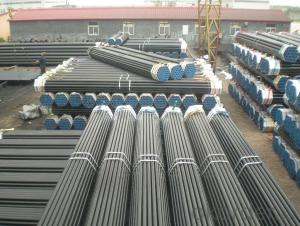

High Quality Seamless Steel Tubes For Hydraulic Pillar Service

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Seamless Steel Tubes for Hydraulic Pillar Service

Standard:

1.Carbon steel pipe: ASTM A106,A53, ASTM A179, ASTM A192,DIN17175 ST45.8 ST35.8

2.Alloy steel pipe: ASTM A335,ASTM A213

3.Stainless steel pipe: ASTM A312,ASTM A213

4.Line pipe and cashing pipe: API5L ,API 5CT

Out Diameter:

1/8 – 30 inch (10.3-762mm)

Wall Thickness:

0.049” – 2.5” (1.24- 63.5mm)

Length:

Random Length, Fixed Length, SRL, DRL

Steel Grade:

API 5L: GR B, X42, X46, X56, X60, X65, X70

ASTM A53/A106: GR A, GR B, GR C

ASME SA106: GR.A, GR.B, GR.C

ASME SA192: SA192

ASME SA209M: T1, T1a

ASME SA210: GR.A-1, GR.C

ASME SA213: T2, T5, T9, T11, T12, T22

ASME SA335: P2, P5, P9, P11, P12, P22, P91

DIN17175:ST35.8, ST45.8, 15Mo3, 13CrMo44

Usage/Application of High Quality Seamless Steel Tubes for Hydraulic Pillar Service

Applicable to the general structure, mechanical structure, Low, medium and high pressure boiler,

transportation for gas, water, oil and natural gas, tubes for heat exchanger and chemical fertilizer

equipments, for hydraul hydraulic pillar service etc..

- Q: Can steel pipes be used for underground culverts?

- Yes, steel pipes can be used for underground culverts. Steel pipes are known for their strength, durability, and resistance to various environmental factors, which makes them suitable for underground applications. They can withstand heavy loads, high water pressure, and the corrosive effects of soil and water. Additionally, steel pipes are available in various sizes and thicknesses, allowing for customization to fit specific project requirements. However, it is important to consider factors such as the soil conditions, water table levels, and potential for corrosion when selecting the appropriate type of steel and protective coatings for the pipes.

- Q: What are the common methods for repairing steel pipes?

- Some common methods for repairing steel pipes include welding, pipe wrapping, pipe relining, and pipe bursting.

- Q: What does "SC50" steel pipe mean in civil engineering?

- In the production of T-shape welded steel pipe, the wrong edges happen frequently, and the influence factors are many. In production practice, steel pipe degradation is often caused by dry, wrong and side errors. Therefore, it is necessary to analyze the causes and preventive measures of spiral steel tubes.

- Q: How are steel pipes used in stadium construction?

- Steel pipes are commonly used in stadium construction for various purposes such as structural support, roofing, and plumbing systems. They provide strength and durability to the overall structure of the stadium, allowing it to withstand heavy loads and adverse weather conditions. Steel pipes are also used for the installation of HVAC systems, water supply lines, and drainage systems within the stadium.

- Q: Can steel pipes be used for food processing facilities?

- Yes, steel pipes can be used for food processing facilities. Steel pipes are commonly used in food processing facilities due to their durability, strength, and resistance to corrosion. They are also easy to clean, which is essential in maintaining proper hygiene standards in food processing environments. Additionally, steel pipes can withstand high temperatures and pressure, making them suitable for various food processing applications such as conveying liquids, gases, and solids. However, it is important to ensure that the steel pipes used in food processing facilities are made from materials that are approved for contact with food, and that they are regularly inspected and maintained to prevent any contamination risks.

- Q: What is the maximum pressure that steel pipes can withstand?

- The maximum pressure that steel pipes can withstand depends on various factors such as the pipe's diameter, thickness, quality, and intended application. However, steel pipes are known for their high strength and durability, allowing them to withstand significant pressure.

- Q: How do steel pipes perform in earthquake-prone regions?

- Steel pipes perform well in earthquake-prone regions due to their high strength, durability, and flexibility. The inherent properties of steel, such as its ability to absorb energy and distribute stress, make steel pipes resistant to seismic activity. Additionally, steel pipes can be designed and installed with specific measures to further enhance their seismic performance, ensuring the safety and reliability of infrastructure in earthquake-prone areas.

- Q: Can steel pipes be used for underground air supply systems?

- Yes, steel pipes can be used for underground air supply systems. Steel pipes are often used in underground applications due to their strength, durability, and resistance to external factors such as corrosion and impact. They can withstand the pressure and temperature requirements of air supply systems and can be easily installed underground. Additionally, steel pipes have a long lifespan, making them a cost-effective choice for underground air supply systems. However, it is important to consider factors such as soil conditions, potential for corrosion, and local regulations when selecting the appropriate steel pipes for the specific underground air supply system.

- Q: How do you calculate the thermal expansion of steel pipes?

- To calculate the thermal expansion of steel pipes, you need to know the coefficient of thermal expansion (CTE) of the specific type of steel used. This value represents how much the steel material expands or contracts per unit length with each degree of temperature change. Once you have the CTE, you can multiply it by the initial length of the steel pipe and the temperature change to determine the thermal expansion. The formula is: Thermal Expansion = CTE x Initial Length x Temperature Change.

- Q: Are steel pipes suitable for underground irrigation systems?

- Yes, steel pipes can be suitable for underground irrigation systems. Steel pipes are known for their durability and strength, making them resistant to corrosion and able to withstand high pressure. They are also less likely to crack or break under the ground's weight or pressure. Additionally, steel pipes have a long lifespan, reducing the need for frequent replacements. However, it is important to consider the type of water being transported, as certain minerals or chemicals in the water can cause corrosion over time. In such cases, it may be necessary to use corrosion-resistant coatings or liners. Overall, steel pipes are a reliable choice for underground irrigation systems, especially in areas with high water pressure or where durability is a priority.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2001 |

| Annual Output Value | 800,000Tons |

| Main Markets | Europe and the United States; Canada; India; South etc. |

| Company Certifications | API 5L; API 5CT; GB/T19001-2000 idt ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao; Lianyungang |

| Export Percentage | 50% - 60% |

| No.of Employees in Trade Department | 1000-1100 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | Above 423,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Seamless Steel Tubes For Hydraulic Pillar Service

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords