300 Series Hot Rolled Stainless Steel NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment&Delivery

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

Application of Stainless Steel Coils

(1) Boiler heat exchanger,

(2) Chemical industries,

(3) Hardware fields,

(4) Construction material,

(5) Kitchen utensils,

(6) Building construction,

(7) Medical equipment,

(8) chemical tank,

(9) pipe etc

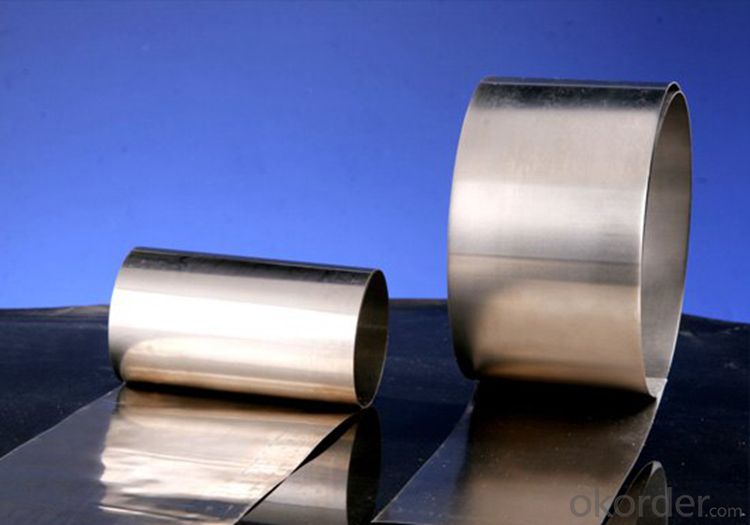

Detail picture for Stainless Steel

FAQ for Stainless Steel

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q: How do you calculate the cost of a stainless steel sheet?

- To calculate the cost of a stainless steel sheet, there are a few factors that need to be considered. 1. Determine the dimensions: The first step is to know the length, width, and thickness of the stainless steel sheet. These measurements will determine the amount of material needed, which is a significant factor in calculating the cost. 2. Determine the grade: Stainless steel sheets come in various grades, such as 304, 316, or 430. Each grade has different properties and costs associated with it. The grade required for a specific application will influence the price of the sheet. 3. Determine the finish: Stainless steel sheets can have different finishes, including brushed, polished, or patterned. The finish required will impact the cost as each finish requires different processes and materials. 4. Consider quantity: The quantity of stainless steel sheets needed can also affect the cost. Bulk orders often come at a discounted price, whereas smaller quantities may be subject to higher prices. 5. Research suppliers: It is crucial to research different suppliers and compare prices. Prices can vary depending on the supplier's location, reputation, and market conditions. 6. Additional costs: Some additional costs may be involved, such as transportation, handling, or cutting fees. It is important to inquire about these costs when obtaining quotes from suppliers. By considering these factors and doing thorough research, one can accurately calculate the cost of a stainless steel sheet.

- Q: Can stainless steel sheets be used for decorative purposes?

- Certainly, decorative purposes can be served by stainless steel sheets. Renowned for its sleek and contemporary look, stainless steel is a widely preferred option for diverse decorative uses. Its applications span across interior design, architecture, and even art installations. Stainless steel sheets can be personalized to fashion distinctive patterns, textures, and finishes, rendering them ideal for crafting captivating and visually enticing decorative elements. Moreover, stainless steel boasts exceptional durability, corrosion resistance, and simple maintenance, making it a pragmatic choice for both indoor and outdoor decorative applications.

- Q: What does stainless steel sheet S2 stand for?

- Stainless steel sheet S2 stands for thickness 2mm

- Q: What are the different surface finishes available for stainless steel sheets?

- There are several different surface finishes available for stainless steel sheets, each offering unique characteristics and aesthetics. 1. No.1 Finish: This is the most common and widely used finish for stainless steel sheets. It has a rough, dull appearance with visible grain lines. No.1 finish is obtained by hot rolling the stainless steel and is suitable for applications where a rough finish is acceptable. 2. No.2B Finish: This finish is obtained by cold rolling the stainless steel and then annealing it, resulting in a smooth, reflective surface with a slightly dull appearance. It is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. No.2D Finish: Similar to No.2B finish, No.2D finish is achieved by cold rolling and annealing the stainless steel. However, it has a smoother and shinier appearance, making it suitable for applications requiring a more polished look. 4. No.3 Finish: Also known as a brushed finish, No.3 finish is achieved by polishing the stainless steel with abrasive belts or brushes. It has a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. No.4 Finish: This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than No.3 finish. It has a more refined and smoother appearance, often used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. No.8 Finish: Also known as a mirror finish, No.8 finish is achieved by polishing the stainless steel with progressively finer abrasive materials until a highly reflective surface is obtained. It provides a glossy, mirror-like appearance, ideal for architectural and decorative applications. 7. Hairline Finish: Hairline finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are some of the most common surface finishes available for stainless steel sheets. The choice of finish depends on the desired aesthetics, functionality, and application requirements.

- Q: What are the common uses of stainless steel sheets?

- Stainless steel sheets have a wide range of common uses due to their durability, corrosion resistance, and aesthetic appeal. Some of the most common applications of stainless steel sheets include kitchen appliances, automotive components, industrial equipment, construction materials, and decorative purposes.

- Q: Are stainless steel sheets suitable for elevator interiors?

- Elevator interiors can greatly benefit from the use of stainless steel sheets. This material is both durable and versatile, providing numerous advantages for elevator design and construction. Its strength and resistance to corrosion make it the perfect choice for enduring heavy usage and potential exposure to moisture or chemicals that are commonly found in elevator environments. Customizing and fabricating stainless steel sheets to fit specific elevator dimensions and designs is a simple task. They can be polished to a high shine, adding a sleek and modern touch that complements various interior styles. Moreover, stainless steel is easy to clean and maintain, making it a practical option for heavily trafficked areas like elevators. Not only is stainless steel a sustainable material that can be fully recycled, but it also has a long lifespan, reducing the need for frequent replacements. Additionally, it offers excellent fire resistance, which is crucial for ensuring the safety of elevator occupants. In summary, stainless steel sheets offer a durable, visually appealing, and low-maintenance solution for elevator interiors, making them highly suitable for use in elevators.

- Q: How do I prevent finger marks on stainless steel sheets?

- To prevent finger marks on stainless steel sheets, you can try a few simple steps. Firstly, make sure to clean the sheets regularly using a mild detergent or stainless steel cleaner to remove any existing fingerprints. Next, consider applying a protective coating or film specifically designed for stainless steel surfaces, which can provide a barrier against smudges and fingerprints. Additionally, try to handle the sheets with clean and dry hands to minimize the transfer of oils and dirt. Finally, consider using microfiber or lint-free cloths for cleaning instead of rough materials that can leave scratches or streaks.

- Q: How do you remove scratches from mirror-finish stainless steel sheets?

- To remove scratches from mirror-finish stainless steel sheets, you can follow these steps: 1. Clean the surface of the stainless steel sheet with a mild detergent and warm water, then dry it thoroughly. 2. Identify the direction of the grain on the stainless steel sheet. The grain usually runs in one direction and appears as faint lines. 3. Using a non-abrasive stainless steel cleaner or a mixture of baking soda and water, gently rub the scratched area along the grain with a soft cloth or sponge. 4. Continue rubbing in a consistent motion until the scratches start to fade. Avoid applying excessive pressure to prevent further damage. 5. Rinse the surface with clean water and wipe it dry with a soft cloth. 6. If the scratches are still visible, you can try using a stainless steel scratch remover or a metal polish specifically designed for stainless steel. Follow the product instructions and apply it to the scratched area following the grain. 7. Once the scratches are no longer visible, clean the surface again with mild detergent and water, then dry it thoroughly to restore the mirror-finish appearance.

- Q: Are stainless steel sheets suitable for high-traffic areas?

- Yes, stainless steel sheets are highly suitable for high-traffic areas. They are durable, resistant to corrosion, and can withstand heavy use. Additionally, stainless steel sheets have a sleek and modern appearance, making them a popular choice for public spaces such as airports, hospitals, and commercial buildings.

- Q: Can stainless steel sheets be used for signage or lettering?

- Yes, stainless steel sheets can be used for signage or lettering. Stainless steel is a highly durable and versatile material that is commonly used in various applications, including signage. It offers excellent resistance to corrosion, making it suitable for both indoor and outdoor use. Stainless steel sheets can be easily fabricated and cut into different shapes and sizes, allowing for the creation of customized signage and lettering designs. Additionally, stainless steel has a sleek and modern appearance, making it an attractive option for signage in commercial or professional settings. Overall, stainless steel sheets provide a reliable and long-lasting solution for signage and lettering needs.

Send your message to us

300 Series Hot Rolled Stainless Steel NO.1 Finish

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords