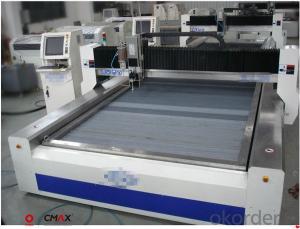

Stud and Track Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

|

Stud & track forming machine

Product of Stud & track forming machine

Technical data of Stud & track forming machine

Suitable Material | Cold-rolled steel strip and heat-treated galvanized steel strip | |

Thickness of raw material | 0.5-0.6mm (235-345Mpa) | |

Material of roller | 45# steel being quenched treatment | |

Material of cutter blade& punching die | Cr12 mould steel being quenched treatment,HRC58-60 | |

Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. | |

Forming speed | About 20m/min | |

Power Requirement | Main motor power: 5.5 Kw(Depend on final design) | |

Hydraulic station power: 5.5Kw (Depend on final design) | ||

Diameter of shaft for rollers | 55mm | |

Controlling system | Mitsubishi PLC & converter | |

Quantity of rollers | About 15 stations for main rollers | |

Weight of machine | About 6500KGS | |

Size of machine installation | About 15m x 1.7m x 1.4m | |

Our Roll Forming Machine’s advantages

| 1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard chrome . 2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation. 3. Cutter blade: Cr12 mould steel with quenched treatment, long life time. 4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance. 5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction. 6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifttime services for our machines |

- Q: Say that China's machine is not good, then they are sold to whom?

- But into the field of precision machining, domestic machine tool precision level and degree of automation than imported machine tools or no small gap.

- Q: The Function of Machine Tool Body in CNC Machine Tool

- Its function is to support the mechanical parts and components of the body, and to ensure that these parts industry in the cutting process in the exact location.

- Q: CNC lathe price

- Tell the truth is very weak competitiveness.

- Q: The difference between the lathes 6140, 6240

- In the lathe can also be used drill, reaming drill, reamer, tap, die and knurling tools such as the corresponding processing.

- Q: In the machine practice, only allow a student to operate alone, other students should do

- In the machine practice, only allow a student to operate alone

- Q: What is the meaning of CNC machining?

- CNC (CNC machine) is a computer numerical control machine (Computer numerical control) for short, is a program controlled by the automation machine. The control system can logically control the code or other symbols with the provisions of the procedures, through the computer to its

- Q: What can a CNC lathe do?

- There are many kinds of CNC lathes, economical and practical and high precision.

- Q: Who can tell me the difference between instrument lathe and CNC lathe

- Therefore, the CNC lathe is currently using a wider range of machine tools.

- Q: How is the system number defined in machine tool classification?

- Category Lathes Drilling Machines Boring Machines Grinding Machines Gear Machining Machines Thread Machining Machines Milling Machines Planers Punching Machines Broaching Machines Special Machining Machines Sawing Machines Other Lathes

- Q: Other types of CNC machine tools for what occasions?

- CNC machine tools can be divided into two categories: built-in and independent type

Send your message to us

Stud and Track Forming Machine with ISO Quality System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 15 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords