HPA Geocells for Slope Stabilization with CE Certificate for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 85800 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

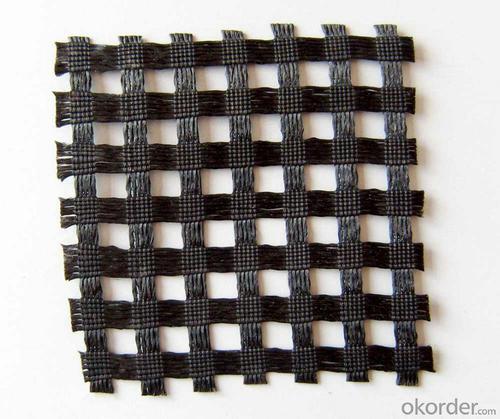

The Description of Geogrid for slope stabilization

Geogrid for slope stabilization is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

The details of Geogrid for slope stabilization

| Type: | Geogrid | Material: | geogrid for slope stabilization | Place of Origin: | China (Mainland) |

| Certificates: | CE,ISO | Color : | White & Black | Width : | 1m--6m |

| Length | 50-200m | Mesh Size: | 10-40mm | Tensile Strength | 30KN-300KN |

| Area Weight | 130-900g/sm | Package | PP bags or PE film | Approximate mesh size | 12.7*12.7 25*25 40*40 |

Packaging & Delivery

| Packaging Details | PP bags or PE film. Or Packed as customers' requests; |

| Delivery Detail | 10-20days after see the payment. |

Remarks: we are very large fortune 500 enterprise with more than 20branches in worldwide, and have almost ten years export experience in geosynthetic field. We have kunlun bank account and have many Iran geosynthetics customers.So if any question or support, please just feel free to contact me at any time.

- Q: Geogrid standard geogrid price geogrid role

- plastic geogridThe plastic geogrid is a kind of polymer material with square or rectangular shape which is formed by stretching, and it can be used as two kinds of uniaxial tension and biaxial tension. The utility model is punched on the extruded polymer plate (raw material is polypropylene or high-density polyethylene), and then directionally stretched under the heating condition. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length. As the polymer in the manufacture of plastic polymer in the process of heating with the extension of the process of re orientation, strengthen the link between the molecular chain force, to achieve the purpose of improving its strength. Its elongation rate is only 10% ~ ~ of the original plate of 15%. If the carbon black and other anti-aging materials are added in the geogrid, the utility model has the advantages of good acid resistance, alkali resistance, corrosion resistance, aging resistance and the like. The bidirectional geogrid two-way geogrid is made of high molecular polymer through extrusion, plate forming, punching process and then longitudinal and transverse stretching. The material has great tensile strength in both longitudinal and transverse directions, the chain system of this structure in the soil can also provide a more effective force to bear and spread of the ideal, to adapt to the foundation of unidirectional geogrids uniaxial geogrid in the large area of a permanent load is a polymer by extrusion pressure a thin plate and punching network rules, and then the longitudinal stretch. This process make the linear polymer into a state of orientation and form long oval mesh structure integrity and uniform distribution of nodes with high intensity. The structure has very high tensile strength and tensile modulus,.

- Q: Can geogrids be used in mining operations?

- Yes, geogrids can be used in mining operations. Geogrids are commonly used in mining for various purposes such as soil stabilization, reinforcement of embankments, and slope stabilization. They provide strength and stability to the mining site, preventing soil erosion and enhancing safety during mining operations.

- Q: Can geogrids be used in reinforcement of mechanically stabilized slopes?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized slopes. Geogrids are commonly used in such applications to enhance the stability and strength of slopes by providing additional tensile strength and confinement to the soil. This helps to resist lateral forces and prevent slope failures, making geogrids an effective solution for reinforcing mechanically stabilized slopes.

- Q: How do geogrids improve the performance of retaining walls?

- Geogrids improve the performance of retaining walls by providing tensile strength and reinforcement to the soil, thereby increasing the stability and load-bearing capacity of the wall. They prevent soil erosion and lateral movement, reducing the risk of wall failure. Additionally, geogrids distribute the applied loads more uniformly, minimizing differential settlement and reducing the overall stress on the retaining wall structure.

- Q: Asked the retaining wall engineering grille mistook polypropylene as high density polyethylene, how to do? Is there any remedy?

- What is wrong with the polypropylene in the geogrid in the retaining wall of the road? Performance will not be affected? Is there any remedy?

- Q: Who knows the laying method of geogrid?

- Geogrid price Description: now all over the country, many manufacturers of geogrid, product prices vary, the price of raw materials and the impact of regional differences,

- Q: How do geogrids help with slope stabilization?

- Geogrids help with slope stabilization by providing tensile reinforcement to the soil, increasing its overall strength and stability. The geogrids are placed within the soil layers and act as a support system, preventing soil erosion and reducing the risk of slope failure or collapse.

- Q: What is the effect of creep rupture on geogrid performance?

- The effect of creep rupture on geogrid performance is detrimental as it leads to a significant decrease in the geogrid's strength and stability over time. Creep rupture refers to the gradual elongation or deformation of a material under constant load, which can eventually result in the geogrid failing and losing its ability to provide reinforcement or confinement. This can compromise the overall integrity and effectiveness of the geogrid in various civil engineering applications, such as soil stabilization, slope reinforcement, or retaining wall construction. Therefore, managing and minimizing creep rupture is crucial to maintaining the long-term performance and durability of geogrids.

- Q: What are the long-term maintenance requirements for geogrids?

- The long-term maintenance requirements for geogrids are typically minimal. Once installed properly, geogrids generally do not require any specific maintenance. However, regular inspections are recommended to ensure that the geogrids are functioning as intended and to identify any potential damage or deterioration. In case any issues are detected, prompt repairs or replacements should be carried out to maintain the effectiveness of the geogrids over time.

- Q: Classification of plastic geogrid

- Three, the application of one-way plastic geogrid:Unidirectional plastic geogrid is a kind of high strength geosynthetics. Widely used in dams, tunnels, docks, highways, railways, construction and other fields.Three, one-way plastic geogrid its main purposes are as follows:1 strengthen the roadbed, can effectively distribute the diffusion load, improve the stability and bearing capacity of the roadbed, prolong the service life;2 can withstand greater alternating load;3 to prevent the roadbed material loss caused by roadbed deformation, cracking, one-way plastic geogrid4 to make the retaining wall after the filling capacity, reduce the earth pressure of retaining wall, save cost, prolong service life, and reduce maintenance costs;5 combined with spraying anchor concrete construction method for slope maintenance, not only can save 30% - 50% investment, but also can shorten the construction period more than doubled;6 in the roadbed and surface of the road to join the geogrid, can reduce the deflection, reduce the rut, the delay time of 3 to 9 times, can reduce the structure layer thickness of up to 36%;7 applies to all kinds of soil, no need to draw materials, save time;8 the construction is simple and quick, can greatly reduce the construction cost.

Send your message to us

HPA Geocells for Slope Stabilization with CE Certificate for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 85800 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords