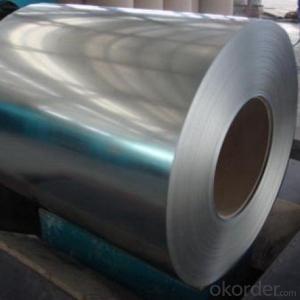

Hot Rolled Stainless Steel NO.1 Finish Grade 304 With Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications for Stainless Steel Coils/Sheets:

Prodcut:Stainless Steel Coil

Thinckness: 0.20mm-8.0mm

Width:1000mm, 1219mm(4 feet), 1250mm, 1500mm, 1524mm(5 feet),

1800mm, 2000mm, 2200mm, 2500mm,and customizable

Ni:0.8~1.2% Cu:1.4~1.5% Cr:14

Standard: ASTM, JIS, GB, BS, DIN etc

Grade: 200series&300series&400series

Surface finish: 2B, BA, 8K, 6K, Mirror Finished, No1, No2, No4, Hair Line with PVC

Manufacture technology: cold rolled/hot rolled

Thickness Tolerance: +/-0.1mm

Width Tolerance: +/-10mm

200 Seriers: 201,202

300 Seriers: 301, 304, 304L, 316L, 309, 310S,321

400 Seriers: 410, 410S, 409L,430

Export Markets for Stainless Steel Coils/Sheets:

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application for Stainless Steel Coils/Sheets

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

Detail picture for Stainless Steel

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you remove oil stains from stainless steel sheets?

- To remove oil stains from stainless steel sheets, you can start by wiping the surface with a clean, soft cloth dampened with warm water and mild dish soap. If the stain persists, apply a small amount of vinegar or rubbing alcohol onto the cloth and gently rub the affected area. Rinse with water and dry thoroughly to avoid water spots.

- Q: Are stainless steel sheets suitable for elevator wall panels?

- Yes, stainless steel sheets are suitable for elevator wall panels. Stainless steel is a popular material choice for elevator wall panels due to its durability, corrosion resistance, and aesthetic appeal. Elevators are high-traffic areas that require a material that can withstand constant use and potential impact. Stainless steel sheets are robust and can withstand wear and tear. Additionally, stainless steel is highly resistant to corrosion, making it suitable for environments with high humidity or exposure to chemicals. Furthermore, stainless steel has a sleek and modern appearance that adds a touch of elegance to the elevator interior. Overall, stainless steel sheets are a reliable and aesthetically pleasing choice for elevator wall panels.

- Q: What type of stainless steel plate made by imported vibrating disk?

- Jing Xin sharp vibration disk equipment is still very good, is a good choice. Kunshan Jing Xin Rui vibration disk equipment factory is a professional manufacturer of non-standard vibrating disk enterprises. Main vibrating disk, linear vibrator, control box and so on, the products are widely used in light industry, machinery, electronics, electrical appliances, hardware, plastics, toys, medicine, food and other industries.

- Q: Can stainless steel sheets be used in food processing industries?

- Stainless steel sheets find extensive use in the food processing industry due to their versatility. They possess exceptional resistance against corrosion, rendering them perfect for environments involved in food processing, storage, or handling. Moreover, their hygienic nature facilitates easy cleaning and prevents any unwanted reactions with the food, ensuring the preservation of its quality and safety. These sheets are employed for crafting an array of food-oriented surfaces, including preparation areas, workstations, counters, sinks, shelves, storage tanks, as well as essential equipment like mixers, conveyors, and ovens. Furthermore, their durability and ability to withstand high temperatures make them an excellent choice for a broad spectrum of food processing operations.

- Q: Can stainless steel sheets be used for medical implants or devices?

- Yes, stainless steel sheets can be used for medical implants or devices. Stainless steel is a commonly used material in the medical field due to its high strength, corrosion resistance, and biocompatibility. It is particularly suitable for applications such as surgical instruments, orthopedic implants, and dental tools, where durability and hygiene are essential.

- Q: Can stainless steel sheets be used in decorative applications?

- Certainly, decorative applications can certainly make use of stainless steel sheets. Stainless steel possesses great versatility, allowing it to be shaped, patterned, and finished in a variety of ways, rendering it an exceptional option for decorative purposes. Its sleek and contemporary look adds a dash of sophistication to any area, and it can be utilized in a multitude of ways, such as wall cladding, backsplashes, cabinet fronts, countertops, and furniture embellishments. Moreover, stainless steel sheets exhibit remarkable durability, resistance to corrosion, and ease of maintenance, making them an ideal choice for both indoor and outdoor decorative applications.

- Q: Can stainless steel sheets be used for wastewater treatment?

- Yes, stainless steel sheets can be used for wastewater treatment. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions and corrosive elements often found in wastewater treatment processes. Additionally, its smooth surface makes it easy to clean and maintain, ensuring long-term durability and effectiveness in treating wastewater.

- Q: Can stainless steel sheets be used for solar panels?

- Solar panels can indeed utilize stainless steel sheets. This material possesses a strong and reliable nature that withstands corrosion, thus making it suitable for long-term and outdoor usage. It offers exceptional defense against environmental elements like moisture and UV radiation, which are commonly encountered in solar panel installations. Furthermore, stainless steel showcases commendable thermal conductivity, promoting efficient dissipation of heat from the solar cells. This characteristic aids in maximizing the energy conversion efficiency of the panels. Additionally, stainless steel sheets present a sleek and polished surface, enhancing the visual appeal of the solar panels. All in all, stainless steel sheets are a reasonable and widely chosen option for the production of solar panels due to their durability, resistance to corrosion, thermal conductivity, and aesthetic attractiveness.

- Q: What is the minimum thickness available for stainless steel sheets?

- The minimum thickness available for stainless steel sheets can vary depending on the specific grade and manufacturer. However, in general, stainless steel sheets are commonly available in thicknesses ranging from 0.4mm to 6mm. Some manufacturers may offer even thinner sheets, such as 0.3mm, for specialized applications. It is important to consult with the supplier or manufacturer to determine the exact minimum thickness available for your specific requirements.

- Q: What does 8K stainless steel mean?

- The stainless steel mirror panel is polished by polishing the surface of BA, 2B or No.1 on an initial surface like a mirror surface (8K, mirror or No.8).

Send your message to us

Hot Rolled Stainless Steel NO.1 Finish Grade 304 With Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords