High Strength Silicone Coated Fiberglass Mesh Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000m2 m²

- Supply Capability:

- 1000000M2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

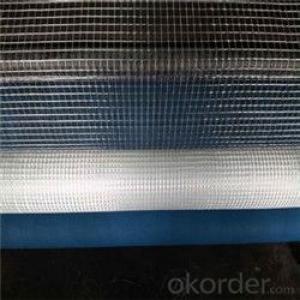

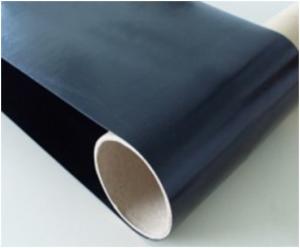

Introduction of Silicone Coated Fiberglass Fabric:

Fiberglass fabric with silicone rubber coated is produced with high quality fiberglass base cloth then impregnated or coated single side or both sides with a specially compounded silicone rubber. It is a new composite material with good performance and multiple applications.

Properties of Silicone Coated Fiberglass Fabric:

1. Good performance on resisting high temperature and low temperature, -70℃-280℃;

2. High strength;

3 .Ozone, oxide, light and weather aging resistance;

4. High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5. Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Applications of Silicone Coated Fiberglass Fabric:

1. Electric insulation: can made into insulated fabric, sleeves, and used in places which need high electric insulation grade.

2. Non-metallic compensator: used as pipeline flexible coupling, non-metallic compensator. Mainly used in power station, petroleum, chemical engineering, cement, iron and steel and so on.

3. Anti-corrosion sector: used as external and internal corrosion proofing layer of pipeline and preservation jar, It is an ideal corrosion-proofing material.

4. Fire-proofing sector: can be used in automobile making, shipbuilding industry as fire-proof fabric.

5.Others: it can also be used as construction sealing material, high temperature corrosion-proofing belt, packing material, new energy etc.

Main specification of Silicone Coated Fiberglass Fabric:

1, Thickness: 0.15mm-5mm

2. Width: 1.0-1.5m

3. Weight: 150g/m2-2800g/m2

4. Coating: single side or double sides silicone or one side silicone, other side PTFE.

5. Color: grey, black, red, white, sliver

- Q: How do you paste the mesh cloth on the back of the stone?

- This is only for those of the plate (plate - not for the world) and cut out of the finished product, there is no side treatment.

- Q: What's the use of fiberglass mesh?

- Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q: Where is fiberglass mesh better?

- Quality and import gap is not large, but prices are significantly lower. If you do not take the price into consideration, it must be the best of the imports.

- Q: How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q: The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- The building often causes the perineum to warm up and contract cold and cause cracks. Reduce the service life, glass fiber mesh cloth can be the maximum restraint to reduce such adverse effects. The glass fiber mesh cloth is insulated and used in the outer part of the main structure so as to save indoor space. It is effective enough for indoor use

- Q: Method for sampling alkali proof glass fiber mesh cloth

- The amount of cement, sand barrels after weighing pour the mixture iron grey trough, mix according to the mixture ratio and binder is added for mixing, stirring to be uniform, to avoid segregation, a gruel. Water can be added according to workability.

- Q: What is the function of the wall cloth mesh?

- The main uses are widely used:1) wall reinforcement materials (such as glass fiber wall, net cloth, GRC wallboard, EPS internal and external wall insulation board, gypsum board and so on.2) reinforce cement products (such as Rome column, flue, etc.).3) granite, mosaics, special mesh, marble back net.4) waterproof coiled material and bituminous roof waterproof.5) strengthen the skeleton material of plastic and rubber products.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- Now, many sites are pure in the transfer problem of various types of work, if the base treatment bends up, after the winter freeze will soon fall, you can put the case to the party to write a material, as long as you don't sign the party a no problem.

- Q: What harm does fiberglass mesh have to people?

- Into the digestive system, may cause digestive diseases.

- Q: Can indoor glass fiber mesh cloth be stuck with wall tiles?

- Yes, glass fiber mesh is used for roofing, waterproofing and gypsum, marble, mosaic and other wall or plate reinforcement.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI,NINGBO |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

High Strength Silicone Coated Fiberglass Mesh Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000m2 m²

- Supply Capability:

- 1000000M2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords