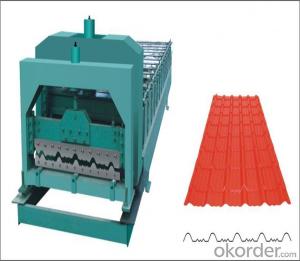

High Speed Trapezoidal sheets Roll Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Trapezoidal sheets Roll Forming Machine

Technical data of Trapezoidal sheets Roll Forming Machine

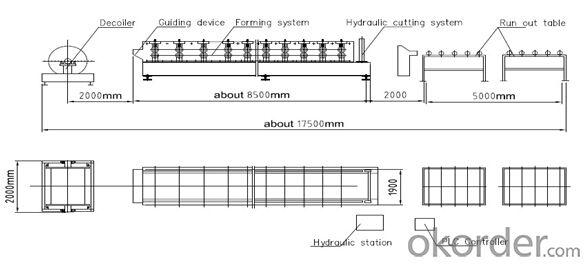

Suitable Material | Q235 color steel sheet;0.3-0.7mm, 1000&1250mm coil width | |

Working speed | About 20m/min | |

Power Requirement | Main motor power: 7.5 Kw(Depend on final design) | |

Hydraulic station power: 2.2Kw(Depend on final design) | ||

Material of forming rollers | No.45 steel, plated with chrome on surface. | |

Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 | |

Shaft diameter | 72mm | |

Controlling system | Mitsubishi PLC & converter | |

Total weight of machine | About 8500KGS | |

Machine''''s size | About 15m×1.8m× 1.5m (Depend on final design) | |

Shipping | 1x40GP container can load one machine | |

Layout drawing of Trapezoidal sheets roll forming machine

Our Trapezoidal sheets Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines. |

- Q: Method for compiling model of metal cutting machine

- Lathes, Drilling Machines, Boring Machines, Grinding Machines, Gear Machining Machines, Thread Machining Machines, Milling Machines, Planers, Broaching Machines, Electric Machining, Machine Tools, Cutting Machines, Machine Tools, Other Machine Tools.

- Q: Say that China's machine is not good, then they are sold to whom?

- In the basic processing, domestic machine tools have a higher price.

- Q: What is the machine tool ah I would like to ask what is the use of CNC machine tools

- Machine tool points are many, you said the CNC machine tools should be said that CNC lathes,

- Q: How many kinds of machine tools

- These machines are suitable for single-piece, small batch and multi-species and part processing, with good processing size consistency, high productivity and degree of automation, and high equipment flexibility. Metal forming CNC machine tools; such machine tools, including CNC bending machines, CNC combination punch

- Q: What is the meaning of CNC machining?

- , Can save production preparation time;

- Q: What is the main work of CNC machine tools?

- , high precision machining 3, processing stable and reliable, to achieve computer control, excluding human error, parts of the processing of good consistency, stable and reliable quality.

- Q: What is the role of a CNC machine lock switch?

- The control system can logically process a program with control codes or other symbolic instructions and decode it, digitally represented by code, and input to the numerical control device through the information carrier.

- Q: How is the system number defined in machine tool classification?

- Category Lathes Drilling Machines Boring Machines Grinding Machines Gear Machining Machines Thread Machining Machines Milling Machines Planers Punching Machines Broaching Machines Special Machining Machines Sawing Machines Other Lathes

- Q: The lathe belongs to the machine? The machine? Other production equipment? The equipment related to the production activity? What kind of classification?

- A single plan can simplify your fixed assets, especially if your company is more careful in calculating the cost of production. The term "machine" is too general, and the production equipment is mainly for the first production line, the direct production of machinery,

- Q: What lathes are lathes?

- CNC transformation, a variety of CNC machine tools for the design and manufacture

Send your message to us

High Speed Trapezoidal sheets Roll Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches