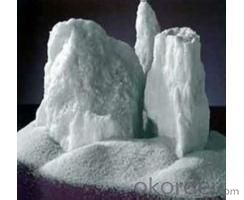

Raw Materials for Refractory:ISO Certified Low Na2O White Corundum/White Fused Alumina Grain with Al2O3 99.2 Min

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 1) 25kg woven bag 2) 25kg paper bag 3)1000kg big bag 4) According to clients' requirement. |

| Delivery Detail: | Within 30 days or depend on the requirement of clients. |

Specifications

White Fused Alumina grain with Al2O3 99.2 min

ISO9001 Certificated

Strong wear and heat resistance

1. Advantage

White fused alumina is made of quality alumina powder by smelting at 2050 °C.

1). High purity

2). Good self-sharpening

3). Less thermal diffusivity in grinding

4). Strong acid-alkali resistance

5).Excellent high-temperature stability,

6). Low porosity, etc

2. Available Size:

Refractory grade:

12-6mm 10-8mm 8-5mm 5-3mm 3-1mm 1-0mm 1-0.5mm 0.5-0mm 0.3-0mm....

80F 100F 120F 150F 180F 200F 240F 270F 320F/325F...

Abrasive Grade:

F8 F10 F12 F14 F16 F20 F24 F30 F36 F40 F46 F60 F80

F100 F120 F150 F180 F220

3. Applications :

A.The abrasive tools: grinding high carbon steel, high-speed steel and chilled steel.

B. Lapping and polishing medium

C. Crucible

D.Steel ladle

E. Catalyst carrier

F. Special ceramics and super refractory materials.

4. Physical Index:

Color | White |

True Density | 3.96g/cm3 |

Bulk Density | 1.75-1.95g/cm3 |

Microhardness | HV2200-2300 |

Mohs Hardness | 9.0 |

Melting Point | 2250°C |

5. Chemical Composition

Typical Value:

Al2O3 | 99.5% |

Na2O | 0.25% |

Fe2O3 | 0.04% |

SiO2 | 0.03% |

Abrasives Grade:

Grit Size | Al2O3 | Na2O |

F12-80 | >99.22% | <0.35% |

F100-240 | >99.0% | <0.4% |

Refractory Grade

Grit Size | Al2O3 | Na2O |

0-1mm | >99.22% | <0.35% |

1-3mm | >99.3% | <0.3% |

3-5mm | >99.3% | <0.3% |

200mesh | >99.0% | <0.4% |

325mesh | >99.0% | <0.4% |

- Q: What are some of the new refractories and what are their characteristics?

- These refractory materials can be bought in Zhengzhou real gold refractory materials factory. If necessary, we can visit the factory in Xinmi first.

- Q: which kind of refractory is used in golden smelting furnace? How about his using temperature

- generally the price of the quartz sand refractory material is higher and the temperature can meet the requirement of 2000 degree.

- Q: What's the poured refractory material?

- Frequently used poured refractory material: AZS brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nonoxide refractories like nitride, silicide, sulfide, boride and carbide, and oxide refractories like calcium oxide, chromium hemitrioxide, alumina, magnesium oxide and beryllia.

- Q: What is the fire endurance of fireproof glass cotton?

- Good thermal insulation and thermal insulation. thermal insulation and thermal insulation depends on the heat conductivity coefficient of glass?silk λ=0.043W/m2K. good fireproof?performance, it's fire-resistant capacity is more than 1000 ℃.

- Q: Which kind of external wall fire barrier zone material is better?

- I recommended foam cement and particulate thermal insulation composite waterproof material, which is fire isolation area product, which uses surface of vertical?plate arranged fiber technology to make the compressive?strength in the vertical direction up to above 80KPa. At the same time, under the conditions of both exterior heat insulation and effects of humiture in the long-term, it can still maintain the non-aging performance of various aspects, and safety (reliability), fire resistance and excellent durability.

- Q: What is the new fireproofing standard of external wall thermal insulation materials?

- 1, The height of fire barrier zone is not less than 300, and the thickness is same to the external insulation system; 2, the horizontal dividing joint should be set on the boundary between fire barrier zone and thermal insulation system; 3, Fire barrier zone is usually set in the horizontal direction, the fire barrier zone should be set above the door and window openings, the distance between the low edge of barrier zone and upward side of the hole should not exceed 500mm; 4, The construction of fire barrier zone insulating layer should carried on from bottom to top with EIFS insulating layer, which is not first leave the place in the EIFS insulating layer, and then paste fire barrier zone insulation board; 5, pasting the insulation board fire barrier zone insulation board and EIFS insulation board should be stitched closely, the width is more than 2mm gap application EIFS insulation materials or fire-retardant foam polyurethane padding;

- Q: What types of steel are silicious quicksand and chromium quicksand used in respectively?

- Chromium quicksand can be used in steel-making process that has longer refining time like LF, VD and RH, in stainless steel drainage and thin plate drainage agent. Silicious quicksand is used in short steel-making process, process that is less than 45 seconds or process without refining. You can consult Hua Heng for details or inspect it by yourself.

- Q: What is neutral refractory? Can refractory suppliers tell the main components of it?

- // Baike? Url x3d CQ3i6_yUCWUMgk3aaRGGLURNtvKPl5IdZpj35Yvommk7Nyif0IJD-SkdIW29GCHwLpb9cT9Ii25GLcEJg-ZHcq "target x3d" _blank "x26gt; http://baike.baidu.baidu.

- Q: who knows the technology of fireproofing material?

- First: Firstly, you should produce the recipe and prepare the raw materials, for example, if you prepare to produce 1 ton, you should compute the recipe sheet of 1 ton producing; check whether the raw materials are complete; second: make the color and filler thick liquid; add water in order and proper auxiliary in a low speed, then put color and filler (generally we should firstly add something with large oil absorption), wash the meachine after putting the powder. Then seperate them for about 20 miutes in a high speed, until the fineness is qualified; of course, if you need sander, i think you only need sino-soviet differential powder material and non-obvious particles. Third: Paint mixing period: after making the color and filler thick liquid, reduce the roll speed into about 600 roll per minute, add emulsion and proper auxiliary, finally adjust PH and viscosity. Liquid solvent paint, pigment paste: Resin,solvent and pigment ---〉pre mixing---〉stick---〉grinding--〉stick--〉packaging, highlight varnish: Resin, solvent ----〉mixing ----〉stick ----〉packaging, sub-gloss varnish: Resin, solvent----〉mixing----〉matting agent,stick----〉packaging, colored?paint: The primary colorant----〉Color matching by auxiliary color paste----〉stick----〉packaging, aluminum?paint: Aluminite powder soaking----〉resin----〉colour modulation, lustre adjusting----〉stick----〉packaging, powder coat: Resin,filler,pigment,auxiliary---〉mixing---〉extrusion---〉cooling---〉smashing---〉sieving---〉 packaging.

Send your message to us

Raw Materials for Refractory:ISO Certified Low Na2O White Corundum/White Fused Alumina Grain with Al2O3 99.2 Min

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords