High Speed Beer Filling and Sealing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

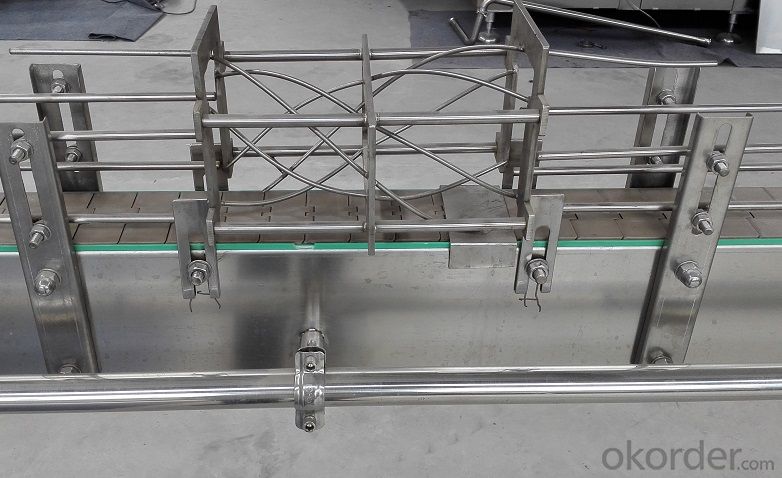

Beer Can Filling and Sealing Machine

This production line is suitable for the production of all kinds of carbonated drinks contained in aluminum 2-piece pop-top can, such as cola, aerated water, ice tea, etc, It is an ideal machine for small-and medium-sized beverage factories.

Descriptions:

1. This filling machine is used for filling carbonated beverage in cans , such as beer, cola, energy drinks and soda water.

2. This beverage can filling machine can be used for different material of cans, such as plastic, iron, aluminum and so on ,and the different size of cans is allowed.We can design the euipment according to your requirements

3. This beverage can filling machine is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry.

4. The can filling machine is a pop canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit.

5. Filling and sealing is the overall designed, power system by filling sealing system to Ensure that both the absolute synchronization and coordination.

6. Beverage can filling machine adopts the advanced machine, electrical equipment, and Pneumatic control technology.

7. The beverage can filling machine has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss.

Rotary type 2 in 1

| Model | Unit | GDF12-1 | GDF18-6 | GDF24-6 |

| Capacity | Cans/h | 2000 | 5000 | 8000 |

| Power | KW | 0.75 | 3.7 | 3.7 |

| Dimension | mm | 1750*1140*1950 | 2320*1400*1900 | 2580*1675*1900 |

| Weight | KG | 1800 | 2500 | 3000 |

Linear type:

| Model | Unit | CGJ-50 | DGC-12/16 | YLG-40 |

| Capacity | Cans/h | 3000 | 1500-3500 | 2400 |

| Power | KW | 0.55 | 0.75 | 0.75 |

| Dimension | mm | 1900*530*1100 | 810*1050*2050 | 930*700&1850 |

| Weight | KG | 480 | 500 | 500 |

| Suitable can size | mm | Φ40-80 | Φ40-90, H 50-340 | Φ50-67, H 90-200 |

Rotary Type 2 in 1 Machine:

Can Rinser:

Can filling head:

can sealing head:

can inverter:

Linear Type Can Filling Production Line:

Installation, debug, training, after sales

(One.)Installation, debug

After equipments reached the workshop of customer, place the equipments

according to plane layout we offered. We will arrange seasoned technician for

equipments installation, debug and test production at the same time make the

equipments reach the rated producing capacity of the line. Time for installation and debug is 15-25 days.

(Two.)Training

Our company offer technology training to customer. The content of training is

structure and maintenance of equipments, control and operation of equipments.

Training is in the workshop of customer. Seasoned technician will guide and

establish training outline. After training, the technician of buyer could master the

operation and maintenance, could adjust the process and treat different failures.

(Three.) Quality guarantee

We promise that our goods are all new and not used. They're made of suitable

material, adopt new design. The quality, specification and function all meet the

demand of contract. We promise that the products of this line could storage for one

year without adding any aseptic.

(Four.)After sales

1,After checking, we offer 12 months as quality guarantee, free offer wearing parts

and offer other parts at the lowest price. In quality guarantee, the technician of buyers

should operate and maintain the equipments according to seller's demand, debug

some failures. If you could not solve the problems, we will guide you by phone; if the

problems are still can not solve, we will arrange technician to your factory solving the

problems. The salary is 80usd per day.

2,After quality guarantee, we offer technology support and after sales service.

Offer wearing parts and other spare parts at favorable price; after quality guarantee,

the technician of buyers should operate and maintain the equipments according to seller's

demand, debug some failures. If you could not solve the problems, we will guide you by

phone; if the problems are still can not solve, we will arrange technician to your factory

solving the problems. The salary is 80usd per day.

Check & accept of equipments

One. check & accept standard(bottles and caps should be eligible)

(1)Woring efficiency of the whole line ≥85%;

(2) The quantity of waster of the whole line <=0.2%

1) Bottle leakage: invert the bottle and press by hand come forth water leakage

2) Without cap, crooked cap or cap with damage

3) Clip bottle bad or damage the bottle seriously

(3).The whole line will run continuously for 8 hours, stable quantity of the average

acceptable-end products>=99%

(4).The distance between the material inside the bottle and the top of bottle neck is less

than 8mm (full after cooling)

(5).The liquid reflux<10%

(6).The sanitation of the product meets the standard of beverage industry.

(7).About the checking and accepting of animalcule will carry sample and check according to the standard of nation beverage industry, the result of checking will according to the request of industry standard.

Two. Check & accept procedure

(1) After debugging the machine in seller's factory, after checking out and signature of two sides, then we can shipping the machine.

(2) Finish installation and debugging the machine, after checking out, Running the whole production line to show the line function, after certification then final checking. Meanwhile training for operation, maintenance and so on, then make a signature of two sides to become effective.

- Q: What are the main functions of packaging machinery?

- The main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Sometimes, this wine packaging PigHead, with different types of vacuum packaging machine

- Q: Color code positioning of packaging machinery

- The use of the printed color packaging materials, photoelectric switch (available on the color electric eye tracking and positioning), through the control system to drive the stepper motor rotation and color according to the distance between the automatic stop, to complete and accurate packaging products logo.

- Q: The role of packaging equipment in packaging equipment

- Some products, such as food and drug packaging, according to the health law is not allowed to use manual packaging, because it will pollute the products and packaging machinery to avoid direct contact with the staff of food and medicine, to ensure the quality of health.(8) it can promote the development of related industriesPackaging machinery is a comprehensive science which is related to many subjects, materials, process and equipment, electronics, electrical appliances, automatic control and other related disciplines, requires the simultaneous and coordinated development, any discipline problems will affect the overall performance of packaging machinery. Therefore, the development of packaging machinery will effectively promote the progress of related disciplines. In addition, in order to meet the needs of high-speed packaging machinery packaging, the relevant front and rear processes are bound to adapt, and also promote the simultaneous development of related processes.

- Q: What's the best place to use the pillow type packing machine?

- Suggest that manufacturers can find communication, there is no technical strength,

- Q: Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q: Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;But to use the hot pressing machine there is to do bakelite mold. Our company specializing in the production of blister, in addition to help customers hot packaging, directly to the finished products to customers

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- This is really not sure, it can be said that any group, as long as the packaging products are required to use packaging machinery. Most of the products are now in need of packing. So it can be said that any group.

- Q: What are the structures of the packaging machinery?

- Is a company engaged in outsourcing clients, packaging, processing, packaging equipment, leasing, services, sales in one of the specialized companiesSales of second-hand packing equipment according to the customer's product features and requirements. Reduce customer purchasing costsAccording to the customer's product characteristics and requirements. Select the best packaging equipment for customers, reduce customer purchasing costsPackaging equipment spare parts sales and maintenance services

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Can be used to shape complex products. The principle is similar to that of injection molding. One is used for thermosetting, heating and cooling in molds, one for thermoplastic, and the other for heating in the barrel and molding cooling in the mold.

Send your message to us

High Speed Beer Filling and Sealing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords