High Silica Ceramic Fiberglass Casting Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

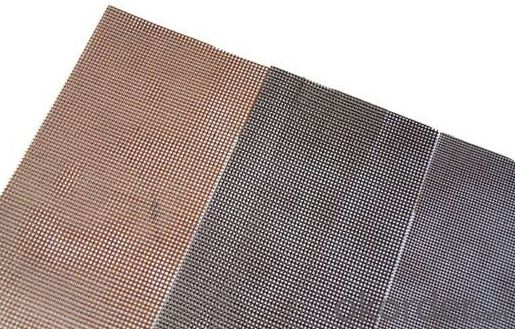

High silica fiberglass casting filter

high silica mesh casting filter can effectively remove slag,refractory particles and non-metallic inclusions from molten metals.It is developed as a low cost but with rather filtration efficiency

alternative to ceramic filters.Made from specially treated silica yarns,silica mesh filters are capable of

withstanding pouring temperatures up to 1620 Degree C.Silica mesh filters are ideal for in-mold filtration of gray, malleable,white,compacted graphite and ductile cast irons, as well as non-ferrous

aluminum and copper-based metal alloys and many types of small scale steel casting filtration.

ADVANTAGES:

• Low cost and easy to use

• Improves fluidity and metal distribution

• Removes micron sized inclusions and impurities

• Can be used with existing pattern equipment

• Eliminates inclusions created by ceramic chips

APPLICATIONS:

• Cut pieces for in mold filtration like sand casting,gravity casting,etc.

• Cut pieces for riser sleeves,bottom or across ports in walls

• Cut pieces to provide a weakened plane for riser knock-off

• Cup shapes for investment casting

SPECIFICATION:

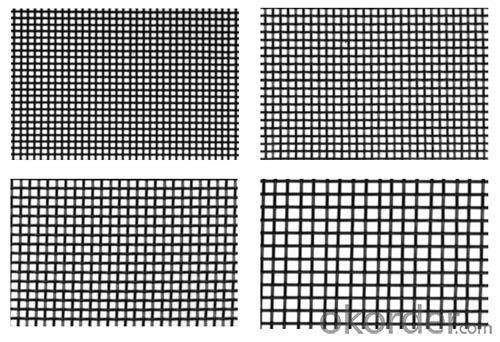

Model No. | SiO2% | Thickness | Mesh size | Max.Temp. | Open area | Max.work time |

HSFG-15 | ≥96 | 0.35mm | 1.5x1.5mm | 1450℃ | 55% | 10minutes |

HSFG-20 | ≥96 | 0.35mm | 2.0x2.0mm | 1450℃ | 60% | 10minutes |

HSFG-25 | ≥96 | 0.35mm | 2.5x2.5mm | 1450℃ | 70% | 10minutes |

HSFG-S15 | ≥96 | 0.98mm | 1.5x1.5mm | 1620℃ | 22% | 15seconds |

HSFG-S20 | ≥96 | 0.98mm | 2.0x2.0mm | 1620℃ | 26% | 15seconds |

HSFG-S25 | ≥96 | 0.98mm | 2.5x2.5mm | 1620℃ | 32% | 15seconds |

FILTERING TIPS:

• Copper alloys&leaded bronze:1.5x1.5mm mesh

• Gray Iron:1.5x1.5mm mesh

• Ductile Iron:2.0x2.0mm &2.5x2.5mm mesh

• Small scale steel:1.5x1.5mm mesh

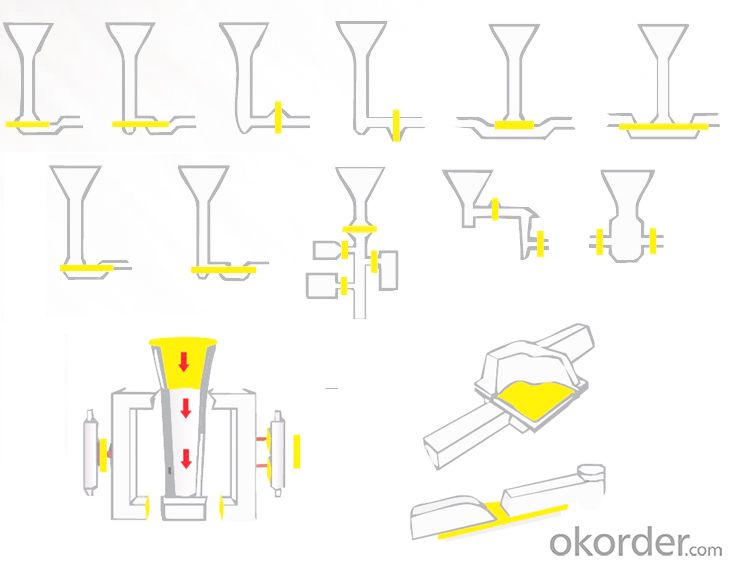

PLACEMENT POSITION:

*Cut pieces can be rectangular or round,size from 20mm to 900mm.

*Preformed cup filter OD can be 100/110/115/120mm or as per request.

- Q: Is the filter plate of the ceramic filter afraid of freezing?

- The filter plate of ceramic filter is afraid of frost and should be protected.

- Q: Working principle, ultrasonic trouble and troubleshooting of ceramic filter

- Ceramic filter is mainly composed of system, roller system, mixing discharge system, vacuum system, liquid discharge system, scraper system, washing system, cleaning system, automatic control system, and these parts body frame.

- Q: What are the poor filtration effects of vacuum disc filters?

- Under normal circumstances, high vacuum, vacuum suction, high production capacity, filter cake moisture control is good. At present, some ceramic filters are equipped with two or multi-stage vacuum system to obtain almost absolute vacuum, and can reach 0.09 ~ 0.098MPa.

- Q: Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- Ceramic filter plate.The ceramic filter plate does not match the blockage or selection of new plate porosity is generally around 40%, such as ceramic filter plate has hole blocking, the opening rate will become less, when the suction effect into 30% relatively new plate may be slightly worse, when the ceramic filter plate is used for a long time after the opening rate is 10% or less, then the ceramic filter plate suction effect will become very poor even suction. At this time, even if the vacuum suction is good, also do not suck sizing, you need to replace the new ceramic filter board.

- Q: What are the materials that make up the ceramic mold?

- From the development trend of rice, the development of ceramic membrane preparation technology mainly in the following 2 aspects: one is the porous membrane research, to further improve the already commercialized inorganic ultrafiltration and microfiltration membrane, nanofiltration membrane with molecular sieve, the development function of gas separation membrane and pervaporation membrane: two in dense membrane research solid electrolyte membrane, ultra-thin metal and its alloy film and ion conduction ability is research hotspot. The commercial porous membranes are mainly ultrafiltration and microfiltration membranes, and their preparation methods are mainly particle sintering and sol-gel. The former is mainly used for making microporous filter membranes, and commercial A1203 films are prepared by particle sintering method.

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- The faster the speed is, the shorter the time required for each turn, i.e., the shorter the filtration time, the less the filtrate will be

- Q: The working principle of ceramic filter

- The working principle and mechanism and the shape of ceramic filter disk vacuum filter is similar to that in the pressure under the action of suspension by filtration medium, particles are trapped cake is formed at the surface of the medium, and the liquid through a filter medium outflow, reached the purpose of solid-liquid separation. The difference is that the filter medium of ceramic filter plate with microporous capillary effect, the capillary force in the pores is larger than the vacuum force applied to microporous keep full liquid state, no matter under what circumstances, the ceramic filter plate does not allow air through, because there is no air through solid-liquid separation, low energy consumption, vacuum a high degree of.

- Q: Common troubles of ceramic filter

- (1) low vacuum, can not meet the production requirements. The main reason is the vacuum pipeline leakage, vacuum pump circulating water is not enough, vacuum pump impeller wear and tear, distribution head wear, ceramic filter plate damage, filtrate tank drainage valve is not closed, pulp trough material level is lower;(2) low or fluctuating backwash water pressure. The main reason is the blockage or leakage of the backwash water pipe system and the distribution of head wear;(3) the liquid level of the filtrate tank is high. The main reason is that the circulating water pump impeller or pump shell wear, pressure is insufficient, so that the drain valve can not open or drain valve itself failure, and filter barrels and circulating water pipe between the leakage;

- Q: Does the ceramic factory use hydrochloric acid?

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

Send your message to us

High Silica Ceramic Fiberglass Casting Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches