed on the bed saddle, there are generally two supporting claws, with the tool holder can follow the movement of the tool to offset radial cutting can increase the stiffness of the workpiece, reduce deformation. So as to improve the shape precision and reduce the surface roughness.According to the design principle of the tool holder, only two supporting claws can be used, because the cutting resistance of the lathe tool to the workpiece is F`r, the workpiece is stuck on the two supporting claws of the tool rest. But in actual use, the workpiece itself has a downward gravity, and bending workpiece inevitably therefore, when turning the workpiece, often due to centrifugal force instantaneous left supporting claw, a supporting claw contact vibration. If the three supporting claws are used to support the workpiece, the workpiece is supported by a lathe tool, so that the upper and the lower parts of the workpiece can not move, and the turning is stable, and the vibration is not easy to generate. Therefore, when the car is fine to find a very critical problem is to use the shaft with three claws.

- Q: What is the reason why the turret of NC lathe is not maintained?

- May rest inside the lines are wrong, may also have a lid on the knife frame out

Send your message to us

knife seat,F-KB007 acacia wood knife seat,your best choice

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords