Hot Selling Deformed Reinforcing Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

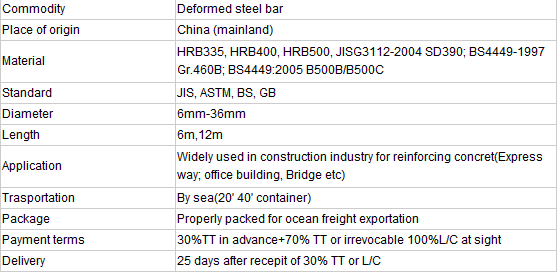

Specifications

Grade HRB335-2007 HRB400-2007 HRB500-2007

Quenched or microalloyed

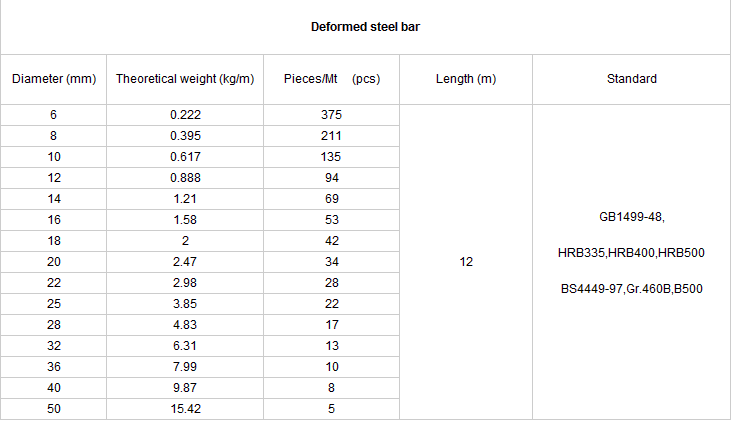

DIA 12.0mm~40.0mm deformed bar

STEEL REBARS

GB1499 Grade HRB335-2007 ( quenched or microalloyed)

GB1499 Grade HRB400-2007 (quenched or microalloyed)

GB1499 Grade HRB500-2007 ( microalloyed 20MnSiNb and 20MnSiTi)

Cutting to length: 9 or 12 1500-5000(KG) (Max.500kg/m)

Cutting to length: 6 or 7 or 8 1500-4000(KG) (Max.500kg/m)

- Q: What is the effect of steel rebars on the thermal conductivity of concrete?

- The effect of steel rebars on the thermal conductivity of concrete is generally negligible. While steel has a higher thermal conductivity than concrete, the relatively low volume fraction of rebars in typical reinforced concrete structures does not significantly impact the overall thermal conductivity of the material.

- Q: Are there any standards or codes for steel rebars?

- Certainly, steel rebars are subject to standards and codes that are essential for guaranteeing their quality, safety, and compatibility across various construction projects. One of the most widely recognized standards for steel rebars is the ASTM A615/A615M, which is responsible for specifying the requirements of deformed and plain carbon-steel bars used in concrete reinforcement. This standard covers a range of physical and mechanical properties, including chemical composition, yield strength, tensile strength, elongation, and bendability. It also provides guidelines for marking, packaging, and testing of rebars. In addition to the ASTM A615/A615M, there are other relevant standards and codes utilized in different countries and regions. For instance, in Europe, the European Standard EN 10080 outlines the specifications for steel rebars, including dimensions, tolerances, and mechanical properties. Similarly, the British Standard BS 4449 is widely employed in the United Kingdom for steel reinforcement in concrete. These standards and codes play a pivotal role not only in ensuring consistency during the manufacturing and production of steel rebars but also in aiding architects, engineers, and construction professionals in selecting the most suitable rebars for their projects. Compliance with these standards is of utmost importance to ensure the structural integrity, durability, and safety of reinforced concrete structures. It is imperative for stakeholders in the construction industry to acquaint themselves with the pertinent standards and codes for steel rebars and consistently adhere to them. This practice helps to uphold high-quality construction protocols and mitigate the risk of failures or accidents caused by substandard materials.

- Q: What's the difference between primary and two grade steel and three grade steel?

- The two is the performance of classification (class), for example, China's current implementation of standards, (G B1499.2-2007) for steel wire for 1499.1-2008), according to the strength (tensile strength yield point / steel) will be divided into 3 levels; the Japanese industrial standard (JI SG3112), according to the comprehensive performance of the steel branch for the 5 species; the British Standard (BS4461), also provides some level of performance test of thread steel. In addition, the thread steel can be classified according to the use, such as reinforced concrete, ordinary steel bars and reinforced concrete bars for heat treatment.

- Q: Can steel rebars be spliced or joined together on-site?

- Yes, steel rebars can be spliced or joined together on-site. This process involves connecting two rebars using various techniques such as overlapping, welding, mechanical couplers, or lap splicing. The method chosen depends on the specific project requirements, strength considerations, and local building codes.

- Q: Do steel rebars have any impact on the fire resistance of a structure?

- Yes, steel rebars have a significant impact on the fire resistance of a structure. The use of steel rebars in reinforced concrete provides additional strength and stability to the structure, especially during a fire. Due to their high melting point and heat transfer resistance, steel rebars help to maintain the structural integrity of the building for a longer period of time, allowing occupants to evacuate safely and giving firefighters more time to control the fire.

- Q: What are the guidelines for proper spacing and arrangement of steel rebars in concrete structures?

- Proper spacing and arrangement of steel rebars in concrete structures play a vital role in maintaining the structural integrity and strength of the final construction. Below are some key guidelines to consider: 1. Reinforcement Bar Spacing: The spacing between rebars is determined by the structural engineer, taking into account the intended load and design requirements. It is generally advisable to maintain a minimum spacing of three times the bar diameter. This spacing helps ensure sufficient concrete cover, providing protection against corrosion and enhancing fire resistance. 2. Bar Diameter and Grade: The selection of bar diameter and grade should be based on the structural demands and engineer's specifications. Common bar diameters range from 6mm to 50mm, with higher diameters used for heavy-duty construction. To meet the desired tensile strength and ductility, the steel grade should adhere to specified standards such as ASTM or BS. 3. Bar Placement and Alignment: Rebars should be accurately placed and aligned according to the structural drawings and specifications. They should be adequately supported to maintain their position during concrete placement. To ensure appropriate concrete cover, it is necessary to maintain a suitable clearance between the bars and the formwork, typically around 25mm to 50mm. 4. Splicing and Overlapping: When the required reinforcement length exceeds the available bar length, splicing or overlapping of bars becomes necessary. The splicing method should comply with the engineer's specifications and be performed using appropriate techniques like welding, mechanical couplers, or lap splices. Overlapping should be done as per the specified length, ensuring sufficient overlap to maintain continuity and structural integrity. 5. Reinforcement Around Openings: Special attention should be given to reinforcement around openings such as doorways, windows, and penetrations. Additional reinforcement bars, such as lintels or beams, may be required to distribute the load and prevent cracking or structural issues in these vulnerable areas. 6. Clear Cover: The clear cover refers to the distance between the concrete surface and the outer surface of the reinforcement bars. It is crucial for protecting the steel against corrosion, fire, and other environmental factors. The clear cover should be maintained as specified in the design drawings, typically ranging from 25mm to 75mm, depending on the structural requirements and exposure conditions. It is important to note that these guidelines may vary depending on specific project requirements, local building codes, and the recommendations of the structural engineer. Therefore, it is essential to consult and adhere to approved design documents and engage experienced professionals to ensure proper spacing and arrangement of steel rebars in concrete structures.

- Q: What are the different types of steel rebars used in marine construction?

- In marine construction projects, various types of steel rebars are utilized to withstand the harsh conditions and corrosive environments commonly found in marine structures. 1. Stainless Steel Rebars: These rebars, containing chromium and nickel, are crafted from high-grade stainless steel. They exhibit exceptional resistance to corrosion, making them ideal for marine construction projects where exposure to saltwater and other corrosive elements is anticipated. Though more expensive, stainless steel rebars offer superior durability and longevity. 2. Epoxy-Coated Rebars: Carbon steel rebars are coated with an epoxy layer, acting as a protective barrier against corrosive elements and reducing the risk of rust and corrosion. These rebars are commonly employed in marine construction projects with high saltwater exposure. 3. Galvanized Rebars: By subjecting carbon steel rebars to a hot-dip galvanization process, a layer of zinc is applied, providing excellent corrosion resistance. Galvanized rebars are frequently used in marine construction projects susceptible to seawater or salt spray exposure. 4. Fiberglass Rebars: Composed of high-strength glass fibers embedded in a polymer matrix, fiberglass rebars offer excellent corrosion resistance unaffected by saltwater or other corrosive elements. These rebars are lightweight, non-magnetic, and possess high tensile strength, making them suitable for marine construction projects. 5. Carbon Steel Rebars: Carbon steel rebars are the most commonly used rebars in construction, including marine projects. Although not inherently corrosion-resistant, they can be treated with protective coatings, such as epoxy or galvanization, to enhance their durability and resistance to corrosive environments. It is crucial to consider the specific requirements and conditions of a marine construction project when selecting the appropriate type of steel rebars. Factors such as saltwater exposure, humidity, and anticipated lifespan of the structure should be taken into account to ensure its longevity and safety.

- Q: How do steel rebars perform in fire-resistant constructions?

- Steel rebars perform well in fire-resistant constructions due to their high melting point and thermal conductivity. They can withstand high temperatures for an extended period without significant deformation or loss of strength. This makes them suitable for reinforcing concrete structures in fire-prone areas, providing stability and structural integrity during a fire. Additionally, the thermal conductivity of steel helps to dissipate heat, reducing the risk of localized temperature increases that could compromise the overall fire resistance of the construction.

- Q: Can steel rebars be bent without compromising their strength?

- Steel rebars possess the ability to be bent while still maintaining their strength. Their high tensile strength enables them to endure the forces of bending and stretching without experiencing any breakage or loss of structural integrity. The process of bending involves the application of a regulated amount of force to the rebar, causing the material to deform and acquire a new shape. However, it is essential to adhere to the recommended limits and guidelines provided by the manufacturer or industry standards when carrying out the bending procedure. Exceeding the specified limits may result in the development of microcracks or other defects that can compromise the strength of the rebar. Therefore, it is of utmost importance to employ proper bending techniques and utilize suitable equipment to ensure that the steel rebars retain their strength even after being bent.

- Q: Are steel rebars suitable for use in structures with high resistance to corrosion?

- No, steel rebars are not suitable for use in structures with high resistance to corrosion.

Send your message to us

Hot Selling Deformed Reinforcing Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords