High Alumina Brick - High Quality Best Price Insulated Refractory Fire Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shaanxi, China (Mainland) | Shape: | Brick | Material: | Alumina Cement |

| SiO2 Content (%): | 0.1~1.4% | Al2O3 Content (%): | 48%-85% | MgO Content (%): | 0.1~1.4% |

| CaO Content (%): | 0.01 | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 0.1~0.3% |

| SiC Content (%): | 0.1~1.4% | Model Number: | DFL-LZ | Brand Name: | CNBM |

| size: | LZ-85, 80, 70, 65, 55, 48 | apparent porosity: | 23% Max | refractoriness: | 1750℃ Min |

| refractoriness under load: | 1420℃ Min | cold crashing strength: | 35 MPa Min | Al2O3: | 48% Min |

| thermal shock resistence: | 4-10 | reheating linear change: | 1450℃x2 +0.1 -0.4 | experience: | over than 15 years |

| quality system: | ISO9001-2008 |

Packaging & Delivery

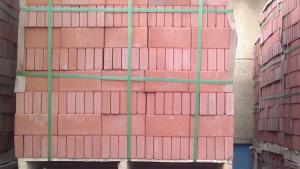

| Packaging Details: | in pallet for sea ship |

| Delivery Detail: | 15-45 days after get customers's deposit |

High alumina bricks

description

Specifications of high alumina bricks

1. AL2O3 : 45%-80%.

2. Can according to customers' requirements.

3. Used for steel ladle lining.

High alumina steel ladle fire brick,Steel ladle brick,Ladle brick

Application of high alumina bricks

High alumina brick is widely used for Widely used in blast furnaces, Hot Blast Stove, Steel ladle lining, Reheating furnace, Cement kiln,Tunnel kiln,boiler, coke oven, carbon furnace,glass kiln , Steel smelting furnace and various kiln lining and thermal technical equipment, etc.

Features of high alumina bricks

1) High-temperature endurable .

2) Good thermal shock resistance .

3) Good resistance to abrasion and corrosion.

4) Good thermal shock and thermal spalling resistance.

5) High mechanical strength.

6) Good volume stability at high temperature.

Physical and chemical index of high alumina bricks

Item | Specification | ||||||

LZ-85 | LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 | 85 | 80 | 75 | 65 | 55 | 48 | |

Apparent density | 23 | 22 | 23 | 23 | 22 | 22 | |

Cold crushing strength | 65 | 55 | 50 | 45 | 40 | 35 | |

RUL | 1600 | 1530 | 1520 | 1500 | 1450 | 1420 | |

PLC | 1500.C*2h | 0.1~-0.4 | |||||

1450.C*2h | 0.1~-0.4 | ||||||

Standards of Type Brick:

| 230mmx114mmx65mm

Product Range: SK32,SK34,SK35,SK36,SK37,SK38

| ||||||

Specail Shape of High Alumina Brick

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- The difference between the two kinds of high alumina bricks is great. I perennial in Zhengzhou was responsible for the production and sale of colt refractories

- Q: What are the high aluminum bricks made of?

- The amount of refractory mud accounts for about 6% of the brick weight

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- The chemical pH value of high alumina refractory brick belongs to neutral and alkaline refractory brick, and clay refractory brick belongs to neutral and acid refractory brick.

- Q: What is the content of free silica in the refractory bricks of high alumina bricks?

- Refractory powders are not rich in free silica in varying degrees

- Q: What are the characteristics of high alumina bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined.

- Q: Are there any differences between insulating bricks and refractory bricks?

- Heat preservation brick is to emphasize its heat preservation performance generally, not paying much attention to its refractoriness, but refractory brick is exactly the opposite. Different locations will use different materials, I hope we can choose carefully.

- Q: How to distinguish the good or bad of the high aluminum brick?

- In the procurement of high alumina brick, the first color, high quality aluminum brick, brick surface smooth, yellow color pale, four sides equal, no broken angle, no cracks.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- When the high alumina brick is used at high temperature, the physical and chemical indexes and other constants will not change if the temperature is in the physical and chemical indexes and the softening temperature of the load.

Send your message to us

High Alumina Brick - High Quality Best Price Insulated Refractory Fire Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 8000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords