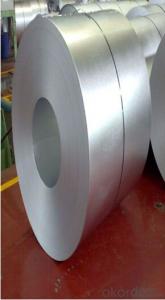

hot dipped galvanized steel sheet in coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thickness | 0.125-0.8mm |

Width | 750-1250mm |

Zinc coating | 50-220g/m2 |

Type | steel coil |

Weight of each package | 3-5mt |

Technology | cold rolled |

Material | SPCC Q195 SGCC SGCH |

Standard | ASTM,GB,JIS,DIN |

ID | 508mm |

Price | FOB XingangUSD800-1200 per mt |

Packing | seaworthy export packing or mill's standard packing or as per client's request. |

Surface treatment | galvanized,passivated,skin pass,bright finished,corrosion resistance.

|

Delivery time | within 35 days after receiving the down payment or irrevocable L/C at sight

|

Payment | 30% down payment of the total value by T/T and the balance must be paid by T/T or irrevocable L/C at sight after the goods finished. |

Application | widely used in construction,household appliance,automobile,light industry,etc. |

- Q: What kind of material does ordinary steel plate refer to in steel market?

- And because of the common strength, there is a single carbon steel plate is made, then the internal molecular interactions is very single, which makes the steel in strength is very limited, there is no better development. But the alloy steel plate is different, because this kind of steel plate because has joined many other elements, this also causes its internal molecular structure to become extremely complex, simultaneously its internal molecular force also becomes extremely strong. It also gives the plate greater in strength increased, and the alloying elements of the steel sheet is fixed on the strength of it development is limitless.

- Q: Are steel sheets suitable for building envelopes or curtain walls?

- Yes, steel sheets are suitable for building envelopes or curtain walls. Steel is a strong and durable material that offers excellent structural integrity and can withstand harsh weather conditions. It is also versatile, allowing for various design possibilities. Additionally, steel sheets can be manufactured with different coatings to enhance their resistance to corrosion and provide an aesthetically pleasing finish.

- Q: What is the difference between a galvanized and stainless steel sheet?

- Galvanized and stainless steel sheets are both types of steel sheets that are used in various applications. However, there are some key differences between these two materials. One major difference is their resistance to corrosion. Galvanized steel sheets are coated with a layer of zinc to protect them from rust and corrosion. This makes them ideal for outdoor applications or environments with high humidity or moisture. On the other hand, stainless steel sheets are made with a combination of chromium and other alloys, which gives them superior corrosion resistance. They can withstand exposure to chemicals, acids, and saltwater, making them suitable for highly corrosive environments. Another difference is their appearance. Galvanized steel sheets have a characteristic silver-gray color due to the zinc coating. Over time, the zinc coating can develop a dull, weathered look. On the contrary, stainless steel sheets have a distinct, shiny appearance that can vary depending on the type of finish applied. This makes stainless steel sheets more aesthetically pleasing and suitable for applications where appearance matters. In terms of strength and durability, stainless steel sheets tend to be stronger and more durable than galvanized steel sheets. Stainless steel has a higher tensile strength, which means it can withstand more force or pressure before breaking. Additionally, stainless steel is more resistant to dents and scratches compared to galvanized steel. Cost is another factor to consider when choosing between galvanized and stainless steel sheets. Galvanized steel sheets are generally more affordable than stainless steel sheets. This makes them a cost-effective option for applications where corrosion resistance is not a top priority. On the other hand, stainless steel sheets are more expensive due to the higher cost of raw materials and the additional processing required to create the stainless steel alloy. In summary, the main differences between galvanized and stainless steel sheets lie in their corrosion resistance, appearance, strength, and cost. Galvanized steel sheets offer good corrosion resistance at a lower cost, while stainless steel sheets provide superior corrosion resistance, strength, and a more attractive appearance at a higher price point.

- Q: Are the steel sheets resistant to impact or bending?

- In general, steel sheets display resistance to both impact and bending. Steel possesses exceptional strength and durability, rendering it less susceptible to external forces like impacts or bending. This is attributed to the material's capacity to absorb and disperse applied energy, leading to minimal deformation or harm. Nevertheless, the extent of resistance to impact and bending may fluctuate based on factors such as sheet thickness, steel type, and any supplementary treatments or coatings that have been applied.

- Q: Can steel sheets be used for decorative architectural elements?

- Yes, steel sheets can definitely be used for decorative architectural elements. Steel is a versatile material that can be shaped and manipulated into various forms, making it suitable for creating visually pleasing designs. Steel sheets can be used to create decorative facades, cladding, screens, panels, and other architectural features. The sheets can be cut, welded, perforated, embossed, or textured to achieve the desired decorative effect. Additionally, steel sheets can be coated or finished in different colors or patterns to further enhance their aesthetic appeal. With its durability, strength, and ability to withstand harsh weather conditions, steel is an excellent choice for both functional and decorative architectural elements.

- Q: How long do steel sheets typically last?

- Steel sheets typically have a long lifespan and can last anywhere from 20 to 50 years, depending on factors such as maintenance, exposure to harsh conditions, and quality of the steel.

- Q: Are steel sheets suitable for mining or construction equipment?

- Yes, steel sheets are highly suitable for mining and construction equipment due to their strength, durability, and resistance to wear and tear. Steel sheets provide excellent structural integrity, making them capable of withstanding heavy loads, harsh working conditions, and extreme weather. Additionally, steel sheets can be easily fabricated and customized to meet the specific requirements of mining and construction equipment, making them a preferred choice in these industries.

- Q: What is the density of steel sheets?

- The density of steel sheets varies depending on the specific type of steel being used. On average, the density of steel sheets ranges from 7.75 to 8.05 grams per cubic centimeter (g/cm³).

- Q: Can steel sheets be used in corrosive chemical environments?

- In corrosive chemical environments, the use of steel sheets is possible, but it is crucial to consider the specific type of steel and its resistance to corrosion. Stainless steel, for instance, is widely employed in such environments due to its excellent corrosion resistance properties. It contains a minimum of 10.5% chromium, which creates a protective oxide layer on the steel's surface, preventing further corrosion. Consequently, stainless steel sheets are suitable for a diverse range of corrosive chemical environments, including those involving acids, alkalis, and salts. However, it is vital to select the appropriate grade of stainless steel that matches the specific corrosive chemicals present in the environment. Furthermore, applying protective coatings or surface treatments can further enhance the corrosion resistance of steel sheets in harsh chemical environments. Seeking advice from corrosion experts or engineers is essential in determining the most suitable steel grade and protective measures for a particular corrosive chemical environment.

- Q: Are steel sheets resistant to termite infestation?

- No, steel sheets are not resistant to termite infestation. Termites can still damage steel sheets by burrowing through them or accessing the structure behind the sheets.

Send your message to us

hot dipped galvanized steel sheet in coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords