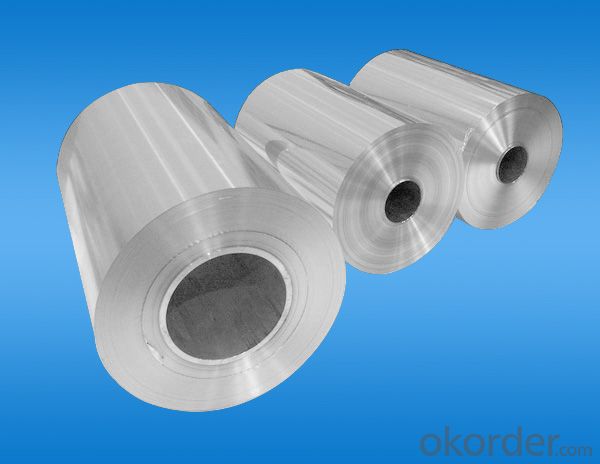

Aluminum Sheets 3x3 - Household Aluminium Foil Jumbo Roll from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

colorful aluminium foil for medicine bottle caps

1.alloy 8011 h14

2.thickness 0.17-0.21mm

3.used aluminium vial seals

Lacquered aluminium strip for pharmaceutical caps | |

Alloy | 8011 |

Temper | H14 & h16 |

Thickness | 0.17-0.21mm |

Width | 30-800mm |

Earing | 2% max |

ID | 76mm and 152mm |

Tensile st | 135-155mpa |

eongation | 2.5-4% |

Surface Treatement |

|

Test item | Autoclave resistance , aceton test. Hgcl2 . Rigid test ect |

Application | Pharmaceutical caps . Vial seals ect |

MOQ | 3-5ton per size |

Packaging | Wooden stronger boxes |

Shipment | 25-30days after order and deposit |

Payment | TT or lc at sight |

CNBM is professional coating manufactuer and supply. We gurantee goods quality and very good service! | |

- Q: What are the maximum dimensions available for aluminum sheets?

- The maximum dimensions available for aluminum sheets depend on various factors such as the manufacturing process, supplier capabilities, and customer requirements. However, standard aluminum sheet sizes typically range from 0.02 inches (0.5 mm) to 0.25 inches (6.35 mm) in thickness, and widths can vary from 24 inches (609.6 mm) to 72 inches (1828.8 mm). The length of aluminum sheets can generally reach up to 144 inches (3657.6 mm). It is important to note that these dimensions may vary depending on the specific supplier or manufacturer, and custom sizes can be produced based on individual needs.

- Q: Can aluminum sheets be used for electrical wiring?

- No, aluminum sheets cannot be used for electrical wiring. While aluminum is a good conductor of electricity, it is not suitable for electrical wiring due to its high electrical resistance. Copper is the preferred material for electrical wiring as it has low resistance and is more efficient in conducting electricity. Additionally, aluminum is prone to oxidation, which can lead to poor conductivity and potential fire hazards. Copper wires are specifically designed and manufactured to meet the electrical safety standards, ensuring reliable and safe electrical connections.

- Q: Can aluminum sheets be coated with protective films?

- Yes, aluminum sheets can be coated with protective films.

- Q: Hi I am getting a laptop pretty soon and have pretty much decided on a Mac. But really a white macbook is $1150, and aluminum is $1400. And just so no one says this, the white one is updated with all the same hardware(Advanced graphics, etc.) I want to get it asap so the $250 would mean about 2 months longer which would kind of be a drag. I also understand the aluminum doesn't have a firewire port, but idk what the hell that even is so can someone explain what it is and why I would care about it. Basically, is it worth the 2 months and $250 for the aluminum. Thanks.

- There is no difference between the plastic/aluminum on the inside at all except for the firewire port, and some of the aesthetic differences (the aluminum one just looks cooler in my opinion, the lcd is behind the glass panel, the trackpad is made of glass too, and the battery meter is on the side, not underneath like the white macbook). Firewire is IEEE 1394, it's like USB but not used as much except with high-speed external hard drives and digital video cameras (which can be used with video editing software on Macs). It is faster than USB.

- Q: This question asks about the key factors to consider when buying aluminum sheets, including material properties, thickness, surface finish, and other relevant details.

- <p>When purchasing aluminum sheets, consider the following specifications: 1) Alloy type, which determines properties like strength and corrosion resistance; 2) Thickness, measured in millimeters, affecting the sheet's durability and application; 3) Width and length, which should match your project requirements; 4) Surface finish, such as mill finish, anodized, or painted, which impacts aesthetics and protection; 5) Temper, indicating the hardness and formability of the sheet; 6) Certifications, ensuring the sheet meets industry standards; 7) Supplier reputation and customer reviews for quality assurance. These factors will help you select the right aluminum sheet for your specific needs.</p>

- Q: Are aluminum sheets suitable for hydraulic applications?

- Yes, aluminum sheets are suitable for hydraulic applications. Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and high thermal conductivity, making it a suitable material for hydraulic systems. It is commonly used in the construction of hydraulic tanks, cylinders, and other components due to its durability and ability to withstand high pressure and fluid flow.

- Q: Can aluminum sheets be polished for a mirror-like finish?

- Yes, aluminum sheets can be polished to achieve a mirror-like finish.

- Q: How do you prevent oil or grease stains on aluminum sheets?

- To prevent oil or grease stains on aluminum sheets, there are a few measures you can take: 1. Clean the aluminum sheets regularly: Regularly cleaning the aluminum sheets will help remove any existing oil or grease stains and prevent them from accumulating. Use a mild detergent or a mixture of water and vinegar to clean the sheets. Avoid using abrasive cleaners or scrubbing pads as they may damage the surface. 2. Apply a protective coating: Applying a protective coating can act as a barrier between the aluminum surface and oil or grease. There are various coating options available, such as clear lacquer or anodizing. These coatings create a smooth and non-porous surface, making it harder for oil or grease to penetrate and stain the aluminum sheets. 3. Use a barrier material: If you frequently work with oil or grease near aluminum sheets, consider using a barrier material to prevent direct contact. This could include using a silicone mat or placing a layer of parchment paper or aluminum foil between the aluminum sheet and the oil or grease source. 4. Store aluminum sheets properly: Proper storage is essential to prevent oil or grease stains on aluminum sheets. Make sure to store them in a clean and dry environment, away from any potential sources of contamination. Keep the sheets covered or wrapped in a protective material to prevent dust, dirt, or oil from settling on the surface. 5. Handle aluminum sheets with clean hands: When handling aluminum sheets, ensure your hands are clean and free of oil or grease. Even small amounts of oil or grease on your hands can transfer onto the sheets and cause stains. If necessary, wear clean gloves or use clean tools when working with aluminum sheets to minimize the risk of stains. By implementing these preventive measures, you can significantly reduce the chances of oil or grease stains on your aluminum sheets, keeping them clean and in good condition.

- Q: i keep hearing all these things about burning aluminum foil and such

- Yes, it will not hold up and if the fire gets hot enough, it may melt. It is better to use rocks that do not come from a stream or any water area.

Send your message to us

Aluminum Sheets 3x3 - Household Aluminium Foil Jumbo Roll from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords