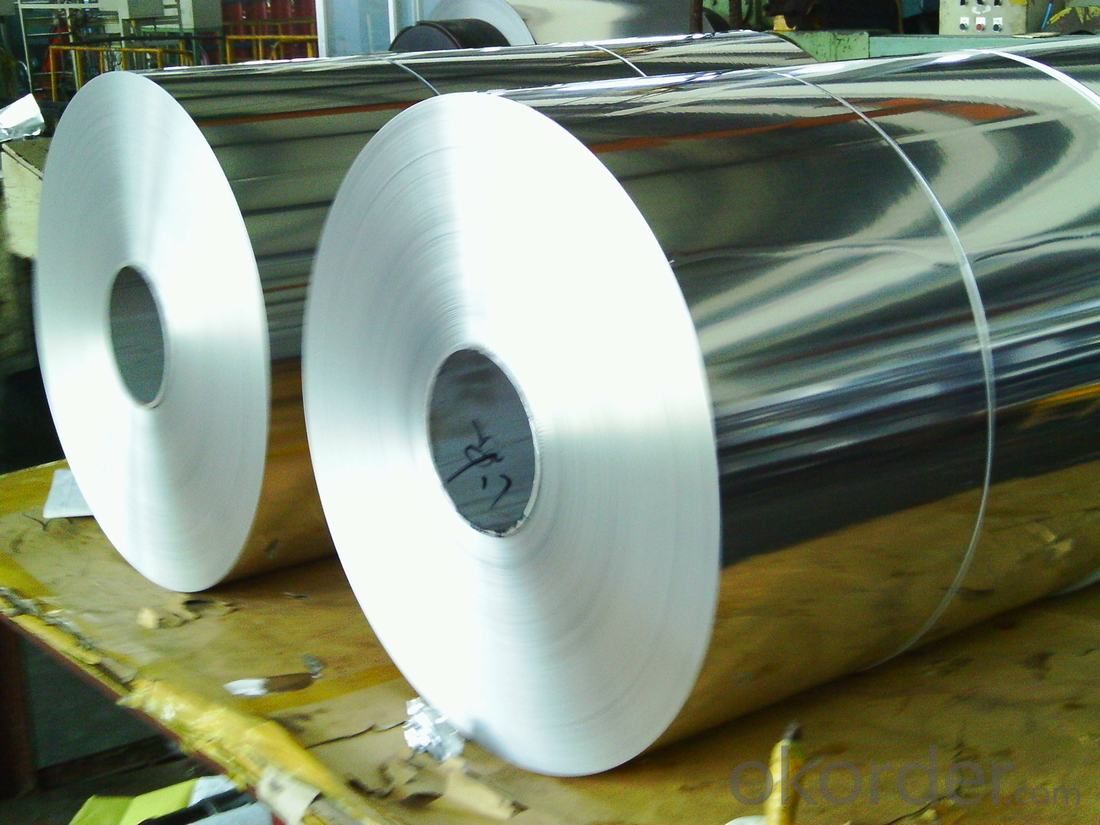

Aluminum Sheets of Metal - ISO Standard Thin Aluminum Strip for Sony Xperia Z1 L39H for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Description

-Hot rolling 1100/1050/1020/1060 aluminum coils for roof sheet is used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

-1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-1500mm

-Length:12m Max.

Temper: h14,h16,h18,h22,h24,h26,h32,o/f

Thickness: o.o3mm-3.0mm

Width: 30mm-1700mm

Coating: pe(polyester),pvdf,epoxy

Painting thickness: standard 16-25 mic, max 40 mic

Color: according to ral colors or customer's samples

Packaging & Delivery

| Packaging Details: | Coil ID :508MM Coil Weight : about 2.5 tons or as per customers requirement Packing ; In Export Sea worhty wooden pallets Eye to wall or Eye to Sky One container can be loaded about 20 mts |

| Delivery Detail: | within 25 days after receiving L/C deposit |

Place | China |

Grade | Aluminium coil & roll |

Alloy | 1100,1050,1060,3003,3105,5052,5083,8011 |

Temper | O,H12,H14,H16,H18,H19,H22,H24 |

Standard | GB/T3 190-1999 GB/T3 190-2003 YS/T 430-2000 |

Width | 15mm-2200mm |

Length | customized avaiable |

Inner Diameter | 75mm,150mm,200mm,220mm,300mm,405mm |

Application | Widely used in air-conditioning,cable,exchanger,cigarettes,food,medicine, decoration,packing,electrical and products,etc. |

Character. |

|

- Q: Are aluminum sheets suitable for outdoor use?

- Yes, aluminum sheets are suitable for outdoor use. Aluminum is a durable and corrosion-resistant material that can withstand various weather conditions, making it ideal for outdoor applications.

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- Aluminium is one of the most abundant Element on earth, ranking 3rd in the crust, second only to oxygen and silicon. And it is eminently recyclable. However, many minerals containing aluminium are not economically exploitable.

- Q: Does aluminum foil keep food warm or cool, or is it just a convenient material to cover food with?

- It can insulate food, depending on how thick it is or how many layers you use. Aluminum foil is multi-functional: 1) Acts as a lid if you don't have one for any pot or pan. 2) As you mentioned: its a convenient material to cover food. 3) Can be used for lining the drip tray on your stove top for easy clean up. 4) Can be used as a non-stick liner for sheet pans when baking cookies or brownies. 5) Fish can be wrapped in aluminium foil and then steamed in the oven.

- Q: Are aluminum sheets suitable for decorative purposes?

- Yes, aluminum sheets are suitable for decorative purposes. Aluminum is a versatile material that can be easily manipulated into various shapes and designs, making it ideal for decorative applications. It can be cut, bent, and formed into different patterns, allowing for endless possibilities in creating decorative elements. Additionally, aluminum sheets can be coated or painted in different colors and finishes to further enhance their aesthetic appeal. Furthermore, aluminum is a lightweight and durable material, which makes it suitable for both indoor and outdoor decorative use. It is resistant to corrosion, ensuring that the decorative elements made from aluminum will retain their appearance and last for a long time. Overall, aluminum sheets offer a wide range of design possibilities and practical benefits, making them an excellent choice for decorative purposes.

- Q: only aluminum source i have is mountain dew cans any way to turn them quickly into a powder?or any other ideas?

- Let me guess, making thermite? :P The easiest way by far to get aluminum I have found is breaking open an old EtchaSketch. That's aluminum powder in there. There are too many impurities on the can to make it easy, go to the dump and find some old EtchaSketches. Addition: Do NOT breathe in the powder, its not good for your system, it does large amounts of damage to your lungs, I suggest wearing a mask of some sort for safety. Do not take it lightly. Otherwise, have fun melting holes in the ground / someone's car / a safe / anything else you can get your hands on :P

- Q: Can 101 aluminum sheets be welded?

- Yes, 101 aluminum sheets can be welded. Aluminum, including 101 aluminum alloy, is commonly used in welding due to its excellent weldability. It is important to note that proper welding techniques and equipment should be used to ensure a successful weld.

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- The typical thermal expansion coefficient of aluminum sheets is approximately 22.2 x 10^-6 per degree Celsius.

- Q: Can aluminum sheets be used for kitchen backsplashes?

- Yes, aluminum sheets can be used for kitchen backsplashes. Aluminum is a versatile and durable material that is commonly used for various applications, including backsplashes in kitchens. It offers several advantages such as being lightweight, corrosion-resistant, and easy to clean. Aluminum sheets can be easily cut and installed, making them a popular choice for modern kitchen designs. Additionally, they are available in a wide range of finishes and colors, allowing homeowners to find a style that complements their kitchen décor. Overall, aluminum sheets are an excellent option for kitchen backsplashes due to their practicality, aesthetic appeal, and ability to withstand the demands of a busy kitchen environment.

- Q: Are 101 aluminum sheets suitable for aerospace tooling?

- No, 101 aluminum sheets are not suitable for aerospace tooling.

- Q: what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- saw web size depends on the thickness and height of sectional material,equipment compatibility and permitted installed saw web size .

Send your message to us

Aluminum Sheets of Metal - ISO Standard Thin Aluminum Strip for Sony Xperia Z1 L39H for Decoration

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 600 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords