China Knives Set Hollow Handle

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 sets set

- Supply Capability:

- 10000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of China Knives Set Hollow Handle

INCLUDING: 1 PC OF 8'' CHEF KNIFE-2.5MM

1 PC OF 8'' BREAD KNIFE-2.5MM

1 PC OF 8'' SLICER-2.5MM

1 PC OF 5'' UTILITY KNIFE-2.0MM

1 PC OF 3.5'' PARING KNIFE-2.0MM

1 PC OF SHARPNER

1 PC OF SCCIORS

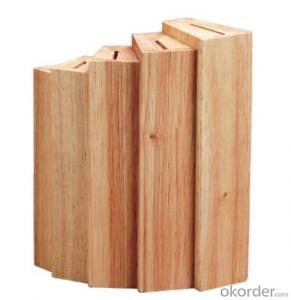

1 PC OF ACRYLIC BLOCK.

HANDLE:HOLLOW HANDLE WITH BLACK PAINTING.

MATERIAL:2CR14

Advantage Of China Knives Set Hollow Handle:

1.Good Quality :Made of 100% food grade Material.

2.Competitive price: We always support our customers’ business with competitive price.

3.Good Service : We treat clients as friend.

4.Low MOQ: It can meet your promotional business very well.

5.OEM Accepted : We would be glad to help develop your new design product item.

Usage of China Knives Set Hollow Handle:

Family used, hotel, restaurant, wedding party, supermarket, retail shop, promotion, gift etc.

Our factory supply all kinds of stainless steel tableware, west tableware, cutlery set, gifts tableware,Kitchen utensils,Kitchen knives,pot.style variety, exquisite workmanship, beautiful and practical, suitable for restaurants or home use, made of high quality stainless steel and high quality, of the production process can be high temperature sterilization, used for a long time, plans to welcome new and old customers to sample processing customized, we will with the fastest speed to reward all the customers the best quality!

Remark of China Knives Set Hollow Handle:

Every terms mentioned above are flexible.

The products in our company can respond to your requirement, no matter the size, length, thickness, the material, even the packing details. We hold on the principle of "meet every requirement of our customers".

I am sure you can find the one you like.

Company Profile of China Knives Set Hollow Handle:

We have been making cutlery sets and kitchenware for many famous brands all over the world. Our team consists of hundreds of experienced and well-trianed technicians, so we can fast respond to customers' large quantity demand on high quality products.

- Q: Numerical control lathe tool holder is a tool to change what is the fault

- It should be blocked to form the motor overload, the method is verified about CNC lathe turret and motor out, if not the normal disc worm that is stuck to the machine, can be disassembled in accordance with the instructions of disassembly tool, check the internal parts to see if there is deformation coupling and so on because, in many cases is mechanical clamping due to collision deformation.CNC lathe: CNC lathe, also known as the CNC lathe, that is, computer numerical control lathe, is China's largest use, the most extensive coverage of a CNC machine tools, accounting for about 25% of the total number of CNC machine tools. A set of mechanical, electrical, hydraulic, pneumatic, microelectronics and information technology as one of the integrated mechanical and electrical products. Has the advantages of high precision, high efficiency, high automation and high flexibility for manufacturing equipment in machine tools.

- Q: CNC lathe turret, sometimes why turn around.

- The general is a knife or bad coder and encoder connected to the data line broken, not to signal transmission system, data line control box is connected behind the knife and broken, suggest that you have the knife line reconnected or knife encoders change try, data line if is not the knife and the back of the control box is connected with a break

- Q: Tool holder S solution

- The bearing force is even and strong, the center of gravity of the s frame is low, the stability of the slide is stable

- Q: CNC turret can be turned into 45 degrees ah? Can you turn counterclockwise?

- For the eight position of the tool holder, every turn a station just turn 45 degrees.Can you turn counterclockwise? This depends on the structure of the turret, some can, some can not. The 4 position and the 6 position of the tool holder with the Holzer element as the detection signal can not be selected by the nearest knife. The utility model adopts an encoder as the detection signal of the electric tool holder and a proximity switch as the hydraulic head of the detection signal. The nearest knife also need to prepare the appropriate PLC ladder diagram.

- Q: What is the tool rest

- The tool holder is arranged in order to prevent the workpiece from being bent and deformed when the workpiece is cut by the cutter, so that the diameter of the part is larger. Is in the process of moving together with the head.

- Q: What is the difference between numerical control tool holder and power tool holder

- Seems to be a thing. The knife of CNC machine tool CNC turret should refers to the (for the realization of automatic tool change in the process), can be divided knife straight row knife, disc knife, knife and other bamboo hat.

- Q: Lathe machining slender workpiece should be matched with the knife

- The reasonable choice of cutting parameters; turning slender shaft, the cutting amount should be less than the ordinary shaft parts, with the hard alloy lathe rough car and then left the amount of fine grinding grinding to size requirements.

- Q: The rotary tool holder is marked with the knife number. How to define the knife number?

- There is no knife in the actual sense of the knife number, because it is to use the knife to determine the use of the.

- Q: CNC machine tool can be drilled hole how to center

- 1, do not need to set the coordinate system (the center), is loaded with a knife, in the process of preparation of processing requirements, reasonable adjust the height and verticality, the proper use of speed and feed rate, the knife tool can be set, simple, can fix a hole.2, if the degree of difficulty and high requirements, please use the circular drilling instructions programming.

- Q: Why do you want to use the center frame and the tool holder when machining the slender shaft?

- When machining slender shafts, use the center frame and the tool holder for the following reasons:First, the use of the central support of the vehicle shaft1, the central frame is directly supported in the middle of the workpiece when the workpiece can be segmented, the center of the support in the middle of the workpiece, so that the support, L/d value reduced by half, slender shaft turning rigidity can be increased several times. Before the work piece is installed on the center frame, it must be in the middle part of the blank to produce a part of the support of the central support of the groove, the surface roughness and cylindricity error is small, otherwise it will affect the accuracy of the workpiece.Two, the use of the tool holder with the support of the fine axisWith the tool holder fixed on the bed saddle, there are generally two supporting claws, with the tool holder can follow the movement of the tool to offset radial cutting can increase the stiffness of the workpiece, reduce deformation. So as to improve the shape precision and reduce the surface roughness.According to the design principle of the tool holder, only two supporting claws can be used, because the cutting resistance of the lathe tool to the workpiece is F`r, the workpiece is stuck on the two supporting claws of the tool rest. But in actual use, the workpiece itself has a downward gravity, and bending workpiece inevitably therefore, when turning the workpiece, often due to centrifugal force instantaneous left supporting claw, a supporting claw contact vibration. If the three supporting claws are used to support the workpiece, the workpiece is supported by a lathe tool, so that the upper and the lower parts of the workpiece can not move, and the turning is stable, and the vibration is not easy to generate. Therefore, when the car is fine to find a very critical problem is to use the shaft with three claws.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1905 |

| Annual Output Value | Above US$2 Million |

| Main Markets | Northern Europe; North America; South America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Guangzhou; Shenzhen |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 200-300 People |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | Above 7 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Hig; Average |

Send your message to us

China Knives Set Hollow Handle

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 sets set

- Supply Capability:

- 10000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords