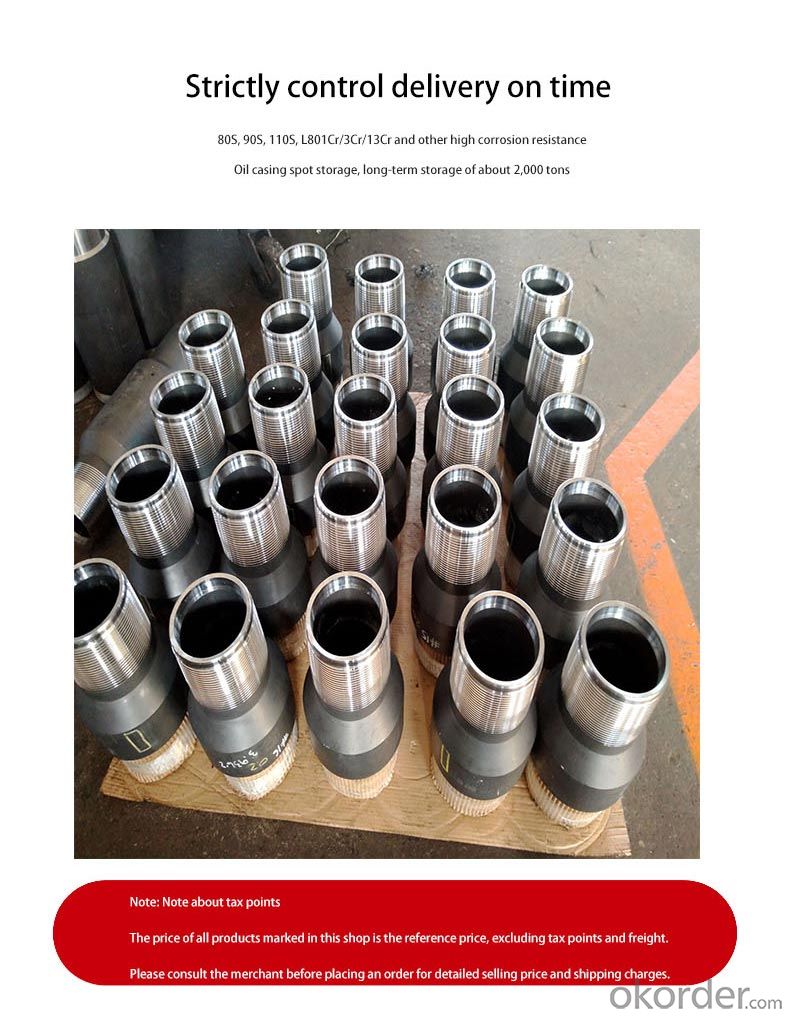

J55-P110 Grade Longkailai Couplings, Spot Supply, Strong Sealing, Affordable Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

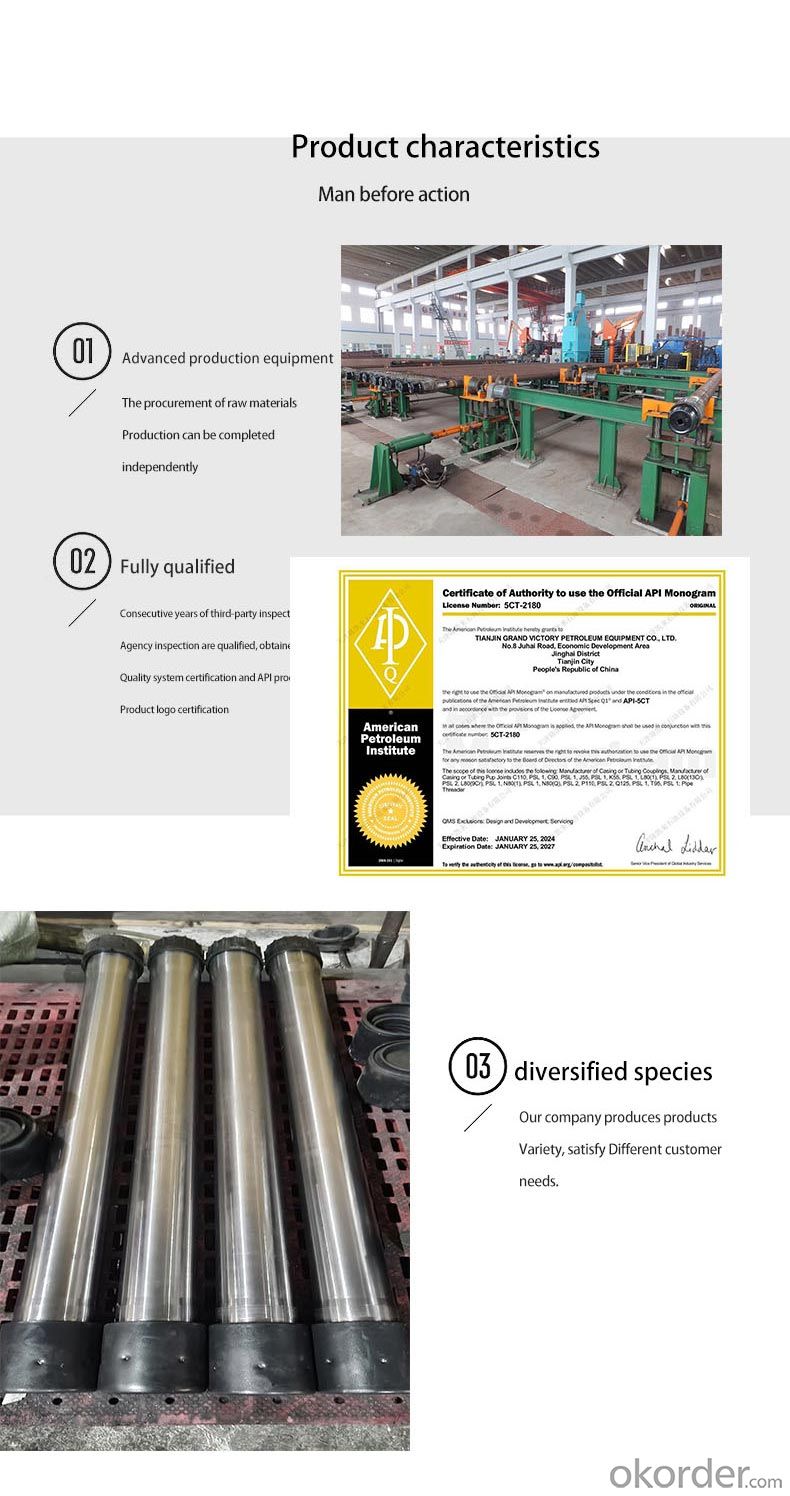

API 5CT J55/N80/P110 OCTG Casing & Tubing Manufacturer Direct

Comprehensive OCTG Solutions for Every Well Profile

As an API-licensed manufacturer, we eliminate intermediaries to deliver J55/N80/P110 casing and tubing with 15% cost savings. Our vertically integrated production process ensures full traceability from steel billet to finished product.

Technical Specifications

Material Science:

J55: 0.45% Mn, 0.25% C composition for shallow wells (≤8,000ft TVD)

N80: Quenched & tempered microstructure withstands 12,000psi collapse pressure

P110: 110ksi SMYS with Charpy V-notch impact ≥45J at -20°C

Threading Technology:

CNC-machined API LTC/BTC threads with ±0.003" pitch diameter tolerance

Optional VAM TOP connections for HPHT wells

Quality Assurance:

100% ultrasonic testing (UT) for laminations

Hydrostatic tested to 80% of yield strength

Applications

J55: Water injection wells, surface casing

N80: Intermediate casing in sour gas fields

P110: Production casing in 15,000psi reservoirs

Case Study

A Permian Basin operator reduced casing costs by 18% using our direct-shipment P110 casing for 35 horizontal wells, achieving 95% torque-turn compliance during running

- Q: How are steel pipes used in the construction of highways?

- Steel pipes are commonly used in the construction of highways for various purposes, such as drainage systems, culverts, and sign supports. They provide a durable and efficient solution for transporting stormwater and preventing damage to the road surface. Additionally, steel pipes are utilized to support highway signs and traffic signals, ensuring their stability and longevity.

- Q: Are steel pipes suitable for potable water supply?

- Yes, steel pipes are suitable for potable water supply. They are commonly used for water distribution systems due to their durability, strength, and resistance to corrosion. However, it is important to ensure that the steel pipes are properly coated or lined to prevent any potential contamination of the water supply.

- Q: How are steel pipes cleaned and maintained?

- Steel pipes are cleaned and maintained through various methods. The process typically involves removing any debris or rust from the pipes using wire brushes or sandblasting. After cleaning, a protective coating is applied to prevent corrosion. Regular inspections and maintenance checks are also conducted to identify any potential issues such as leaks or weak points, ensuring the pipes remain in optimal condition.

- Q: Is hot dipped plastic pipe steel?

- The characteristics of hot dipped plastic pipe are:1., hot dipped plastic pipe superior anti-static performance: through the formula to add antistatic agent, so that its internal and external surface resistance value reached and exceeded the national industry standards.2., such as the use of plastic raw materials, add flame retardants. The flame retardant performance index conforms to the national standard, and the steel plastic composite structure has better flame retardance than the pure plastic pipe material, and is suitable for underground inflammable, explosive and other places.3. hot dip coating steel strong adhesion: steel surface after special treatment, curing, coating adhesion is greater than or equal to 30N/10mm.4., dense internal and external resin layer: coating thickness of more than 0.5 mm, no pinholes, with excellent corrosion resistance.The mechanical properties of plastic steel pipe superior 5. hot dip: can withstand the harsh conditions of use: coating steel has good toughness, high mechanical strength, impact bending and other foreign influence, has a strong bearing capacity, has better performance than other mine plastic pipes.6. hot dip steel corrosion and fouling, the fluid resistance is small: corrosion and fouling, especially suitable for the underground conveying high sulfur water and transport of calcium and magnesium plasma water, save the maintenance cost, service life is much higher than that of the other pipe, high economic benefit.7. self lubrication: smooth wall, no fouling, small transmission resistance, under the same conditions, can improve the transport capacity of 30%.8. convenient and reliable connectionThe utility model completely overcomes the defects of the difficult connection of the pure plastic mining materials, and can be connected with the underground steel pipe and the valve by using flanges, fast couplings, etc., and has strong interchangeability.

- Q: Are steel pipes resistant to impact?

- Yes, steel pipes are generally resistant to impact due to their high strength and durability.

- Q: What is the maximum allowable pressure for steel pipes?

- The maximum allowable pressure for steel pipes typically depends on various factors such as the pipe's diameter, thickness, and material grade. Additionally, it is crucial to consider the intended application and the specific industry standards or codes being followed. Therefore, there is no universal answer to this question, as the maximum allowable pressure can vary significantly depending on these factors. It is essential to consult relevant codes and standards specific to the application to determine the appropriate maximum allowable pressure for steel pipes.

- Q: What are the environmental impacts of using steel pipes?

- The environmental impacts of using steel pipes include the extraction and processing of raw materials, such as iron ore and coal, which contribute to deforestation, habitat destruction, and greenhouse gas emissions. The manufacturing process also generates significant amounts of waste, including slag and emissions from steel production. The transportation and installation of steel pipes contribute to carbon emissions, while their corrosion and maintenance may result in the release of toxic substances into the environment. Proper waste management and implementing sustainable practices can help mitigate some of these impacts.

- Q: Can steel pipes be used for high-temperature applications?

- Yes, steel pipes can be used for high-temperature applications. Steel is known for its excellent strength and durability, making it suitable for handling high temperatures. However, the specific grade of steel used and the operating conditions must be considered to ensure it can withstand the desired temperature range without compromising its structural integrity.

- Q: Can the KBG25 steel tube hold 4 six types of cables?

- 1 of the six lines of cross-sectional area of about 25 square millimeters, 4 to 100 flat, KBG25 cross-sectional area of about 490100/490=20.4%, just over the specifications, so short distance and less elbow can be worn. However, due to the construction of pipes are generally not standardized, elbow more, and do not use special elbow (site bending), so KBG25 wearing 4, six kinds of cable are more difficult.

- Q: What is the lifespan of galvanized steel pipes?

- The lifespan of galvanized steel pipes can vary depending on various factors such as the environment, usage, and maintenance. However, on average, galvanized steel pipes can last between 40 to 70 years.

Send your message to us

J55-P110 Grade Longkailai Couplings, Spot Supply, Strong Sealing, Affordable Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords