Hp 450 Graphite Electrodes RP HP UHP for Steelmaking Electric Arc Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

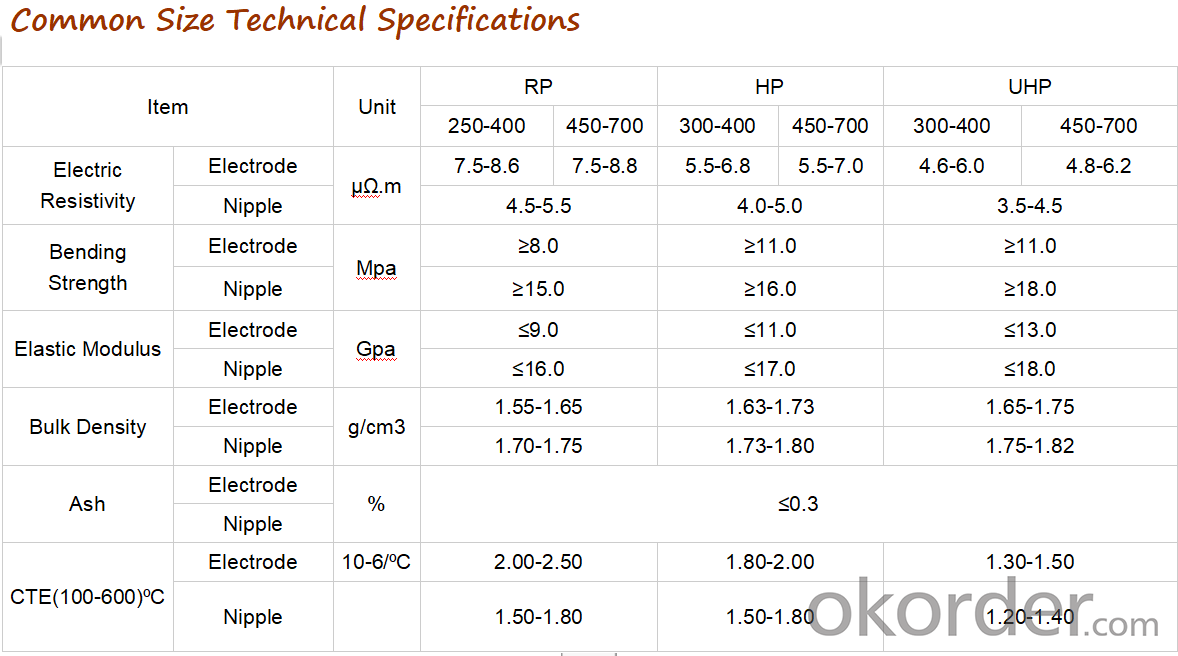

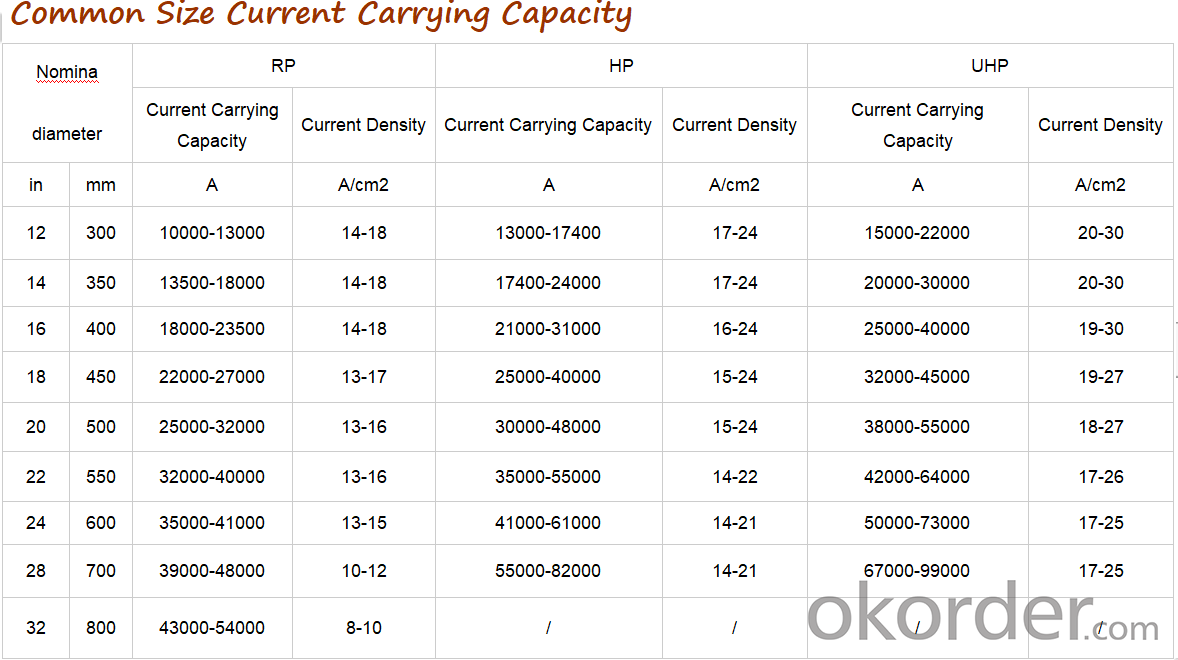

Specification

Graphite Electrode

Product range:

•RP: 200-700mm

•HP: 200-750mm

•SHP: 200-750mm

•UHP: 350-750mm

Quality control:

•Raw material:

Needle coke from world famous brand like Mitsubishi, Mizushima, Phillips 66 etc. and Chinese Tier-One manufacturers.

•During Production:

1.Visual automatic batching control room, 10 sets of high-precision machining equipment,

and an investment of 70 million on-line dust removal and environmental protection equipment,

exhaust gas recycle equipment.

2.High dimensional accuracy of nipples and threads.

3.Professional technical team with decades of experiences.

4.Before shipment, each electrode is inspected, test report will be made and has traceability mechanism.

•Logistics: High-standard shipping packaging to prevent bumps, take photos/videos for file.

•After-sales:

If there are quality problems with our products, we will replace them or solve them on-site according to the situation.

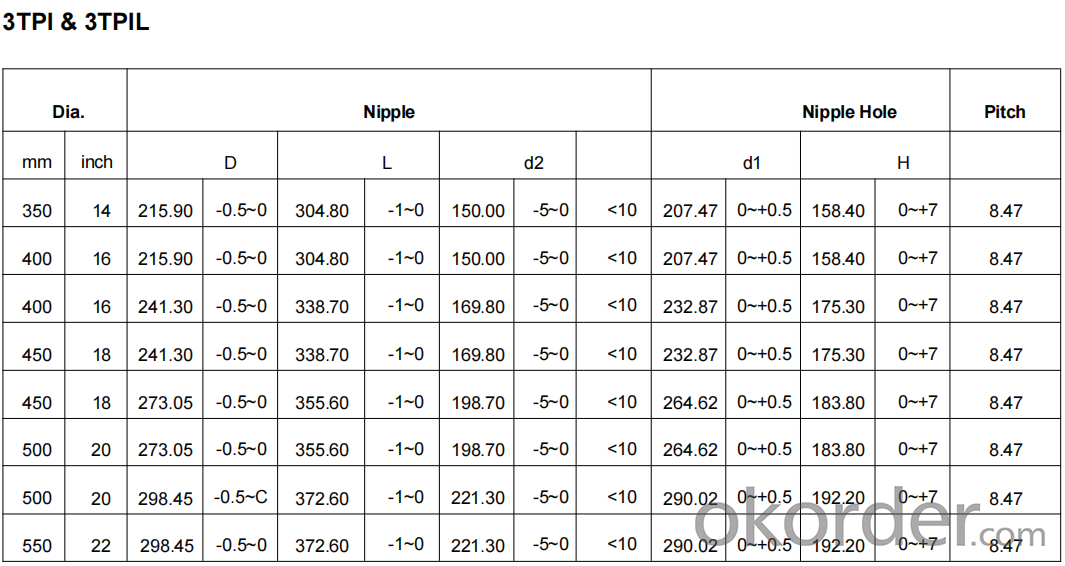

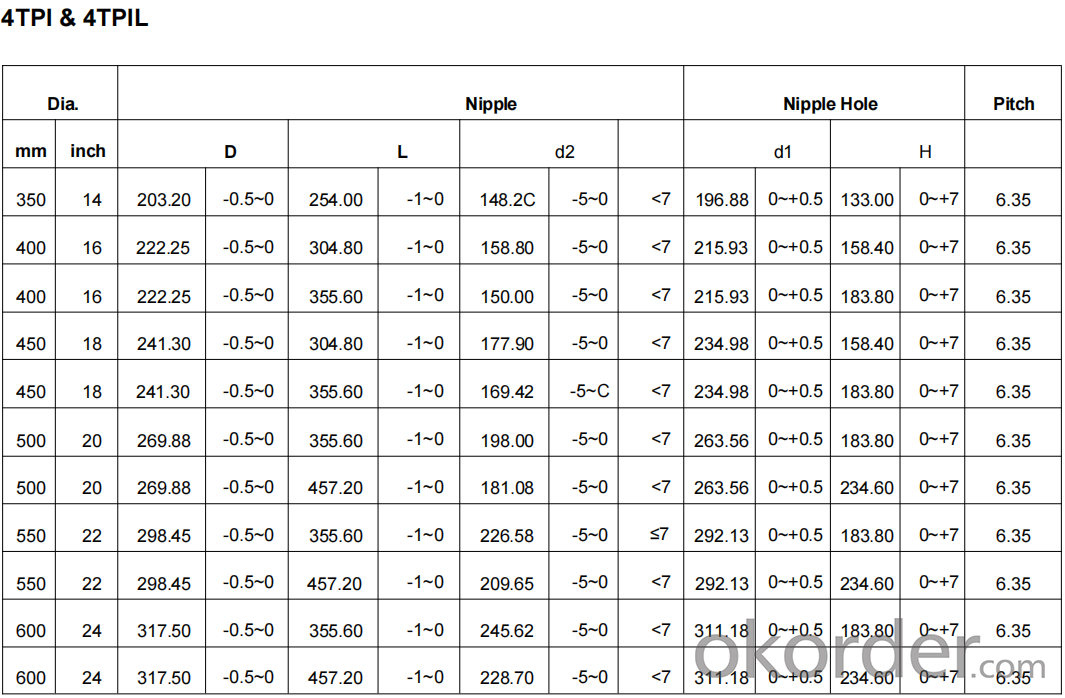

Please consult us for details of other dimensions.

Please consult us for details of other data.

Please consult us for details of other data.

- Q: The future of graphene

- Field of semiconductor materials. Graphene is considered to be an ideal material for replacing silicon. A large number of powerful enterprises have developed graphene semiconductor devices. The Han Guocheng Institute has developed a highly stable n type graphene semiconductor that can be exposed to air for a long time. Graphene silicon optoelectronic hybrid chip developed by Columbia University has broad application prospects in optical interconnection and low power photonic integrated circuit. IBM researchers have developed graphene field effect transistors with cutoff frequencies of up to 100GHz, with frequency performance far superior to the cut-off frequency of the most advanced silicon transistors of the same gate length.

- Q: The use of graphite as an electrode in alumina electrolysis

- Graphite acts as an electrode:The electrical conductivity of graphite, the electrode itself must be electrically conductive;When graphite acts as an anode, it acts as a reducing agent and displaces an element of aluminum in a chemical reaction;Graphite is cheap and cost saving.

- Q: Graphite electrode in milling machine processing, dust is especially big, boot 5 minutes, workshop can not open the figure, what is the solution?

- Because will cause a short circuit, the best selection of bag type dust collector, our company is graphite in Linzhou, and before you like, then Xinxiang Keli machinery to help us to design a set of dust removal equipment, and then the operation almost no dust, you can consult the specific

- Q: The difference between graphite electrode and graphite rod

- The two materials are different.Graphite electrode is mainly in the petroleum coke and needle coke, coal tar pitch as binder, calcination, mixing, kneading, pressing, baking and graphitization, and made the processing machine, is a conductor in an electric arc furnace to form arc release electricity for heating and melting of the charge, according to the quality index level, can is divided into ordinary power, high power and ultra high power.

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The impact of carbon on the car is quite large, first of all, to reduce the power of the engine, that is, to make the power output uneven and gradually attenuated, in other words, more and more lack of force. Two is to increase fuel consumption, increase your financial burden.

- Q: Are graphite and carbon electrodes the same? What kinds of ore furnaces are used?

- The main components of carbon electrodes are graphite, carbon powder and other impurities which are not converted into graphite. The resistivity is higher than that of graphite electrode. These electrodes are mostly used in electric furnace steelmaking, smelting aluminium oxide and other electric arc furnaces.

- Q: Please senior doubts. The graphite electrode is used in the mold cavity In what case is graphite processing taken?

- Instead of copper as discharge material.1. Electrode design1 can reduce the number of individual electrodes / can be made into a composite electrode2, it can save the electrode clamp system and save the cost2, the electrode processing1, high speed milling rough processing copper block 3 times2, high-speed milling finishing faster than copper 5 times3. Good machinability4, complex geometric modeling can be realized3, light weight, its density is less than 1/4 of copper1, good thermal stability (without deformation)2 can reduce the number of individual electrodes / can be made into a composite electrode3, without deburring4. The electrode is easy to clamp4 、 electric discharge machining EDM1, roughing, the electrode loss is small2, high work removal rate3 can reduce the number of individual electrodes / can be made into a composite electrode4. No pollution to the environment in the electrolyte5, light weight, its density is less than 1/4 of copper6, excellent thermal stability, the electrode does not change7, the fine graphite electrode can be used to produce high quality workpiece surfaceDifferent grades of graphite materials can be used for processing different workpieces

- Q: Classification of graphite electrodes

- Allows the use of current density of less than 17A/ cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, yellow phosphorus and other ordinary power furnace.

- Q: What is anodized graphite?

- According to the production method of brush, there are two kinds. One is colored brush, that is, metal graphite brush. One is black brush. The black brush is made of petroleum coke, pitch coke, carbon black, charcoal and natural graphite powder and so on. Some binders (such as coal tar pitch, coal tar and artificial resin etc.) are added to the black brush. The resin binder by curing brush manufactured for high resistance brush, and the calcined product called carbon brush and graphite brush (with natural graphite as the main raw material) graphitised after product called electrographite brush,

- Q: What is the difference between SGL graphite electrode and graphite electrode in general?

- In fact, the graphite electrode abroad (including Japan) in several ways than we can control the fine, one is pure, another is anisotropic (resistance, thermal conductivity ah) usually do some control, in the strength of domestic now is also doing well, but when we are comparing high quality products, general domestic products it is basically a piece of the indicators are poor

Send your message to us

Hp 450 Graphite Electrodes RP HP UHP for Steelmaking Electric Arc Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches