Hydraulic Filament Winding Machine Vessel Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 32 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydraulic Filament Winding Machine Vessel Machine

Product Description:

This is special equipment that can produce small-size FRP pipes and tanks, it has been matched the mould-unloading machine and forming set, its main properties are below:

1.The maxi diameter can be wound: DN10000mm

2. The maxi length can be wound: 12000mm

3. The total power:7.5kw

4. The maxi width of roving sheet:150mm.

Product Features:

1. With high automation in the international. It can save approximately 40% of the worker cost.

2. With high production speed and it is easy to operate. It can increase 50% in production efficiency.

3.Using advanced production process- four dimension. The cost of raw material reduce 30% than traditional production process.

Product Parameter:

Name | Hydraulic Filament Winding Machine Vessel Machine |

Brand | CMAX |

Weight | 9.6T |

Dimension(L*W*H) | Customized |

Power | 7.5KW |

Voltage | 220V/420V |

Product Type | FRP Machinery |

Certification | ISO9001:2008 |

Application | Profile |

Raw material | Fiber Reinforced Plastic |

Place of Origin | Guangdong, China (Mainland) |

Color | Selectable |

Warranty | 18months |

Time of Delivery | 30-45 days |

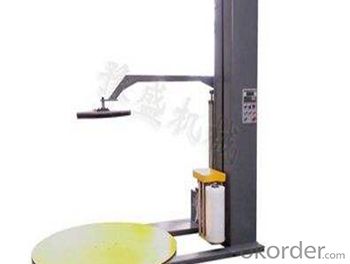

Product Pictures:

Our Services:

1.Researches and development team by knowing the importance of the FRP usage in industry and construction,have successfully conducting different researches and studies projects. At the present , it has several government-supported projects available .

2.Design and engineering services has been given idea from customers, and make out the things you imaged.

3.Istallation and construction team is experienced with installation, commissioning and training service at customer’s factory. In this way, the customer is able to handle management of equipment themselves soon.

4.Technical support is the most importance in production. As long as FRP developing, new and advanced process, material, equipment appeared.

FAQ:

Q1:How Can I Get A Sample?

A1:You can get samples by communicate with our export sales.

Q2:How Long Is Delivery?

A2:Delivery time will be 30-45days according to order quantity.

Q3:What Is The MOQ?

A3:MOQ depends on different items.

- Q: What kind of equipment does the plastic bottle crush processing plant need?

- Would you like to crush the plastic bottle? That crusher, crushing, but also processing it? Besides, I have friends who sell machines. If you need this kind of equipment, I hope I can help you.

- Q: How many venues will it take? How much does it cost?That's what recycling plastic bottles break. Sell again.What's the machine and how much does it cost? What should be done after breaking? If you make a semi-finished product, you can't sell it wellIs there any profit on this line?

- Small production equipment price corresponding -300 HuaSu Fei Yang machine,I was prepared to PET mineral water bottles by color sorting (bottle, cover ring, trademark, water drop), production processes: sorting - crushing (grinding) - Cleaning - drying - bagging, processing in such a manner as to sell 7! No difference, the corresponding price and production equipment prices are 10000 yuan distinction, processed products sold to the product factory, --1PET mineral water bottles, broken pieces (crushed) and PP material broken fragments (crushed) can be done with the same machine!

- Q: What are the methods of forming plastic products introduced in this course?

- Commonly used molding methods have the following1, rolling formingCalendering is often used in thermoplastics. It is used to deliver plastic to a number of parallel, counter rotating hot rollers, which are rolled over many times2, tape castingCasting with dry plastic. It is soluble in the solvent of plastic, due to weight andspread to continuous operation of the metal belt, become thin layer of uniform thickness, then heating apparatus soft volatile agent, curing products, production of film or sheet.3, extrusion moldingExtrusion molding is often used in thermoplastics. This is a melt plasticized plastic which is extruded from the die cavity of the die at the head of the extruder and forms a profile similar to that of the die. It produces plates, pipes, bars, wires, profiles and so on

- Q: What are the plastic products stocks?

- Provide land, property, equipment, vehicle rental services.TS: domestic major enterprises to focus Plitt production of automotive modified plastics products, key high-tech enterprise of national torch plan. Currently has five series of more than 300 varieties, with an annual output of 50 thousand tons of production capacity, production of automotive modified plastics in the domestic enterprises in the top, the yield of modified ABS, PC/ABS alloy products ranked first, the yield of modified PP products are also in the forefront. The company provides services for automobile manufacturing, household appliances, electronic information and other enterprises, specializing in high performance plastic composite materials research, production, sales and service, is one of the industry earlier for the automotive industry the most complete enterprise qualification.

- Q: What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q: I found that the plastic bags and food bags used in the county town of my work are from abroad. I would like to open a plastic bag processing plant. What kind of machines do I need?. How much is it (cheaper, smaller per day)?. Where does the raw material go in?. The main market for vegetables; small bags for small food. Who will answer in detail?. Thank you

- Recommended Xiangxi inspection, old plastic easy to do, but have no production, proposed to do environmental protection cloth generation.

- Q: What plastic products can ABS be used for?

- 4. office equipment ABS has excellent impact resistance, good dimensional stability and rigidity. Forming, housing for manufacturing all kinds of office equipment, economic and practical. Such as fax machines, photocopiers, typewriters and computer monitors and other office equipment. The higher requirement on the fire, so usually are made of flame retardant ABS grade manufacturing.5. die model because ABS plastic machining performance, light weight, low price, in recent years has been widely used to mold model making industry, automobile, electronic appliances, machinery and equipment testing instrument. The rapid forming machine model Dimension is currently the world's most advanced ABS manufacturing standard stereo prototype as raw materials, then you can test of new product appearance, suitable degree and related functions. With the best price in similar products.

- Q: Want to buy an injection molding machine to do some plastic products, equipment about how much money ah? What needs to be prepared?

- More than 100 thousand injection molding, about 10-15, model brand difference, tens of thousands of price difference. In addition, supporting facilities, air pump, cooling tower, burr machine and so on nearly 100 thousand, but also procurement of raw materials costs, site costs, pre operation, investment, etc.. If the injection function is installment, then about 250 thousand can start production.

- Q: What kind of machine is needed for the production of plastic products?

- Seventy thousand or eighty thousand an injection molding machine, a crushing machine, a drying machine forty thousand or fifty thousand, workshop, rent, labor, water and electricity to ten thousand months Duoliangwanyi, mold materials, another operator, of course cost large scale is low.

- Q: What kind of equipment does the groove on the PP plastic board work on?

- It can be machined with a shaper or engraving machine

Send your message to us

Hydraulic Filament Winding Machine Vessel Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 32 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords