Hot Rolled Stainless Steel Sheet With Competitiver Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

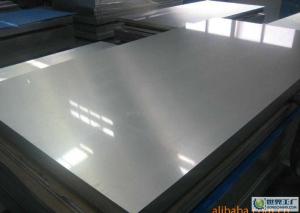

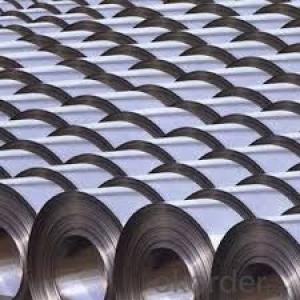

1.Structure of Product Description

Stainless steel sheet/stainless steel plate/stainless steel slabs are all widely used in the field of construction field and decoration field, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

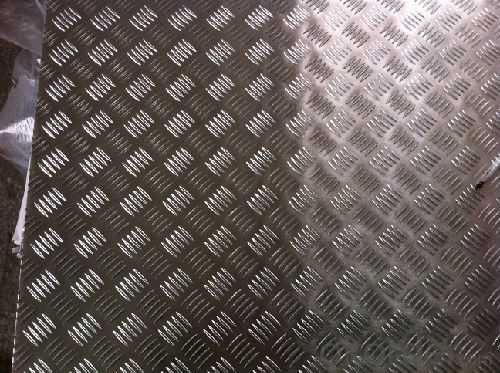

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

500mm*1000mm, 1000mm*2000mm, 1500mm*3000mm,1500mm*6000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: How do I prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, it is important to keep them clean and dry. Avoid exposure to harsh chemicals or high chloride environments, as they can cause corrosion. Regularly inspect the sheets for any signs of damage or pitting, and promptly address any issues. Applying a protective coating or using stainless steel cleaners can also help to prevent pitting and maintain the appearance and integrity of the sheets.

- Q: Can stainless steel sheets be used for water tanks?

- Yes, stainless steel sheets can be used for water tanks. Stainless steel is a popular choice for water tanks due to its corrosion-resistant properties. It is highly resistant to rust and can withstand exposure to water and moisture without deteriorating. Stainless steel is also hygienic, as it does not react with water or leach any harmful substances into it. Additionally, stainless steel tanks are durable and long-lasting, making them a reliable option for storing water. Overall, stainless steel sheets are a suitable material for constructing water tanks, providing a safe and reliable storage solution for water.

- Q: How do you remove fingerprints from stainless steel sheets?

- To remove fingerprints from stainless steel sheets, there are a few effective methods you can try: 1. Soap and water: Start by wiping the surface with a soft cloth or sponge soaked in warm soapy water. Gently rub the affected area in circular motions. Rinse the cloth or sponge and wipe away any soap residue. Dry the stainless steel sheet with a clean, lint-free cloth. 2. Vinegar solution: Mix equal parts of white vinegar and water in a spray bottle. Spray the solution directly onto the fingerprints and let it sit for a few minutes. Wipe the surface with a soft cloth in a circular motion, ensuring to follow the grain of the stainless steel. Rinse the cloth and wipe away any remaining vinegar. Dry the sheet thoroughly. 3. Glass cleaner: Spray a small amount of glass cleaner onto a soft cloth and gently rub the fingerprints. Again, wipe in circular motions, following the grain of the stainless steel. Repeat if necessary, rinsing the cloth and reapplying cleaner as needed. Finally, dry the surface with a clean cloth. 4. Stainless steel cleaner: There are various commercial stainless steel cleaners available that can effectively remove fingerprints. Follow the instructions provided on the product and apply it to the affected areas. Wipe the surface with a soft cloth, following the grain of the stainless steel, and buff it to a shine. Make sure to read and follow any safety precautions mentioned on the product. Regardless of the method you choose, always remember to test it on a small, inconspicuous area first to ensure it doesn't damage or discolor the stainless steel sheet. Additionally, avoid using abrasive cleaners or scrub brushes, as they can scratch the surface. With proper care and regular cleaning, you can keep your stainless steel sheets looking shiny and fingerprint-free.

- Q: Can stainless steel sheets be used for architectural mesh?

- Yes, stainless steel sheets can be used for architectural mesh. Stainless steel is a popular material choice for architectural applications due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel sheets can be perforated, woven, or expanded to create intricate mesh patterns that are commonly used in architectural projects such as facades, sunscreens, balustrades, and decorative screens. The versatility of stainless steel allows for various design possibilities, and its strength ensures long-lasting performance. Additionally, stainless steel mesh can be customized in terms of aperture size, wire diameter, and finish to meet specific architectural requirements.

- Q: Can stainless steel sheets be used for heat exchangers?

- Indeed, heat exchangers can utilize stainless steel sheets as a viable option. The preference for stainless steel in heat exchangers arises from its exceptional corrosion resistance, durability, and exemplary heat transfer characteristics. This material exhibits exceptional resilience against high temperatures and remains impervious to both chemical and physical harm, rendering it suitable for a diverse range of industrial applications. Moreover, the malleability of stainless steel sheets allows for effortless fabrication into diverse forms and dimensions, facilitating personalized customization to fulfill precise heat exchanger prerequisites.

- Q: Can stainless steel sheets be used for wastewater treatment?

- Certainly, wastewater treatment can employ stainless steel sheets. Stainless steel boasts remarkable corrosion resistance and can endure harsh chemicals and environments, rendering it an optimal substance for wastewater treatment purposes. Its utility extends to the construction of tanks, pipes, and other equipment employed in the treatment procedure. Moreover, stainless steel sheets are effortlessly cleaned and maintained, diminishing the chances of contamination. Furthermore, stainless steel qualifies as a sustainable material since it can be recycled, thereby presenting an environmentally conscious option for wastewater treatment facilities.

- Q: When milling the stainless steel plate, how can he deform?

- 4. roughing and finishingThe above methods hope to be useful to you

- Q: Can stainless steel sheets be used for chemical reactors?

- Indeed, chemical reactors can indeed utilize stainless steel sheets. The utilization of stainless steel in chemical reactors is quite popular due to its remarkable resistance to corrosion. Its ability to resist chemical reactions with various substances is commendable, thus rendering it suitable for handling corrosive chemicals or environments. Moreover, stainless steel sheets are renowned for their durability, exceptional strength, and capacity to endure high temperatures. Hence, they are ideal for deployment in chemical reactors that may operate under extreme conditions. Furthermore, stainless steel is effortlessly maintainable and easy to clean, which is a pivotal factor in ensuring the purity and integrity of the reaction process. In conclusion, stainless steel sheets are widely employed in the construction of chemical reactors and are widely recognized as a trustworthy and efficient choice of material for this purpose.

- Q: What drill can drill stainless steel?

- Drilling stainless steel materials, there are two main domestic products: high-speed steel bit, carbide drill. Carbide hollow drill is of high toughness and good wear resistance. It is recommended that you use this material. The price depends on the specifications you need.

- Q: Can stainless steel sheets be used for elevator wall panels?

- Elevator wall panels can indeed be constructed using stainless steel sheets. The utilization of stainless steel as a material for elevator interiors is highly favored due to its robustness, cleanliness, and aesthetic attractiveness. It imparts a sleek and contemporary appearance that enhances the overall look of the elevator. Furthermore, stainless steel is resistant to corrosion, staining, and scratching, rendering it suitable for high-traffic areas such as elevators. Moreover, it is effortless to clean and maintain, guaranteeing that the elevator walls remain in optimal condition for an extended period. What's more, stainless steel sheets can be tailored to meet specific design requirements and preferences, offering a plethora of finishes, patterns, and colors that can harmonize with the building or elevator's design. Ultimately, stainless steel sheets prove to be a superb option for elevator wall panels.

Send your message to us

Hot Rolled Stainless Steel Sheet With Competitiver Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords