Fiberglass Mesh With High Quality Good Price 160G

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

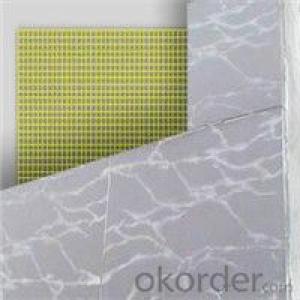

1.Structure of Fiberglass Mesh Description:

Our fiberglass mesh have good grid fixity, and high strength, good adhesion with cement mortar, excellent fitting positioning, excellent alkali resistanceis very prominent, resistant to high alkaline substances concrete erosion. Strength retention rate> 90%, elongation <1%, the durability of more than 50 years. High elastic modulus 80.4Gpa, is can't reach by other chemical fibers.

2.Main Features of Fiberglass Mesh:

High manufacturing accuracy

High strength

Good visual effect

Factory-direct price

Quality assured

20years export experience

3.Fiberglass Mesh Images

4.Fiberglass Mesh Specification

Item Number | Yarm (tex) | Mesh Size | Density Count/625px | Finished Weight(g/m2) | Tensile StrengthX500px | Woven Structure | Content of resin% (≥) | ||||

Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | ||||

TP5x5-70 | 45x2 | 200 | 5 | 5 | 5 | 5 | 70 | 550 | 850 | Leno | 16 |

TP5x5-80 | 67x2 | 200 | 5 | 5 | 5 | 5 | 80 | 700 | 850 | Leno | 16 |

TP5x5-90 | 67x2 | 250 | 5 | 5 | 5 | 5 | 90 | 700 | 1050 | Leno | 16 |

TP5x5-110 | 100x2 | 250 | 5 | 5 | 5 | 5 | 110 | 800 | 1050 | Leno | 16 |

TP5x5-125 | 134x2 | 250 | 5 | 5 | 5 | 5 | 125 | 1200 | 1300 | Leno | 16 |

TP5x5-135 | 134x2 | 300 | 5 | 5 | 5 | 5 | 135 | 1300 | 1400 | Leno | 16 |

TP4x4-135 | 100x2 | 250 | 4 | 4 | 6 | 6 | 135 | 1000 | 1300 | Leno | 16 |

TP5x5-145 | 134x2 | 360 | 5 | 5 | 5 | 5 | 145 | 1200 | 1300 | Leno | 16 |

TP4x5-150 | 134x2 | 300 | 4 | 5 | 6 | 5 | 150 | 1300 | 1300 | Leno | 16 |

TP5x5-160 | 134x2 | 400 | 5 | 5 | 5 | 5 | 160 | 1450 | 1600 | Leno | 16 |

TP4x4-160 | 134x2 | 300 | 4 | 4 | 6 | 6 | 160 | 1550 | 1650 | Leno | 16 |

TP4x5-165 | 134x2 | 350 | 4 | 5 | 6 | 5 | 165 | 1300 | 1300 | Leno | 16 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Can fiberglass mesh waste be recycled? What can you do if you can?

- Mesh cloth, such as discarded cloth, is not corrosive and may not corrode for hundreds of years, causing serious pollution to the land;

- Q:Where are the steel wire mesh and the alkali resistant grid cloth used in the exterior wall insulation?

- Two different wall plastering joints, to play a role in cracking; generally in the amount of graphics can be directly in the report to see the amount of engineering;Wire mesh and mesh cloth each have their own uses! Specific to see your design drawings.

- Q:Method for sampling alkali proof glass fiber mesh cloth

- The polymer mortar ratio is: KL binder: 425# sulphoaluminate cement: sand (with 18 mesh screen bottom),:=1:1.88:3.25 (weight ratio).

- Q:What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- The difference lies in the degree of use of alkali resistant glass fiber, at present there are very few domestic high alkali glass fiber products, the difference is in the base. Because the glass itself is not alkali resistant, so in the processing of glass fiber products add alkali resistant components, adding two zirconia, the glass fiber has certain effect on tolerance -OH.The mesh fabric produced with alkali resistant glass fiber is alkali resistant grid cloth, and the others are the same

- Q:Glass fiber mesh cloth bent do to straighten it?

- Can be divided into gold pot and earthen pot, the general earthen pot product soft and hard to control, because the surface of the pot products are generally coated with urine glue, gold pan surface coated with emulsion, quality is good, control some. Soil pot products only two kinds of hard and soft state, one is hard, then the product is slightly, but the texture is brittle, the tensile resistance is not good, it is easy to break ninety percent off, a state is soft, this product is pulling resistance is large, but not so on the location, soil pot coated urine glue products, soft and positioning the product is contradictory, hard, good positioning effect, small tensile strength, soft, poor positioning effect, large force.

- Q:Self-adhesive fiberglass mesh

- Self adhesive mesh and EPS mesh than the general viscous grid has the characteristics and general mesh fabric. But than the general mesh more viscous soft, moderate viscosity, uniform coating, adhesive does not appear in some places, some places less adhesive at the time of construction, to avoid the "bulge" phenomenon.

- Q:Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- Acrylic emulsion less water, that is, high cost. It's cheap and good

- Q:What's the use of fiberglass mesh?

- Glass fiber mesh cloth with alkali resistant fiberglass mesh, it uses alkali free glass fiber yarn (the main ingredient is silicate, good chemical stability) by structure leno weaving and special organization, after the anti alkali, heat setting treatment such as reinforcing agent.

- Q:What is the function of the wall cloth mesh?

- Wall mesh, also called glass fiber wall mesh, with alkali or alkali glass fiber yarn, woven glass fiber mesh to the substrate, and then a new alkali resistant products coated with acrylic copolymer solution after drying into.

- Q:What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- The interior powder is usually used at the joint of the wall (there is a mesh fabric specially used for joint, called adhesive tape or joint tape)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Mesh With High Quality Good Price 160G

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords