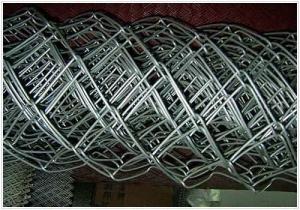

High Quality Chain Link Fence Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | Application: | Agriculture field, sport field, tennis | ||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Material: | Surface treatment: | Roll Length: | |||

| Mesh/Opening: | Color: |

Packaging & Delivery

| Packaging Detail: | 1.woven bags of the above and bottom,high quality package or as customes requested 2.In roll ,water proof paper in side and our side with weave bag;carton;wooden case;pallet. 3. according to customers requirement. |

Galvanized Chain Link Fence | |||||

wire diameter mm | mesh size mm | roll length m | standard netting heights mm | standard post heights mm | |

1 | 5×5 | 10 | 500 | 1000 | |

1000 | 1500 | ||||

1.2 | 10×10 | 10 | 1250 | 2000 | |

20×20 | 1500 | 2000 | |||

1.4 | 20×20 | 10 | 2000 | 2500 | |

1.8 | 30×30 | 10 | 2500 | 3000 | |

2.5 | 40×40 | 10 | 3000 | 3500 | |

2.8 | 50×50 | 10 | 4000 | 4500 | |

3 | 50×50 | 10 | 5000 | 5500 | |

4 | 60×60 | 10 | 5000 | 5500 | |

|

|

|

|

| |

PVC Coated Chain Link Fence | |||||

Wire diameter mm | mesh size mm | roll length m | standard netting heights mm | standard post heights mm | |

1.8 | 20×20 | 10 | 500 | 1000 | |

1000 | 1500 | ||||

1250 | 2000 | ||||

1500 | 2000 | ||||

1.8 | 30×30 | 10 | 2000 | 2500 | |

2.5 | 40×40 | 10 | 2500 | 3000 | |

2.8 | 50×50 | 10 | 3000 | 3500 | |

3 | 60×60 | 10 | 4000 | 4500 | |

4.5 | 65×65 | 10 | 5000 | 5500 | |

- Q: Can steel wire mesh be used as a decorative element?

- Yes, steel wire mesh can be used as a decorative element. It offers a modern and industrial aesthetic and can be used in various applications such as wall panels, room dividers, ceilings, and furniture. Its versatility and durability make it a popular choice for adding a unique and visually appealing touch to interior and exterior spaces.

- Q: How does the thickness of the steel wire affect the strength of the mesh?

- The thickness of the steel wire plays a significant role in determining the strength of the mesh. Generally, a thicker wire will result in a stronger mesh. This is because a thicker wire has a higher cross-sectional area, which allows it to withstand greater forces and resist deformation or breakage. A thicker wire also provides more stability and rigidity to the mesh structure, making it more resistant to bending, stretching, or sagging. This is especially important in applications where the mesh is subjected to heavy loads or impacts, as a thicker wire can better distribute and absorb the forces, preventing the mesh from failing. Furthermore, a thicker wire can enhance the durability and longevity of the mesh. It is less prone to wear and tear, corrosion, or damage from external factors. This is particularly crucial in harsh environments or outdoor settings, where the mesh is exposed to moisture, chemicals, or extreme temperatures. However, it is important to note that the thickness of the wire should be chosen considering the specific requirements of the application. Using an excessively thick wire may lead to unnecessary weight and cost, while a wire that is too thin might compromise the strength and integrity of the mesh. Therefore, a careful balance between the wire thickness and the intended use of the mesh needs to be achieved to ensure optimal strength and performance.

- Q: Is steel wire mesh resistant to wear and tear?

- Indeed, steel wire mesh exhibits exceptional resistance to wear and tear. Its design is specifically tailored to endure harsh conditions and extensive usage. Comprised of resilient and sturdy steel wires interwoven or welded together, this mesh forms a durable and enduring substance. It finds wide application in areas such as fencing, construction, industrial equipment, and filtration systems, all of which subject it to continual motion, pressure, and abrasion. Given its inherent robustness and durability, steel wire mesh serves as an optimal selection for applications necessitating a trustworthy and enduring material.

- Q: What are the standard dimensions of steel wire mesh panels?

- The standard dimensions of steel wire mesh panels can vary depending on the specific application and industry requirements. However, there are some commonly used standard dimensions that can provide a general idea. For architectural and decorative purposes, steel wire mesh panels typically come in standard sizes of 4 feet by 8 feet (1.2 meters by 2.4 meters) or 5 feet by 10 feet (1.5 meters by 3 meters). These dimensions are often used for applications such as wall cladding, ceiling panels, and railing infill. In industrial applications, steel wire mesh panels are often available in larger sizes to accommodate larger structures and machinery. These panels can range from 6 feet by 12 feet (1.8 meters by 3.6 meters) to 8 feet by 20 feet (2.4 meters by 6 meters) or even larger. These larger dimensions are commonly used for applications such as fencing, security enclosures, and machine guarding. It is important to note that these dimensions are just general standards, and custom sizes can also be manufactured to meet specific project requirements. Additionally, the wire diameter and opening size of the mesh panels can vary based on the intended use and desired level of strength or visibility. Therefore, it is advisable to consult with manufacturers or suppliers to determine the best dimensions for a particular application.

- Q: How is steel wire mesh used in the automotive industry?

- Steel wire mesh is used in the automotive industry for various purposes. It is commonly used in the construction of car grilles and radiator covers to provide protection and ventilation. Additionally, it is used as reinforcement in car seats to enhance comfort and durability. Steel wire mesh is also utilized for reinforcing the body structure and chassis components of vehicles, ensuring strength and safety.

- Q: Is steel wire mesh suitable for use in automotive airbag systems?

- No, steel wire mesh is not suitable for use in automotive airbag systems. Airbag systems require materials that are lightweight, flexible, and have high tensile strength. Steel wire mesh is heavy, rigid, and may not provide the necessary level of flexibility required for airbags to properly deploy and protect occupants in the event of a collision. Additionally, steel wire mesh may not offer the same level of impact absorption as other materials used in airbag systems, potentially compromising the safety of the vehicle occupants. Therefore, alternative materials such as nylon or polyester fabric are commonly used in automotive airbag systems due to their lightweight, flexible, and high tensile strength properties.

- Q: How does the edge finish affect the installation process of steel wire mesh?

- The edge finish of steel wire mesh can greatly impact the installation process. A smooth and clean edge finish allows for easier handling and manipulation of the mesh during installation. It reduces the risk of injuries or damage to the mesh or surrounding structures. On the other hand, a rough or jagged edge finish can make it more challenging to align and secure the mesh properly, potentially leading to uneven or unstable installation. Therefore, a good edge finish is crucial for a smooth and efficient installation process of steel wire mesh.

- Q: Is steel wire mesh suitable for packaging applications?

- Yes, steel wire mesh is suitable for packaging applications. Steel wire mesh offers several advantages that make it a suitable choice for packaging. Firstly, it provides excellent strength and durability, ensuring that the packaged items are well-protected during transportation and handling. The robust nature of steel wire mesh makes it resistant to tears, punctures, and abrasions, reducing the risk of damage to the packaged goods. Additionally, steel wire mesh allows for proper ventilation and visibility. This is particularly important for certain types of products that require airflow or need to be easily identifiable. The open design of the mesh allows air to circulate freely, preventing the build-up of moisture and ensuring the freshness of perishable items. Moreover, the transparency of the mesh enables easy identification and inspection of the packaged goods without the need for opening or unwrapping. Furthermore, steel wire mesh is reusable and recyclable, making it an environmentally friendly packaging option. The durability and longevity of steel wire mesh allow it to be reused multiple times, reducing the need for frequent replacement. Moreover, at the end of its life cycle, steel wire mesh can be easily recycled, contributing to waste reduction and sustainability efforts. In conclusion, steel wire mesh is a suitable material for packaging applications due to its strength, durability, ventilation, visibility, and environmental benefits. It offers a practical solution for protecting and transporting various types of products, making it a preferred choice for many packaging needs.

- Q: Can steel wire mesh be used for bird cages?

- Yes, steel wire mesh can be used for bird cages. Steel wire mesh is a durable and strong material that provides a secure enclosure for birds. It is commonly used in the construction of bird cages due to its ability to withstand the pecking and scratching of birds. The small gaps in the mesh prevent birds from escaping, while still allowing for proper ventilation and visibility. Additionally, steel wire mesh is easy to clean and maintain, making it a practical choice for bird cage construction.

- Q: How is steel wire mesh used in reinforcement of embankments?

- Steel wire mesh is commonly used in the reinforcement of embankments to provide stability and prevent erosion. The mesh is typically placed within the embankment structure to distribute the load and improve its overall strength. When constructing embankments, such as those found in roadways, railways, or retaining walls, steel wire mesh is often incorporated as a reinforcement measure. The mesh is made up of interlocking strands of steel wire, forming a grid-like pattern. This grid acts as a reinforcement layer that enhances the embankment's resistance to external forces, such as the weight of the soil, water pressure, or ground movements. The main function of steel wire mesh in embankment reinforcement is to distribute the load more evenly across the structure. By providing a continuous network of interconnected wires, the mesh helps to transfer the load from the surface to the underlying layers, reducing the risk of localized failures or deformations. This is especially important in areas with weak or unstable soils, where the mesh can help to stabilize the embankment and prevent settlement or collapse. Additionally, steel wire mesh can also serve as a barrier against erosion. It helps to retain the soil particles within the embankment, preventing them from being washed away by water or wind. This is particularly crucial in embankments located near rivers, streams, or coastal areas, where the risk of erosion is higher. The use of steel wire mesh in embankment reinforcement offers several advantages. It is a cost-effective solution compared to alternative methods, such as using concrete or geosynthetic materials. Steel wire mesh is also relatively easy to install and can be customized to fit the specific requirements of the embankment project. Furthermore, its durability and resistance to corrosion ensure a long lifespan, providing long-term stability and protection to the embankment structure. In conclusion, steel wire mesh plays a crucial role in the reinforcement of embankments. It enhances the embankment's strength, stability, and resistance to external forces, while also preventing erosion. Its cost-effectiveness, ease of installation, and durability make it a preferred choice for many embankment construction projects.

Send your message to us

High Quality Chain Link Fence Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords