Hot Rolled Spring Steel Round Bar 16mm with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

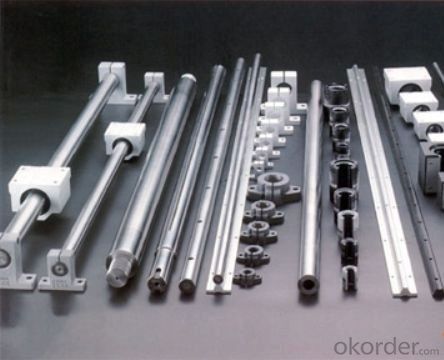

OKorder is offering Hot Rolled Spring Steel Round Bar 16mm with High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Spring Steel Round Bar 16mm with High Quality is widely used to make the bearing used in automobile, tractor engine, transmission and the wheel. And it also used to make the main bearing for the machine tools, electrical machinery, mining machinery, electric locomotives,mechanical ventilation and high speed of grinding wheel spindle etc

Product Advantages:

OKorder's Hot Rolled Spring Steel Round Bar 16mm with High Quality are durable, diversified and qualified.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: 20CrNiMoA 20CrNi2MoA 16Cr2Ni4MoA 12Cr2Ni3Mo5A 20Cr2Ni4A 20Cr2Ni2MoA

Cr4Mo4V Cr15Mo4 W9Cr4V2Mo W18Cr4V W6Mo5Cr4V2 5CrMnMo 60CrMnMoNi 37CrA 55SiMoVA etc

Certificates: ISO, SGS, BV, CIQ

Length:6m 8m 9m 12m

Packaging: Packed in bundles with standard export sea-worthy package or as customer require

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: How many types of bearing steel that OKorder.com can supply?

A4: Two types, carbon spring steel and alloy spring steel

Images:

- Q: What are the most common alloys used in special steel?

- The most common alloys used in special steel are stainless steel, high-speed steel, tool steel, and carbon steel.

- Q: Can special steel be used in the telecommunications industry?

- Yes, special steel can be used in the telecommunications industry. It is often used in the construction of telecommunication towers, antennas, and transmission lines due to its high strength, corrosion resistance, and durability.

- Q: How does special steel perform in terms of corrosion resistance in marine environments?

- Special steel alloys, specifically designed for marine environments, exhibit excellent corrosion resistance. Due to their higher levels of alloying elements like chromium, nickel, and molybdenum, these steels form a protective oxide layer that prevents rusting and pitting, even when exposed to saltwater and other harsh marine conditions. Their exceptional corrosion resistance ensures prolonged durability, reduced maintenance, and enhanced performance in marine environments.

- Q: Can special steel be used for making power generation equipment?

- Yes, special steel can be used for making power generation equipment. Special steels are specifically designed to have enhanced properties such as high strength, corrosion resistance, heat resistance, and wear resistance. These properties make special steel suitable for use in demanding applications such as power generation equipment, which often operates under high temperatures and pressures. Power generation equipment, such as turbines, boilers, and generators, require materials that can withstand harsh operating conditions and deliver reliable performance over an extended period. Special steel grades, such as stainless steels, nickel-based alloys, and heat-resistant steels, are commonly used in the construction of power plants and power generation equipment. Stainless steels are frequently used in power generation due to their excellent corrosion resistance, which is crucial for equipment exposed to high moisture or aggressive environments. Nickel-based alloys are renowned for their exceptional high-temperature strength, making them ideal for components subjected to extreme heat, such as turbine blades or exhaust systems. Heat-resistant steels, on the other hand, are specifically designed to retain their mechanical properties at elevated temperatures, making them suitable for applications such as boilers and heat exchangers. In summary, special steel offers a range of desirable properties that make it highly suitable for manufacturing power generation equipment. Its strength, corrosion resistance, heat resistance, and wear resistance make it an excellent choice for withstanding the demanding conditions found in power plants and ensuring the reliable and efficient generation of electricity.

- Q: How is special steel used in the production of turbine blades?

- Special steel is used in the production of turbine blades due to its exceptional properties such as high strength, corrosion resistance, and heat resistance. These blades must withstand extreme conditions, including high temperatures and pressures, as well as rotational forces. Special steel provides the necessary strength and durability to ensure the blades can effectively convert kinetic energy into mechanical power.

- Q: What are the different alloying elements used in special steel?

- Some of the different alloying elements used in special steel include chromium, nickel, molybdenum, vanadium, tungsten, and cobalt. These elements are added in varying amounts to enhance the steel's specific properties such as corrosion resistance, strength, hardness, and heat resistance.

- Q: How does special steel contribute to the power generation equipment industry?

- Special steel plays a crucial role in the power generation equipment industry by offering enhanced performance, durability, and reliability. Power generation equipment, such as turbines, generators, and transformers, operate under severe conditions including high temperatures, pressure, and corrosive environments. Special steel, with its unique properties and characteristics, addresses these challenges and contributes significantly to the industry. One of the key advantages of special steel in power generation equipment is its ability to withstand high temperatures. Special steel alloys, such as heat-resistant steels, are designed to perform under extreme conditions, enabling power plants to operate at elevated temperatures without compromising efficiency or safety. These steels maintain their strength, structural integrity, and resistance to creep and fatigue even at the highest operating temperatures, ensuring the reliability and longevity of the equipment. Furthermore, special steel offers excellent corrosion resistance, which is essential in power generation equipment due to the presence of corrosive substances like water, steam, and chemicals. Stainless steel, for instance, is widely used in power plants for its exceptional resistance to corrosion, preventing equipment degradation and minimizing maintenance costs. By using special steel, power generation companies can reduce downtime and enhance overall efficiency. Special steel also contributes to the power generation equipment industry by providing exceptional strength and mechanical properties. This is particularly important for large-scale equipment such as turbines and generators, which are subjected to high mechanical loads. High-strength special steel allows these components to withstand the stress and pressure, ensuring their safe and reliable operation over an extended period. Moreover, special steel's unique properties, such as high hardness and wear resistance, make it suitable for critical components like blades and rotors, reducing the risk of failure and enhancing overall performance. In summary, special steel is an indispensable material in the power generation equipment industry. Its ability to withstand high temperatures, resist corrosion, and provide exceptional strength and mechanical properties ensures the reliability, durability, and efficiency of power plants. By utilizing special steel, power generation companies can enhance their equipment's performance and reduce maintenance costs, ultimately contributing to the sustainable and reliable production of electricity.

- Q: How does special steel perform in high-temperature oxidation resistance?

- Special steel is specifically designed to have excellent high-temperature oxidation resistance. It is able to withstand prolonged exposure to high temperatures without undergoing oxidation, ensuring its structural integrity and performance are maintained even in extreme conditions.

- Q: Can special steel be used in the aerospace defense industry?

- Yes, special steel can be used in the aerospace defense industry. Special steel alloys such as high-strength steels, stainless steels, and nickel-based alloys are commonly utilized in the production of various components and structures for aerospace defense applications. These materials offer excellent mechanical properties, corrosion resistance, and durability, making them suitable for critical applications in the aerospace defense industry.

- Q: How does special steel contribute to the automotive racing machinery industry?

- The automotive racing machinery industry greatly relies on special steel to enhance the performance, durability, and safety of racing vehicles. One significant benefit of special steel is its ability to boost the power and speed of racing cars. Steel alloys like carbon fiber-reinforced steel or high-strength steel offer exceptional strength-to-weight ratios, enabling manufacturers to reduce vehicle weight without compromising structural integrity. This weight reduction enhances acceleration and maneuverability, resulting in increased speed and improved lap times on the track. Apart from performance improvements, special steel also makes racing vehicles safer. Certain steel alloys possess high strength and impact resistance, making them ideal for constructing roll cages, chassis, and other critical safety components. These materials can withstand extreme forces during crashes or collisions, providing enhanced protection for drivers and minimizing the risk of severe injuries. Special steel also contributes to the longevity and durability of automotive racing machinery. The demanding conditions of racing, including high temperatures, vibrations, and mechanical stress, can quickly deform or deteriorate regular steel. However, special steel alloys are specifically engineered to withstand these harsh environments, ensuring racing cars can withstand the sport's rigorous demands without compromising performance or safety. Furthermore, special steel alloys offer excellent thermal conductivity and heat resistance, which are essential for racing vehicles that generate substantial heat during high-speed runs. By efficiently dissipating heat, special steel helps prevent overheating and ensures optimal engine performance, minimizing the risk of mechanical failures and maximizing the lifespan of racing machinery. In summary, special steel significantly contributes to the automotive racing machinery industry by enhancing the performance, durability, and safety of racing vehicles. The use of high-performance steel alloys increases speed, improves lap times, and reduces vehicle weight. Additionally, it provides superior strength and impact resistance, enhancing safety during crashes or collisions. Moreover, special steel alloys offer excellent heat resistance and thermal conductivity, ensuring optimal engine performance and prolonging the lifespan of racing machinery.

Send your message to us

Hot Rolled Spring Steel Round Bar 16mm with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords