Home Appliance Applied CRCA

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

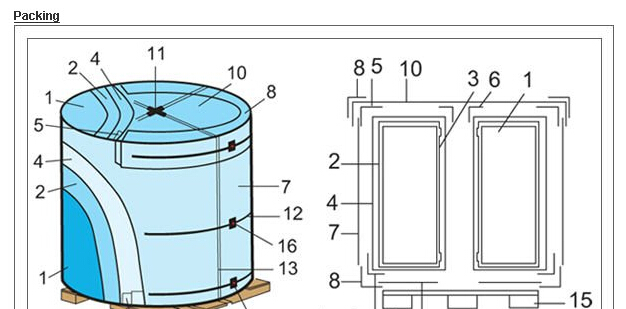

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Si | |

Q195 | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.04 | ≤0.30 |

Mechanical Properties

1. Yield Strength: ≤285MPa

2. Tensile Strength: ≤347MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 34%

(2) Nominal Thickness 0.25mm-<0.40: 36%

(3) Nominal Thickness 0.40-<0.60mm: 38%

(4) Nominal Thickness 0.60-<1.0mm: 40%

(5) Nominal Thickness 1.0-<1.6mm: 41%

(6) Nominal Thickness >1.6mm: 42%

- Q: How are steel products used in the construction of stadiums and arenas?

- Steel products are extensively used in the construction of stadiums and arenas due to their strength, durability, and versatility. They are used for various structural components like beams, columns, and trusses, providing support and stability to the entire structure. Steel is also utilized in roofing systems, façades, and cladding, offering aesthetic appeal and weather resistance. Additionally, steel is employed in the construction of seating, stairs, and walkways, ensuring safety and functionality for spectators. Overall, steel products play a crucial role in creating robust and visually striking stadiums and arenas.

- Q: How is steel sheet metal bent for HVAC ductwork?

- Steel sheet metal is bent for HVAC ductwork using a variety of methods such as hydraulic or mechanical presses, folding machines, or specialized bending tools. The sheet metal is placed in the machine and then bent to the desired angle or shape, ensuring precise measurements and a tight fit for efficient airflow in HVAC systems.

- Q: What are the different types of steel coils and their uses?

- There are several types of steel coils, including hot rolled, cold rolled, galvanized, and stainless steel coils. Hot rolled coils are commonly used in construction and manufacturing industries for structural applications. Cold rolled coils are used in automotive, appliance, and electrical industries for their superior surface finish and dimensional accuracy. Galvanized coils are coated with a layer of zinc, making them corrosion-resistant and suitable for outdoor applications. Stainless steel coils are highly resistant to corrosion and heat, making them ideal for food processing, medical, and chemical industries.

- Q: How is steel plate formed into curved sections for architectural designs?

- Steel plate is formed into curved sections for architectural designs through a process called plate rolling. In this process, the steel plate is heated and then passed through a series of rollers that gradually bend it into the desired curved shape. The amount of curvature is determined by the diameter of the rollers and the number of passes the plate makes through them. This allows architects to create unique and aesthetically pleasing curved structures using steel plate.

- Q: What are the different types of steel coatings for corrosion prevention?

- There are several types of steel coatings available for corrosion prevention, including galvanized coatings, metallic coatings, organic coatings, and ceramic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface to provide a protective barrier against corrosion. Metallic coatings, such as aluminum or zinc-aluminum, offer excellent corrosion resistance due to their sacrificial properties. Organic coatings, such as epoxy or polyurethane, create a protective film on the steel surface to prevent contact with corrosive elements. Ceramic coatings, like porcelain enamel or vitreous enamel, offer high resistance to corrosion, chemicals, and extreme temperatures. Each type of coating has its advantages and suitability for specific applications.

- Q: What are the different types of steel fasteners used in construction?

- There are several different types of steel fasteners commonly used in construction, including bolts, screws, nails, and rivets. These fasteners are essential for joining various components together, providing strength and stability to structures. Bolts are typically used for heavy-duty applications, while screws are versatile and can be used in multiple construction projects. Nails are commonly used for fastening wood materials, and rivets are frequently used to join metal components together. Each type of steel fastener has its own unique characteristics and uses, ensuring that construction projects are secure and durable.

- Q: How is steel used in the manufacturing of packaging materials?

- Steel is commonly used in the manufacturing of packaging materials due to its strength, durability, and versatility. It is often used to create cans, containers, and drums for packaging various goods like food, beverages, and chemicals. Steel packaging provides excellent protection against moisture, light, and contaminants, ensuring the safety and preservation of the packaged products. Additionally, steel is recyclable, making it an eco-friendly choice for packaging materials.

- Q: What are the common uses of steel angles?

- Steel angles are commonly used in construction and engineering applications. They are often used as structural supports, providing stability and strength to various structures such as buildings, bridges, and towers. Steel angles are also used in the fabrication of frames, brackets, and reinforcements for machinery and equipment. Additionally, they are frequently utilized in the manufacturing of furniture, shelving units, and other metal-based products.

- Q: How are steel products used in the manufacturing of furniture?

- Steel products are commonly used in the manufacturing of furniture to provide structural support, durability, and aesthetic appeal. Steel is often used in the construction of chair frames, table legs, and cabinet components, as it offers strength and stability. Additionally, steel can be shaped and formed into various designs and finishes, allowing for versatile and modern furniture designs.

- Q: What are the different types of steel wire ropes and their uses in offshore drilling operations?

- There are several types of steel wire ropes commonly used in offshore drilling operations. These include drilling lines, sandline cables, and guy wires. Drilling lines are heavy-duty wire ropes designed to support the weight of the drill string and transport drilling fluids. They are used to lower and raise the drill bit, as well as to rotate the drill string during drilling operations. Sandline cables, on the other hand, are lighter wire ropes used for well servicing and workover operations. They are primarily used to lower and retrieve equipment, such as pumps and tools, into and out of the wellbore. Lastly, guy wires are steel wire ropes used to support and stabilize offshore drilling platforms or structures. They help to counterbalance the weight and forces acting on the structure, ensuring stability and safety. Overall, steel wire ropes play a crucial role in offshore drilling operations, providing strength, durability, and reliability necessary for various tasks and applications.

Send your message to us

Home Appliance Applied CRCA

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords