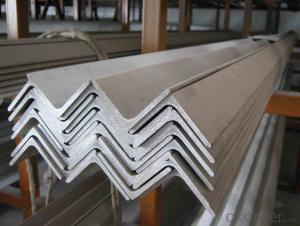

high quality equal angle ATM A36

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ROUND BAR Details:

| Minimum Order Quantity: | | Unit: | m.t. | Loading Port: | |

| Supply Ability: | | Payment Terms: | | Package: | wire bundle |

Product Description:

Specifications of Wire Rod Q235:

Steel Grade: Q235, Standard: GB Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Diameter Tolerance:±0.3mm 6.5mm can be drawing into 2mm/8.0mm can be drawing into 3mm

Brand Name: N-RIVER Place of Origin: Hebei, China Mainland Application: construction, building etc

Chemical Composition:

Please kindly find our chemistry of our material based on Q235 as below for your information

Trademark | Rank | Chemical composition (quality score) % | | ||||

C | Si | Mn | S | P | | ||

| | |||||||

| ≤ |

| ≤ | ≤ | | ||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | | ||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | | ||||

| | |||||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | | |||||

≤16 | 16-40 | | ≤16 | 16-40 | | ||

≥ | | ≥ | | ||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

Usage and Applications of Wire Rod Q235:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Packaging & Delivery of Wire Rod Q235:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

- Q: What is the typical shear strength of steel angles?

- The typical shear strength of steel angles can vary depending on several factors such as the grade of steel, the size and shape of the angle, and the specific application or industry standards being followed. However, in general, steel angles are known for their high shear strength. For standard structural steel angles, the shear strength can range from approximately 50,000 pounds per square inch (psi) to 75,000 psi. This range applies to common steel grades such as A36, A572, and A588. These angles are commonly used in construction, infrastructure, and engineering projects where shear forces are a concern. It is important to note that the shear strength of steel angles can be influenced by other factors such as the presence of holes or notches, welding or fabrication processes, and the overall design and load distribution. Therefore, it is crucial to consult relevant design codes or engineering specifications to determine the specific shear strength requirements for a given application. It is also recommended to consult with a structural engineer or experienced professional to ensure the accurate determination of shear strength for steel angles in a particular project.

- Q: Can steel angles be used in the construction of industrial platforms?

- Yes, steel angles can definitely be used in the construction of industrial platforms. Steel angles are commonly used in construction projects due to their high strength and durability. These angles can be easily welded or bolted together to create a strong and stable platform structure. They are particularly useful in industrial settings where heavy loads and constant foot traffic are expected. Steel angles provide support and stability to the platform, ensuring it can withstand the weight and movement of equipment, machinery, and workers. Additionally, steel angles are resistant to corrosion, making them suitable for use in various environments, including industrial settings where exposure to chemicals, moisture, and extreme temperatures is common. Overall, steel angles are a reliable and cost-effective choice for constructing industrial platforms.

- Q: Can steel angles be used in the construction of shopping malls?

- Shopping malls can indeed incorporate steel angles in their construction. These versatile structural components offer support and stability to different parts of a building, such as shopping malls. The construction industry often employs steel angles for framing, bracing, and reinforcing structures. Their usage extends to supporting the walls, roof, and floors of shopping malls, thereby guaranteeing the building's structural integrity. Moreover, they come in handy when constructing staircases, escalators, and mezzanines within the shopping mall. The inclusion of steel angles in shopping mall construction presents numerous benefits, including their durability, strength, and cost-effectiveness.

- Q: Can steel angles be used for mezzanines or catwalks?

- Yes, steel angles can be used for mezzanines or catwalks. Steel angles are popular for these applications due to their strength and versatility. They provide structural support and can be easily bolted or welded together to create a sturdy framework for mezzanines or catwalks. Additionally, steel angles are available in various sizes and thicknesses, allowing for customization to meet specific design requirements. Overall, steel angles are a cost-effective and reliable choice for constructing mezzanines or catwalks in both commercial and industrial settings.

- Q: Can steel angles be used for temporary structures or scaffolding?

- Yes, steel angles can be used for temporary structures or scaffolding. Steel angles are often utilized in construction projects for their strength and durability. They are commonly used to provide structural support and stability in temporary structures and scaffolding systems. Steel angles are versatile and can be easily welded, bolted, or fastened together to create a sturdy and safe temporary structure or scaffolding setup. Additionally, the availability of different sizes and thicknesses makes steel angles suitable for various temporary construction applications.

- Q: Can steel angles be used for staircases or handrails?

- Yes, steel angles can be used for staircases or handrails. Steel angles provide structural support and can be used to create sturdy and durable staircases and handrails. They are commonly used in construction for their strength and versatility.

- Q: How do you calculate the bending capacity of a steel angle?

- In order to determine the bending capacity of a steel angle, several factors must be considered. The initial step involves calculating the moment of inertia (I) of the angle section, which measures its resistance to bending. The moment of inertia relies on the angle's shape and dimensions, and can be found in the manufacturer's specifications or through calculations. Once the moment of inertia has been obtained, the section modulus (Z) can be calculated as another indicator of the section's ability to resist bending. The section modulus is found by dividing the moment of inertia by the distance from the centroid of the section to the extreme fiber. Subsequently, it is necessary to establish the maximum allowable bending stress (σ) for the steel angle. This value is typically provided by the manufacturer or can be determined based on the desired safety factor and the type of steel being used. Lastly, the bending capacity (M) of the steel angle can be calculated by utilizing the formula M = σ * Z. This calculation provides the maximum moment that the angle can endure without experiencing excessive bending stress. It is important to note that these calculations assume the angle's behavior is elastic and do not account for additional factors such as local buckling, residual stresses, or combined loading. Therefore, it is advisable to consult relevant design codes or guidelines for a more comprehensive analysis to ensure the safety and reliability of the steel angle in a specific application.

- Q: Is there a screw that can be made like angle iron, but not a right angle, just a single piece of material? That's the way to break the angle iron in two. What if it's called? Thank you, professionals!

- As for the cutting of wood cutting machine can cut metal with no blade, you can find a corner grinder to cut angle grinder specifications you can use with 100 or 125 with the same diameter, diameter, cutting slice thickness 3mm, slice should be perpendicular to the cutting piece.

- Q: Are steel angles prone to warping or twisting?

- Steel angles exhibit a general resistance to warping or twisting, making them highly suitable for a range of structural and manufacturing applications due to their exceptional strength and stability. The production of steel angles involves a hot-rolling process, where the steel billet is heated to a high temperature and then molded into the desired angle shape. This manufacturing technique guarantees that the angles retain their shape and structural integrity. Nevertheless, it is worth noting that steel angles can potentially warp or twist under extreme heat or stress conditions. This is more likely to occur when the angles are exposed to high temperatures, uneven heating or cooling, excessive loads, or improper installation. In such instances, the angles may suffer a compromise in their integrity, resulting in deformation. To minimize the risk of warping or twisting, it is essential to adhere to proper handling and installation procedures. This includes ensuring an even distribution of loads and avoiding prolonged exposure to excessive heat. Moreover, it is advisable to utilize high-quality steel angles from reputable manufacturers and conduct routine inspections to promptly identify and prevent any potential issues. In conclusion, although steel angles generally exhibit resistance to warping or twisting, it is imperative to consider the specific conditions and factors that may impact their stability. Taking appropriate measures to ensure their long-term structural integrity is vital.

- Q: Are steel angles suitable for supporting countertops?

- Yes, steel angles are suitable for supporting countertops. Steel angles are strong, durable, and can provide excellent support for countertops, making them a popular choice in many construction and kitchen design projects.

Send your message to us

high quality equal angle ATM A36

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords