Hot Rolled Steel Sheets Boats ST37 for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of steel sheets:

Widely used in petrochemistry,chemistry,electricity,boiler and vessel manufacture,and could

be made into reactor,heat exchange facility,segregator,sphere vessel,oil tank,liquid gas storage

tank,nuclear reactor press shell,turbine and other machines

Also can used for Roof, outer walls, ovens, lined plastic window, light steel keel.

Festures of steel sheets:

ASTM / ASME SB 162 UNS 2200 ( NICKEL 200 ) / UNS 2201 (NICKEL 201 )

ASTM / ASME SB 127UNS 4400 (MONEL 400 )

ASTM / ASME SB 424 UNS 8825 (INCONEL 825)

ASTM / ASME SB 168UNS 6600 (INCONEL 600 ) / UNS 6601 ( INCONEL 601 )

ASTM / ASME SB 443 UNS 6625 (INCONEL 625)

ASTM / ASME SB 574 UNS 10276 ( HASTELLOY C 276 )

ASTM / ASME SB 462 UNS 8020 ( ALLOY 20 / 20 CB 3 )

Specifications of steel sheets:

Hold rolled steel coil | ||

Brand Name: | ALUSTAR-HR | |

Standard: | ASTM A387,GB713-2008,EN10028-2-2003,JIS G4109-2003, ASTM A542,etc. | |

Grade: | Q195-Q345, SS400, ASTM A36, SAE1006, SAE1008, S235JR-S355JR, ST37, ST54, etc. | |

Size: | Thickness: | 0.2-25mm |

Width: | ≤ 2000mm | |

Length: | Coil or client’s requirements | |

Surface: |

pickling/ black | |

Treat: | Oiled or pickling or no treat | |

Coil ID: | 508 /610mm | |

Coil Weight: | as request | |

Type : | coil or sheets | |

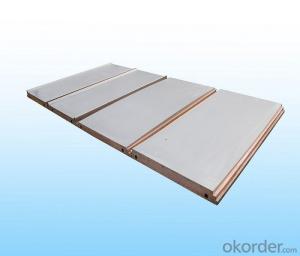

Images of steel sheets:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: My greatgrandfather is listed as a smelterman converter in 1911 in Anaconda, Montana. What would his job have been at that time?

- Converting is a term used to describe a number of metallurgical smelting processes. The most commercially important use of the term is in the treatment of molten metal sulfides to produce crude metal and slag, as in the case of copper and nickel converting. Smelting is then defined as a chemical reduction, or a form of extractive metallurgy. The main use of smelting is to produce (extract) a metal from its ore. This includes iron extraction (for the production of steel) from iron ore, and copper extraction and other base metals from their ores. This would indicate he most likely worked with the furnaces used to get pure copper from copper ore, most likely mined in Montana.

- Q: what is solar panel?and what is solar cell?do solar cells compose solar panels?

- I think rims are also hubcaps - but I'm not sure.

- Q: Electroplating gold, in a copper plate of both sides of the gold-plated, (1250x2) square centimeter of the area, it takes about 5 grams of gold. What do I need?

- The thickness of electroplated coating is usually um, and most of the coating thickness (such as zinc plating) is below 10um.1U, that is, 1um, is equivalent to 10^ (-6) meters, that is, one millionth of a meter, or 1/1000 millimeters.

- Q: The statue of liberty was orig. a copper color. After exposed to the air , she turned a greenish color. what kind of change happend? Explain. First to answer with a good answer wins best answer.Thanks.

- Original color of copper is brown. When it exposed to the air, it will oxidized and form copper(II) ion. The reaction of copper(ii) ion with water from air produces copper (II) hydroxide and normally its color is blue or greenish. So if you want the name of reaction, it is corrosion of metal or oxidation.

- Q: Has anyone tried to build their own solar panel yet?

- The copper panel can be made with 78 OD copper tubing soldered to a 114 header, top and bottom . A 1 T at the bottom for inlet glycol supply and a 1 T at the top for hydronic return .This way you can use one pan-ell or a series of panel ls in a row . Soldered to flat 1|8 thick flat copper . You need a frame and room for expansion . The glass is the problem .Solar glass is Prism shaped and can not be cut .The slightest crack will make the whole sheet Shatter .

- Q: Pl. give me links about corrosion control and cathodic protection in?

- The science of cathodic protection (CP) was born in 1824, when Sir Humphrey Davy made a presentation to the Royal Society of London: The rapid decay of the copper sheeting on His Majesty's ships of war, and the uncertainty of the time of its duration, have long attracted the attention of those persons most concerned in the naval interest of the count. . I entered into an experimental investigation upon copper. In pursuing this investigation, I have ascertained many facts . to illustrate some obscure parts of electrochemical science. seem to offer important application. Davy succeeded in protecting copper against corrosion from seawater by the use of iron anodes. From that beginning, CP has grown to have many uses in marine and underground structures, water storage tanks, gas pipelines, oil platform supports, and many other facilities exposed to a corrosive environment (see Corrosion Costs Study findings). Recently, it is proving to be an effective method for protecting reinforcing steel from chloride-induced corrosion. I hope these links help. Best of luck with it.

- Q: Why should we use industrial salt to bury the ground copper?

- Can also use long-acting chemical drag down agent, long acting chemical resistance reducing agent, resistance reduction effect is obvious, stable performance, long use cycle.

Send your message to us

Hot Rolled Steel Sheets Boats ST37 for Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches