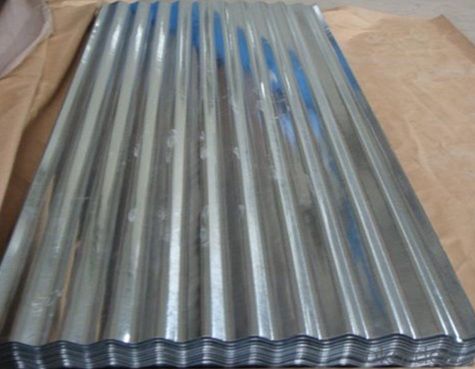

Hot-Dipped Corrugated Steel Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Hot-Dipped Corrugated Steel Roofing Sheet

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: How do steel strips compare to other materials in terms of strength and durability?

- Steel strips are highly sought after in various applications due to their exceptional strength and durability. In comparison to materials like aluminum, plastic, or wood, steel strips consistently outperform in terms of both strength and durability. The high tensile strength of steel allows it to endure significant stretching or pulling forces without breaking or deforming. This makes steel strips ideal for applications requiring structural integrity, such as in the construction, automotive, or aerospace industries. On the other hand, materials like aluminum or plastic tend to have lower tensile strengths, making them less suitable for heavy-duty applications. Additionally, steel strips exhibit excellent durability, enabling them to withstand wear, impact, and harsh environmental conditions without significant damage or degradation. This durability is particularly valuable in industries where materials face constant stress or exposure to extreme temperatures, moisture, or corrosive substances. While other materials may offer some level of durability, steel strips stand out due to their superior resistance against wear and environmental factors. Furthermore, steel strips have a long lifespan, contributing to their overall durability. They are less prone to cracking, warping, or decaying over time, unlike materials such as wood or plastic. This longevity makes steel strips a cost-effective choice in applications where frequent replacements or repairs would be both time-consuming and expensive. In conclusion, steel strips exceed other materials in terms of strength and durability. Their high tensile strength and exceptional resistance to wear and environmental factors make them the preferred choice for various industries. Whether it is for structural support, heavy-duty applications, or long-lasting durability, steel strips consistently demonstrate their superiority over alternative materials.

- Q: How do steel strips compare to other materials like aluminum or plastic?

- Compared to materials like aluminum or plastic, steel strips possess distinct characteristics that set them apart in terms of strength, durability, and versatility. To begin, steel strips are widely recognized for their exceptional strength. Steel boasts a high tensile strength, rendering it more resistant to bending and breaking than aluminum or plastic. This quality enables steel strips to withstand heavy loads and endure harsh conditions, making them suitable for applications where structural integrity is paramount. Furthermore, steel strips exhibit outstanding durability. Unlike aluminum, which is prone to corrosion, steel demonstrates remarkable resistance to rust and can endure exposure to moisture, chemicals, and other environmental factors. This durability guarantees that steel strips maintain their integrity over time, making them ideal for long-term applications. Moreover, steel strips offer exceptional versatility. They can be easily customized and fabricated into various shapes and sizes, enabling a wide range of applications across diverse industries. Due to their adaptability and versatility, steel strips find utility in construction, automotive manufacturing, electrical appliances, and numerous other sectors. While aluminum and plastic possess their own merits, such as being lightweight or cost-effective, steel strips excel in terms of strength, durability, and versatility. The choice between these materials ultimately hinges upon the specific requirements of the project and the desired characteristics necessary to ensure optimal performance.

- Q: What are the standard widths of steel strips?

- Different industries and applications can lead to variations in the standard widths of steel strips. Nevertheless, there exist widely available standard widths that are commonly used. These include 1/2 inch, 3/4 inch, 1 inch, 1.5 inches, 2 inches, 3 inches, 4 inches, 5 inches, 6 inches, 8 inches, 10 inches, and 12 inches. These standard widths find application in construction, automotive, manufacturing, and engineering industries. Moreover, customized widths can also be manufactured to meet specific project or application requirements. To determine the most appropriate standard width for a particular steel strip need, it is crucial to consult a supplier or manufacturer.

- Q: How are steel strips processed for shearing?

- Steel strips are processed for shearing by first unwinding the coil and passing it through a leveler to ensure a flat and even surface. Then, the strips are fed through a shearing machine, where blades cut them into desired lengths or shapes. This process ensures precision and accuracy in obtaining the desired dimensions of the steel strips.

- Q: What are the factors that affect the hardness of steel strips?

- The factors that affect the hardness of steel strips include the composition of the steel, the heat treatment process, the cooling rate, the presence of impurities, and the amount of strain or deformation applied during processing.

- Q: What are the common industry standards for steel strips?

- The specific application and usage of steel strips determine the varying common industry standards. However, the steel industry commonly adheres to several well-known standards. One notable standard is the American Society for Testing and Materials (ASTM) standard. ASTM A109/A109M specifies the requirements for cold-rolled carbon steel strips with a maximum carbon content of 0.25 percent. This standard outlines guidelines for the chemical composition, mechanical properties, and dimensional tolerances of steel strips. Another widely used standard is the International Organization for Standardization (ISO) standard. ISO 9445 covers the dimensions, surface quality, and mechanical properties of continuously hot-rolled steel strips and plates. Additionally, specific regions have their own standards. For instance, the European Committee for Standardization (CEN) has developed the EN 10139 standard, which outlines the requirements for cold-rolled narrow steel strips in Europe. Moreover, industries like automotive, construction, and manufacturing often have their own unique standards and requirements for steel strips. These standards are typically established by industry associations or regulatory bodies to ensure the safety, quality, and performance of steel strips in their respective applications. In conclusion, while there are various common industry standards for steel strips, it is crucial for manufacturers, suppliers, and end-users to consult the applicable standard for their region and specific application to ensure compliance and meet the necessary specifications.

- Q: What are the surface finishing techniques for steel strips?

- There are several surface finishing techniques that can be employed for steel strips, depending on the desired final product and its specific requirements. Some of the commonly used surface finishing techniques for steel strips include: 1. Pickling: This technique involves the use of an acid solution to remove any oxide scale or impurities from the steel strip's surface. Pickling helps in improving the strip's corrosion resistance and prepares it for further processing. 2. Electroplating: It is a process wherein a thin layer of metal is deposited onto the steel strip's surface using an electrolytic bath. Electroplating can enhance the appearance of the strip, improve corrosion resistance, and provide additional properties such as increased hardness or conductivity. 3. Galvanizing: This technique involves coating the steel strip with a layer of zinc to provide protection against corrosion. Galvanizing is commonly used in applications where the steel strip will be exposed to harsh environments. 4. Painting: Applying a layer of paint onto the steel strip's surface can provide both aesthetic appeal and protection against corrosion. Different types of paint coatings can be used, depending on the specific requirements of the application. 5. Grinding and Polishing: These techniques involve the use of abrasive materials to remove any imperfections or roughness from the steel strip's surface. Grinding and polishing can provide a smooth and reflective finish to the strip, which is desirable in certain applications such as decorative or reflective surfaces. 6. Coating: Various types of coatings, such as powder coatings or organic coatings, can be applied to the steel strip's surface to provide protection against corrosion, enhance appearance, or provide specific functional properties. 7. Heat Treatment: Certain heat treatment processes, such as annealing or tempering, can be employed to modify the surface properties of the steel strip. These processes can improve hardness, strength, or other mechanical properties of the strip's surface. It is important to note that the choice of surface finishing technique for steel strips depends on factors such as the desired final properties, application requirements, cost considerations, and environmental impact.

- Q: How are steel strips protected during storage?

- Various methods are employed to safeguard steel strips during storage, with the aim of averting damage and corrosion. One prevalent approach involves applying a protective coating onto the surface of the steel strips. This coating effectively acts as a shield, separating the steel from the surrounding environment, thereby obstructing any contact between the metal and moisture or other corrosive substances. Furthermore, to further minimize the risk of corrosion, it is common practice to store steel strips in a controlled environment with low levels of humidity. To protect against physical harm, steel strips are frequently stored on racks or in specialized containers to limit contact with other objects. Additionally, proper handling and stacking techniques are implemented to avert any bending or warping of the strips. Regular inspections and maintenance play a crucial role in promptly addressing any indications of corrosion or damage, thus prolonging the lifespan of the steel strips.

- Q: What are the factors that affect the surface finish of steel strips?

- Several factors affect the surface finish of steel strips, including the quality of the raw materials used, the type and condition of the equipment used in the manufacturing process, the level of skill and expertise of the operators, the speed and pressure applied during rolling or polishing, the presence of any contaminants or impurities in the environment or on the material itself, and the level of post-processing and finishing applied to the steel strips.

- Q: How are steel strips used in the production of metal signs?

- Steel strips are commonly used in the production of metal signs as they offer several advantages. Firstly, steel strips provide a strong and durable base for the sign, ensuring its longevity and resistance to weather elements. This is important, especially for outdoor signs that are exposed to rain, wind, and sunlight. Additionally, steel strips can be easily shaped and bent into various forms, allowing for the creation of different sign designs. This flexibility makes steel strips a versatile material for sign manufacturers, enabling them to create intricate and custom-made signs. Moreover, steel strips can be coated with different finishes, such as paints, coatings, or laminates, to enhance their appearance and protect them from corrosion. This helps to maintain the aesthetic appeal of the sign and prolong its lifespan. Furthermore, steel strips are often used as a substrate for applying graphics, lettering, or other decorative elements on the sign. They provide a smooth and flat surface, allowing for precise and high-quality printing or application of vinyl decals. Lastly, steel strips can also be easily attached to various mounting systems, such as brackets, frames, or posts, making it convenient to install the metal signs in different locations. In summary, steel strips are an essential component in the production of metal signs due to their strength, versatility, ability to be coated, substrate properties, and ease of attachment. These qualities make steel strips an ideal choice for manufacturing metal signs that are durable, visually appealing, and suitable for various applications.

Send your message to us

Hot-Dipped Corrugated Steel Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords