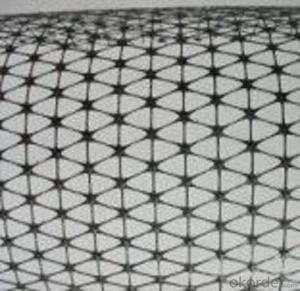

Tensar Geogrids Compatible Hot Sales Geomembrane Hand Welder

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Sales Geomembrane Hand Welder

The description of Geomembrane hand welder:

The control of this series of welding machine adopts PID automatic thermostatic control with high control accuracy and low temperature fluctuation; Speed control adopts PWM automatic voltage and speed regulation circuit, driven by DC servo motor, with great output torque and the operating is stable. It can maintain a constant speed on the condition of creeping, vertical creeping and variable road load. Also this series of welding machine is stable in performance despite of external temperature and voltage variation.

The application of Geomembrane hand welder:

Geomembrane welding machine is our new developed products, which can weld geomembrane of various thickness and are applicable for welding of all thermal-fused material such as LDPE, PVC, HDPE, EVA, PP and the like.

Advantage of Geomembrane hand welder:

This series of welding machine is excellent in performance and easy for operating, with high welding speed and good work quality. It is extensively used in engineering projects such as expressways, tunnels, reservoirs, waterproof of construction and so on

The specification of Geomembrane hand welder:

Voltage (V): 220V

Frequency (Hz): 50Hz

Power (P): 750W

Welding speed (V): 0.5-5m/min

Heating temperature (T): 0-45 Celsius Deg

Thickness of material to be welded: 0.2mm-1.5mm

Overlap width: 100mm

Welding width: 12.5mm× 2, interior cavity 12mm

Seam strength: ≥ 85% base material (tensile resistant in shear direction), complete machine

Weight: 5Kg

Insulation class: Class II

- Q: Can geogrids be used in ground improvement techniques?

- Yes, geogrids can indeed be used in ground improvement techniques. Geogrids are commonly employed to reinforce and stabilize weak soils, providing increased strength and stability to the ground. They are often used in applications such as retaining walls, embankments, and road construction to enhance the load-bearing capacity and prevent soil erosion. By distributing the load more evenly and reducing settlement, geogrids effectively improve the overall performance and longevity of the ground.

- Q: What is the difference between bidirectional geogrid and unidirectional high strength geogrid

- This material is characterized by a very high tensile strength and tensile modulus in the tensile direction, which provides an ideal chain system for soil, and low tensile. It is an ideal reinforcement material at present.

- Q: Are geogrids suitable for reinforcing landfill caps?

- Yes, geogrids are suitable for reinforcing landfill caps. Geogrids are commonly used in landfill engineering to enhance the stability and strength of landfill caps. They provide reinforcement and prevent the movement and erosion of soil, thereby increasing the overall efficiency and effectiveness of landfill caps in containing waste materials.

- Q: What is the typical length of a geogrid roll?

- The typical length of a geogrid roll can vary depending on the manufacturer and application, but it is usually around 50 to 100 meters in length.

- Q: Are geogrids effective in stabilizing dredged material containment areas?

- Yes, geogrids are effective in stabilizing dredged material containment areas. They provide reinforcement and stability to the soil, preventing erosion and maintaining the integrity of the containment area. Geogrids are specifically designed to distribute and manage loads, improving the overall performance and long-term stability of dredged material containment areas.

- Q: How do geogrids improve the stability of railway embankments?

- Geogrids improve the stability of railway embankments by providing reinforcement and preventing soil movement. They distribute the load more evenly, reducing the potential for settlement and slope failure. Additionally, geogrids increase the bearing capacity of the embankment, enhancing its overall stability and longevity.

- Q: Can geogrids be used in soil stabilization for agriculture?

- Yes, geogrids can be used in soil stabilization for agriculture. Geogrids are commonly used to reinforce soil and provide stability to various types of agricultural applications, such as retaining walls, embankments, and roads. They help to prevent soil erosion, improve load-bearing capacity, and enhance overall soil stability, making them an effective solution for soil stabilization in agricultural settings.

- Q: How to effectively control the quality of Geogrid in the process of construction

- 3 when laying geosynthetics, the direction of high strength should be placed in the main stress direction of the embankment.4 geosynthetic materials should be paved after the design requirements of the back section, and timely coverage with sand.5 rolling and transportation equipment, such as rolling or walking directly on geosynthetics.6 the width of the lap and anchor meet the requirements.7 of the original land drainage should be formed 4% of the crown.8 shop geosynthetics are hidden works, the construction process should have the quality control personnel on-site monitoring and do a good job of hidden engineering inspection records, report to the supervisor can be recognized for the next construction process.

- Q: How do geogrids help in reducing construction material consumption?

- Geogrids help in reducing construction material consumption by providing reinforcement to the soil, allowing for the use of thinner layers of construction materials such as asphalt or concrete. This reduces the overall amount of material required for the project, resulting in cost savings and environmental benefits. Additionally, geogrids help distribute loads more evenly, preventing excessive settlement and reducing the need for additional materials to address potential issues.

- Q: What are the typical applications of geogrids?

- Geogrids are commonly used in various civil engineering applications. They are primarily used for soil stabilization, reinforcement, and erosion control in projects such as retaining walls, slopes, embankments, roadways, and pavements. Geogrids help improve the overall strength and stability of these structures by distributing loads, reducing lateral movement of soil, and preventing soil erosion.

Send your message to us

Tensar Geogrids Compatible Hot Sales Geomembrane Hand Welder

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords