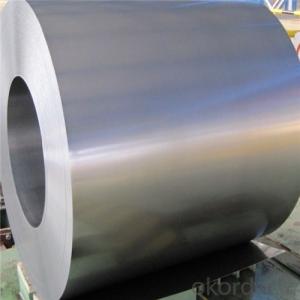

Hot Sale Grade of Stainless Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description.

Surface Treatment:2b/Ba/Polish/No.4/8k

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, AISI

Application:Industrial and House

Edge:Mill

Stock:Not Stock

Steel Grade:201/202/301/304/410/430/409

Raw Material:Bao Steel/Wuhang/Tisco

Width:20-1230mm

Thickness:0.2-2.5mm

Grade:201/202/301/304

Finish:2b/Ba/Polish/8k/6k

Export Markets:Global

Product Description

1. 15 days delivery

2. deep drawing quality

3. High strength

4. Minimal maintenance

5.Technique: Cold rolled

6.Surface treatment: 2B/BA/NO.4/POLISH/8K

7.coil Thickness: 0.22-2.50mm /circle thickness:0.24-0.8mm

8.coil Width: 20-1240mm/ circle diameter:145-560mm

9.Length: To be requirement

10.Edge: Slit edge / mill edge

11.Payment: TT or L/C

12.Packaging Detail: Standard export packing

Note: We can produce for you according to your specification. We can produce other standard as the customers' requirement,

Product advantage:

1. High extensibility, easily welded, hard to rust, the best choice for making decoration pipe.

2. Continuous casting billet produced by refine furnace, no joint, annealed by Continuous bright annealing furnaces,

3. Good quality and reasonable price.

Application: Chemical, petrochemical industry, oil/gas, mechanical, plant engineering and construction

- Q: I'm talking about the sort of carbon fiber that's used in the auto industry (mostly in supercars).If an object made of steel were to be copied by an exact same object, but made of carbon fiber - how lighter would the carbon fiber object be?For example, if a table is made of steel and it weighs X, how much will it weigh if it were made of carbon fiber?Thanks.

- In most applications, you do not want to make the graphite fiber composite object the same size as the steel object. You want it to have the same strength. So... the benefit of using the composite is not just the difference in density. What you really want to compare is the specific strength and you can define this slightly differently depending on your application. As a simple example, suppose you need to hang a weight of 100 pounds from a beam with a bar (so the load is pure tension) and not have the weight permanently stretch the bar (so stress in the bar is less than the yield stress). You can calculate the cross sectional area of steel and compare that to the cross sectional area of the graphite fiber composite required. If your application is more complicated, say it has to support the load and flex up to 10 degrees and survive some impact loading and operate at a max temperature of 200C, then you have more homework to do to select the best material. And... if you are not rich enough so that money is no object, you also need to consider the cost.

- Q: What are they worth today? As well as a 1943 steel nickel?

- The 1943 zinc coated steel cent is very common in circulated grades. They were saved by a lot of people because they are a one year type coin. I can buy them for .02 to .10 each depending on grade. Uncirculated ones are worth more, a few dollars. There is no such thing as a 1943 steel nickel. The nickel that year were made of 56% copper,35% silver and 9% manganese. The 1943 nickel sells for around a $1 in very fine to $2 in extra fine. It is worth more in high grade mint state.

- Q: All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- I like Cerama Bryte. They make several stainless steel cleaning products. I love the Stainless Steel Cleaning Polish Conditioner Wipes. They also make Stainless Steel Appliance Cleaner.

- Q: I am going to be working as a mechanic at my school and I just wanted to know if I should get the steel toe boots or regular. I heard that steel toe boots can be dangerous and uncomfortable. The mechanics recommended getting steel toe to be safe but i'm not sure.

- Get soft toe boots because if something falls on the steel toe boots the metal goes thru the boot and cuts you.

- Q: How are steel coils inspected for chemical composition using spectroscopy?

- Spectroscopy techniques such as X-ray fluorescence (XRF) and laser-induced breakdown spectroscopy (LIBS) can be employed to examine the chemical makeup of steel coils. XRF involves directing an X-ray beam onto the surface of the steel coil, prompting the sample's atoms to emit distinct X-ray fluorescence radiation. By examining the energy and intensity of these emitted X-rays, one can determine the elemental composition of the steel. This method is both rapid and non-destructive, enabling swift and accurate assessment of the steel coil's chemical composition. On the other hand, LIBS entails focusing a laser beam onto the steel coil's surface, generating a high-temperature plasma. The plasma emits light, which is subsequently collected and analyzed using a spectrometer. This emitted light contains characteristic atomic and ionic emissions, allowing for the identification and quantification of various elements present in the steel. LIBS is also a non-destructive technique, providing real-time results and requiring minimal sample preparation. Both XRF and LIBS offer multiple benefits in terms of speed, non-destructiveness, and user-friendliness for inspecting the chemical composition of steel coils. These spectroscopic techniques play a vital role in quality control and assurance, ensuring that the steel meets the necessary specifications and standards for diverse industrial applications.

- Q: How are defects in steel coils repaired?

- Defects in steel coils can be repaired through several methods depending on the type and extent of the defect. One common approach is known as welding repair, which involves using specialized welding techniques to fix the defect. This method is typically used for minor defects such as cracks or small holes in the coil. The damaged area is cleaned, prepped, and then welded using appropriate welding rods or wires to ensure a strong and durable repair. For more severe defects, such as large holes or significant damage to the coil, a patching technique may be employed. This involves cutting out the damaged section and replacing it with a new piece of steel. The patch is usually welded to the intact areas of the coil, ensuring a secure and seamless repair. In some cases, defects can also be addressed through grinding or sanding techniques. This is often used for surface defects like scratches or blemishes that do not compromise the structural integrity of the coil. Grinding or sanding the affected area smooths out the defect, improving the appearance and preventing further damage. It is worth noting that the repair method chosen depends on factors such as the specific defect, the material of the coil, and the intended application of the steel. The repair process may also involve additional steps such as heat treatment or surface finishing to restore the coil to its original condition. Overall, repairing defects in steel coils requires the expertise of skilled technicians and specialized equipment. It is crucial to address these defects promptly to prevent further damage and ensure the coil's performance and longevity.

- Q: I already have the county permits and bank loan, but the foundation hasn't been poured. Is it too late to convert to steel?

- Steel is going to be a whole different world. You will need to go back to square one and get house plans that are drawn for structural steel. First thing you need to do is find a builder that knows how to build with steel and get an idea of the price.

- Q: How are steel coils cleaned before use?

- Steel coils are cleaned before use through a process known as pickling. Pickling is a chemical treatment that helps remove any impurities, scale, rust, and other contaminants from the surface of the steel coils. The initial step involves the steel coils being immersed in an acid bath, typically a mixture of hydrochloric acid and sulfuric acid. This acid solution helps dissolve any rust, scale, and other surface impurities. The duration of the immersion depends on the extent of contamination and the desired cleanliness level. After the pickling process, the coils are thoroughly rinsed with water to remove the acid solution and any remaining residue. This step is crucial to prevent further corrosion or chemical reactions. Once the rinsing is complete, the coils are often subjected to a drying process to remove any remaining moisture. This can be done through air drying, using high-pressure air blowers, or by passing the coils through heated chambers. After the cleaning process, the steel coils are now ready for use in various applications such as manufacturing, construction, or any other industry that requires high-quality steel products. The pickling process ensures that the coils have a clean, smooth, and corrosion-resistant surface, allowing them to perform effectively and meet the desired specifications.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Stainless okorder

- Q: Its big and expensive and i don't know if it would have a logical purpose but its sharp as hell and awesome. Anyways, its made from surgical steel and all i have found on the internet is that its probably 316L (w/e that means). I have another knife made from 440 stainless steel and as far as i know that is pretty much the hardest stainless metal. So why would the more expensive one be made from surgical steel?

- Surgical Steel Knives

Send your message to us

Hot Sale Grade of Stainless Steel Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords