3D Printing Graphite Electrodes for Industrial Silicon Production - UHP with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

1.Diameter: 200 to 700mm

2.Length: 1600 to 2400mm

3.Nipple:3-4TPI

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

1. Grade: RP, HP, UHP, SHP, RPI

2. Diameter: 200 to 700mm at your choice.

3. Length: 1600 to 2400mm at your choice.

4. Nipple: 3-4 TPI

5. Fine mechanical strength and machining quality, low specific resistance, high temperature and oxidation resistance

6. Low price and timely delivery.

Feature

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

Grades: RP, RPI, HP, SHP, UHP

All graphite electrodes are offered with tapered nipples, i.e. 3 or 4 threads per inch, and meet the internationally accepted tolerances as per NEMA CG 1/ IEC 60239 / JIS R7201 standards.

UHP

Physical and chemical index

Item | Unit | Nominal Diameter(mm) | |||

YB/T4088-2000 | Typical Values | ||||

Industry Standard | |||||

300-400 | 450-550 | 350-550 | |||

Resistance | Electrode | ohm | ≤6.2 | ≤6.5 | 4.6-6.2 |

Nipple | ≤5.5 | ≤5.5 | 3.5-4.5 | ||

Bending Strength | Electrode | Mpa | ≥10.5 | ≥10.0 | ≥11.0 |

Nipple | ≥16.0 | ≥16.0 | ≥18.0 | ||

Elastic Modulus | Electrode | Gpa | ≤14.0 | ≤14.0 | ≤13.0 |

Nipple | ≤18.0 | ≤18.0 | ≤17.0 | ||

Density | Electrode | g/cm3 | ≥1.65 | ≥1.64 | 1.65-1.72 |

Nipple | ≥1.72 | ≥1.70 | 1.75-1.82 | ||

Ash content | Electrode | % | ≤0.3 | ≤0.3 | ≤0.3 |

Nipple | |||||

CTE(100-600) | Electrode | 10-6/C | ≤1.5 | ≤1.5 | 1.20-1.40 |

Nipple | ≤1.4 | ≤1.4 | 1.10-1.30 | ||

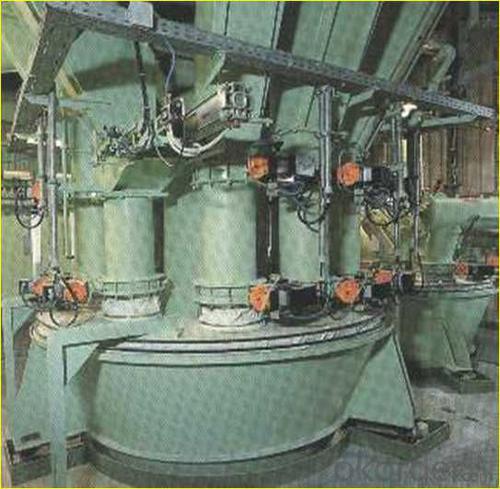

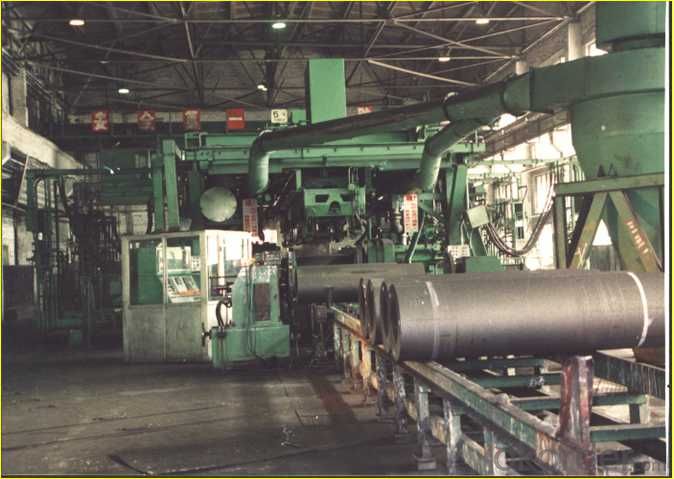

Image

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

FAQ:

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

1. Why it is essential to select electrode carefully for each particular furnace?

The primary factor is the maximum current intensity of the furnace. However, other conditions should also be considered, such as the characteristics of the furnace, type of charge, tap to tap time, oxygen blowing, mechanical requirement, furnace regulation, etc.Generally, specifications for electrodes of most grades have been standardized. Variation of physical characteristics with temperature, however, should be taken into account whenever using the electrodes.

Precautions to the use of graphite electrodes

2. Why it is essential to not to fit electrodes and nipples made by different manufacturers together?

The capacities of the furnace and the transformer determine whether the grade and diameter of the electrode are suitable to the furnace or not.

In order to prevent the electrode column from being hit by the collapsed furnace loads, large and heavy scraps should be loaded onto the bottom of the furnace. Do not put significant quantity of insulating materials such as lime and so on just under the electrode column, otherwise it would be difficult to power on the electrode column, or even break it.

electrode column may be hurt when it moves up and down if the furnace cover is out of the position.

When making a connection, lost or damaged pitch plugs must be replaced.

The reason must be found out if a gap appears between two electrodes after connection. The electrode column can only be loaded after the gap being eliminated.

The electrode column must be strictly perpendicular to the ground lever. Oblique column is not allowed during operation.

The holder must be placed between the two safety marks on the top electrode, otherwise the column may be broken.

Generally, different manufacturers may make their electrodes with different raw materials and processes, therefore the physical and chemical properties of their electrodes are usually different. Please do not fit electrodes and nipples made by different manufacturers together.

Applications

Industrial Silicon Producing Graphite Electrodes UHP with Nipples

Electrodes in electric arc furnace and ladle refining furnace for steel making;

Electrodes in electric smelting furnace for producing industrial silicon, yellow phosphorus, corundum and so on.

- Q: How to solve the problem of graphite electrode being crushed during electrolysis

- This graphite electrode is so true because it causes gas to expand and disintegrateTantalum electrodes can be solved and not expensive

- Q: Will the concentration of electrolytic sodium sulfite be increased with graphite as electrode?

- No, sodium sulfite reacts with the oxygen produced.

- Q: Can graphite be used as an electrode for electrolysis of silver in silver nitrate?

- Xiaoyi Liyang said the principle is correct, but can get silver? I think we can solve the problem if we take proper measures to get the silver elements, such as separating the anode and the cathode from the salt water!

- Q: Classification of graphite electrodes

- Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q: Why is graphite a negative pole and copper is an anode?

- Electrolysis (Electrolysis) is the current through the electrolyte solution or molten electrolyte (also called electrolyte), caused by the redox reaction in the cathode and the anode, the electrochemical cell can occur when an external DC voltage in the electrolysis process.

- Q: What are the factors that affect the electrode wear rate of machine tools?

- In the pulse peak voltage, current and pulse width decreased, the electrode loss increase, and the heat produced from the processing of large pulse width, is conducive to the adsorption of copper electrode graphitization induced by carbon, which is commonly referred to as the covering effect".

- Q: After vacuum melting of quartz crucible, there are three graphite electrode rods. What's the adjustment?

- The shorter one is the farther away from the other, and the shorter one is the shorter one

- Q: What is anodized graphite?

- Anodized graphite is mainly used for making brushes. The utility model has the advantages of good performance, high resistance coefficient and contact voltage, favorable for suppressing spark, and wide application range, and can be used for various types of motors and motors with more difficult commutation conditions.

- Q: Excuse me, why does the graphite electrode flake when electrolyzed salt water is used?

- For example, according to connection of the electrode, which can be divided into two types of unipolar and bipolar type electrolyzer (see photo). The electrode is connected with the DC power supply parallel polarity monopolar electrolyzer, electrodes on both sides of the same, at the same time as anode or cathode. At the same time as the positive and negative electrode bipolar type electrolyzer ends respectively with DC power supply connected, as anode or cathode. The current through the electrode through the electrolysis cell in series, each side of the intermediate electrode as the anode, the other side is the cathode, so it has a bipolar electrode. When the total area at the same time, the current bipolar type electrolyzer is small, high voltage DC power supply, the required investment ratio monopolar, bipolar type filter press used. The general structure, more compact. But easy to leakage and short circuit, slot structure and operation management is more complex than the monopolar type. The monopolar electrolyzer section is generally rectangular or square, cylindrical covers a large, empty The utilization rate is low and the adoption rate is less

- Q: How do graphitized electrodes differentiate between high power and low power?

- In electrolysis industry, using graphite anode plate as the anode has a history of more than 100 years, the metal anode is in recent decades, the research and application of metal anode in China late last century, only in 70s the technology related to the research and experiment of metal anode, anode on electrolysis industry, mainly through the silver (2%) (0.5%): low silver lead silver alloy, lead and silver tin antimony alloy, lead calcium alloy and lead silver alloy adding nucleating agents and several stages.

Send your message to us

3D Printing Graphite Electrodes for Industrial Silicon Production - UHP with Nipples

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches