High Strength A Quality Fiberglass Mesh Cloth 160g 4x4 Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Fiberglass Flooring Mesh Description:

Fiberglass Flooring Mesh is mainly alkali-resistant fiberglass fabric, it use the C/E-glass fiber yam(main ingredient is a silicate,good chemical stability) through a special weaving techniq ,then by the antialkali and reinforcing agent etc high temperature heat finishing treatments. It's ideal engineering material inconstruction and decoration industry!

2.Main Features of Fiberglass Flooring Mesh:

·High manufacturing accuracy

·High strength

·Good visual effect

·Factory-direct price

·Quality assured

·20years export experience

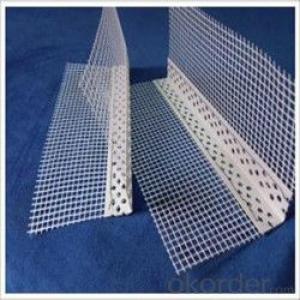

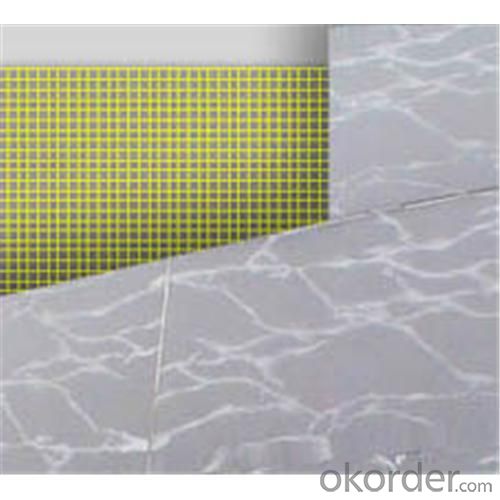

·3.Fiberglass Flooring Mesh Images

4.Fiberglass Flooring Mesh Specification

fiberglass mesh Specifications | Roll size | |||

Aperture size(mm) | Weight/ square meter | Width | Length | |

3mm x 3mm | 45g-300g/m2 | 0.2m to 4m | 30m to 300m | |

4mm x 4mm | ||||

5mm x 5mm | ||||

6mm x 6mm | ||||

7mm x 7mm | ||||

8mm x 8mm | ||||

9mm x 9mm | ||||

Packing1: shrink plastic film then woven bag. | Package2:plastic film, then in carton box | |||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What's the use of fiberglass mesh?

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion. Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings.

- Q: The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- When the heat of the interior passes through the wall mesh, the insulation will be cut off and retained, and when the room temperature falls. The wall of the heat will be released, by adjusting the indoor temperature; in the summer, glass fiber mesh insulation would block the sun's radiation and external heat into the room, so that the indoor situation of "cool", and the ten seasons and pleasant residential Polygonatum and physical skills improved significantly

- Q: Glass fiber mesh fabric quality, hard and soft for wall, which is better?

- Used on the wall, of course, is more good glue, can increase the degree of alkali resistance. Now there's one kind of urine gum, it's really hard to paint. But there is no alkali resistance.

- Q: Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- Now, many sites are pure in the transfer problem of various types of work, if the base treatment bends up, after the winter freeze will soon fall, you can put the case to the party to write a material, as long as you don't sign the party a no problem.

- Q: Can fiberglass mesh waste be recycled? What can you do if you can?

- Glass fiber mesh cloth is flame retardant products, the core material is glass fiber yarn production is completed, so has the recovery effect, which is proved that the glass fiber environmental protection that, during the two days trip I found some problems, the mesh is scrap cut, some are everywhere a throw, some is burned, there is a direct classification.

- Q: What harm does fiberglass mesh have to people?

- Inhalation of respiratory tract causing lung damage. Three

- Q: Self-adhesive fiberglass mesh

- Self adhesive mesh and EPS mesh than the general viscous grid has the characteristics and general mesh fabric. But than the general mesh more viscous soft, moderate viscosity, uniform coating, adhesive does not appear in some places, some places less adhesive at the time of construction, to avoid the "bulge" phenomenon.

- Q: Self making method and formula of glass fiber mesh cloth shaping glue

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings.

- Q: What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- Standard: to strengthen the material function and alkali fiberglass mesh cloth to external wall thermal insulation layer, the main role is: to improve the mechanical strength of the surface layer, ensure the continuity of the surface layer resistance, shrinkage pressure and insulation dispersed surface layer stress, avoid stress concentration, surface resistance nature temperature and humidity changes and accidents caused by the impact of the cracking. Therefore, alkali resistant glass fiber mesh fabric plays an important role in the external insulation system, so the selection of good glass fiber mesh fabric is also an important component to ensure the comprehensive quality of the external insulation system. The current national standard technology of exterior insulation (JG149-2003): glass fiber warp and weft resistance tensile strength shall not be less than 750N/50mm, alkali resistant tensile strength retention rate of not less than 50%, more than 130 grams of weight per square meter.

- Q: What is the quota of alkali resistant fiberglass mesh cloth sleeve?

- 5 thick wall plastering mortar is pressed into the middle layer of alkali resistant glass fiber mesh, 03 quota is not suitable to apply the quota items, should set their own preparation of the quota items.

Send your message to us

High Strength A Quality Fiberglass Mesh Cloth 160g 4x4 Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords