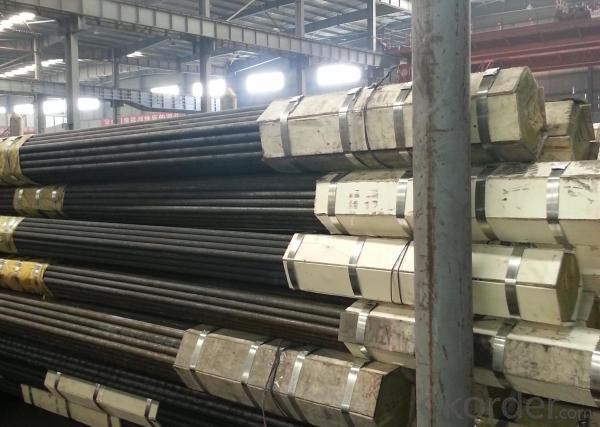

High Quality Seamless Medium-carbon Steel Tubes For Boilers And Superheaters

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality Seamless Medium-carbon Steel Tubes For Boilers And Superheaters:

| ||||||||||||||||||||||||||||||||||||||

Usage/Application of High Quality Seamless Medium-carbon Steel Tubes For Boilers And Superheaters:

It can be used for transmitting a large number of fluid. Such as oil, natural gas, water and some solid materials. At the same time it can be widely used as the manufacture of various structural parts and mechanical parts, as well as building construction.

Packaging/Delivery of High Quality Seamless Medium-carbon Steel Tubes For Boilers And Superheaters:

Wrapped in bundles with steel strips or according to customers' requirements

- Q: What is the dimensional stability of steel pipes?

- The ability of steel pipes to retain their shape and dimensions in different conditions and external forces is referred to as dimensional stability. Steel pipes are well-known for their exceptional dimensional stability due to the inherent properties of the material. Steel, being a strong and rigid material, can maintain its shape even when subjected to high pressure or temperature fluctuations. This characteristic makes steel pipes highly suitable for applications that demand stability and resistance to deformation, such as plumbing, oil and gas pipelines, and structural supports. In addition to its inherent strength, the dimensional stability of steel pipes is also a result of their manufacturing processes. These pipes are typically produced using methods like seamless or welded construction, ensuring uniformity and consistent dimensions throughout the pipe's length. This precise manufacturing contributes to the dimensional stability of steel pipes. Furthermore, steel pipes are often coated with various protective coatings to increase their resistance to environmental factors. These coatings, such as galvanization or epoxy coatings, not only provide corrosion protection but also enhance the dimensional stability of the pipes by adding an extra layer of strength and durability. In conclusion, the widespread use of steel pipes in different industries is largely attributed to their dimensional stability. Their ability to maintain their shape and dimensions, even in challenging conditions, guarantees reliable and long-lasting performance in various applications.

- Q: What does GALV mean in a steel tube?

- Steel pipe is not only used to transport fluid and powder solid, exchange heat energy, and manufacture mechanical parts and containers, but also is an economic steel. It can reduce weight and save 20 to 40% of metal by using steel pipe to make building structure, network frame, prop and mechanical support. Moreover, it can realize factory mechanization construction. Using steel pipe to manufacture road bridge can not only save steel, simplify construction, but also greatly reduce the area of coating protective layer, save investment and maintenance cost.

- Q: What is the average lifespan of steel pipes in different applications?

- The average lifespan of steel pipes in different applications can vary significantly depending on factors such as the type of application, the environment it is exposed to, and the level of maintenance. However, in general, steel pipes can last anywhere from 20 to 100 years or more, making them a durable and reliable choice for various industries and infrastructure projects.

- Q: What are the different types of steel pipe connections for oil and gas pipelines?

- There are several types of steel pipe connections used for oil and gas pipelines, including threaded connections, welded connections, flanged connections, and grooved connections. Threaded connections involve screwing two pipe ends together using threads, providing a secure and leak-proof joint. Welded connections involve fusing pipe ends together using heat, creating a strong and durable joint. Flanged connections use a flange on each pipe end that is bolted together, providing a sturdy and easily removable joint. Grooved connections involve utilizing a groove on each pipe end, which is then locked together using a coupling, ensuring a reliable and flexible joint.

- Q: The difference between 12Cr1MoVG alloy steel tube and 15CrMo

- 12Cr1MoVG is a kind of material for alloy tubes. The main purpose is to make the steel structure in the boiler, the use temperature of 580 degrees, requiring high temperature resistance steel plate, durable strength, steel plate in the normalized and tempered state delivery. 12Cr1MoV alloy tube is based on high quality carbon structural steel. It is appropriate to add one or more alloy elements to improve the mechanical properties, toughness and hardenability of steel.

- Q: What is the maximum allowable deflection for steel pipes?

- The maximum allowable deflection for steel pipes depends on various factors such as pipe diameter, wall thickness, material strength, and the intended application. It is typically determined by industry standards and specific engineering considerations.

- Q: What are the common problems or issues faced with steel pipes?

- Common problems or issues faced with steel pipes include corrosion, leakage, cracking, and scaling. Corrosion can occur due to exposure to moisture, chemicals, or environmental factors, leading to reduced structural integrity and potential leaks. Leakage can result from faulty welds, damaged seals, or pipe degradation. Cracking can occur due to excessive stress, temperature fluctuations, or manufacturing defects, compromising the pipe's strength. Scaling or buildup of mineral deposits can also restrict flow and affect performance. Regular inspection, maintenance, and proper coating or lining can help mitigate these issues.

- Q: Difference between seamless steel pipe and welded pipe

- Welded steel pipe for different welding process and divided into the furnace pipe welding (ERW) pipe and automatic arc welding, because of the different forms of welding seam welded pipe and spiral welded pipe is divided into two kinds, end its shape is divided into circular welded and shaped (square) pipe etc..

- Q: Can steel pipes be used for underground power transmission?

- Yes, steel pipes can be used for underground power transmission. Steel pipes are commonly used for underground power transmission due to their durability, strength, and resistance to corrosion. They provide a reliable and secure conduit for transmitting power underground while protecting the electrical cables from external elements.

- Q: What is the difference between steel pipes and cast iron soil pipes?

- Steel pipes and cast iron soil pipes differ in their composition and characteristics. Steel pipes are made of an alloy of iron and carbon, providing them with high strength and durability. They are commonly used for transporting fluids and gases, and are resistant to corrosion. On the other hand, cast iron soil pipes are made from molten iron that is poured into molds. They are primarily used for drainage and sewage systems due to their excellent soundproofing properties. Cast iron soil pipes are more resistant to fire and have a longer lifespan compared to steel pipes. Additionally, cast iron soil pipes are typically heavier and thicker than steel pipes, making them more suitable for underground installations. However, steel pipes are lighter and easier to handle, making them a preferred choice for above-ground applications. Ultimately, the choice between steel pipes and cast iron soil pipes depends on the specific requirements of the project, such as the intended use, location, and budget.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2005 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | 390People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM not offered |

| Product Price Range | Average |

Send your message to us

High Quality Seamless Medium-carbon Steel Tubes For Boilers And Superheaters

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15M.T. m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords