High Purity White Fused Corundum for Grinding Wheels - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

white fused corundum

1.professional manufacture

2.abrasive raw mateirials for grinding whehels

3.free samples are gurantee

Packaging & DeliveryPackaging

Details:a. in 25kg plastic woven bags.

b. In 1000kg big bag.

c. 40 x 25kg plastic woven bags in one big bag.

d. 40 x 25kg plastic woven bags on pallet.

e. 40 x 25kg paper bags on pallet.

Delivery Detail:15days after received the ordet

white fused corundum for grinding wheels

White Fused alumina is smeltin in aelectrical arc furnace from aluminum oxide powder.The colour is white,the hardness and toughtness is a little higher than brown aluminum oxide.

TYPE WAE-17M

This kind of white fused aluminium oxide grain has sharp shape and medium bulk density, can be used for different grinding abrasives applications.

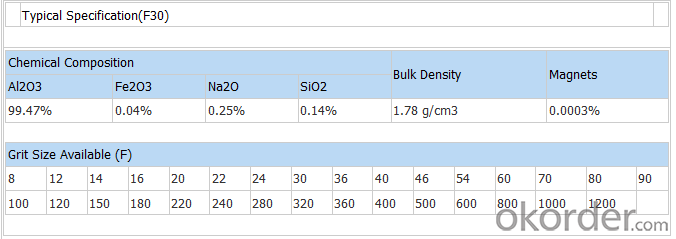

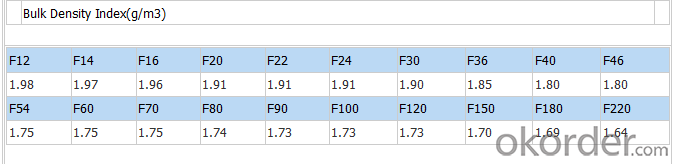

Size Distribution:According to FEPA-Standard 42-1984 R 1993.

- Q: Can anyone tell me what material the first rate fire resistant door is?

- Class A fire door materials are mainly steel, wood, steel and wood,and other materials. If there is filling material in a Class A fire door, it is generally the perlite. According to the actual situation in China, the fire doors and windows are divided into class A, class B, class C, whose minimum fire endurances are stipulated, namely class A 1.50h, class B 1.00h, Class C 0.50h. There are fireproof wooden doors and fireproof steel doors. whose main purpose is to achieve fire endurance time. But door closers are required to be installed.

- Q: What is the upper temperature limit for refractory materials?

- Different materials are different. In the professional field, there is a triangulation cone softening point experiment as a reference for using the upper temperature limit.

- Q: How long is the duration of fire resistance of autoclaved flyash-lime bricks?

- The compressive strength of the autoclaved flyash-lime bricks is generally higher, which can reach 20MPa or 15MPa, at least 10MPa, and it can withstand the 15 freeze-thaw cycles. Besides,fly ash brick is a kind of potential active hydraulic material. In the humid environment, it can continue to produce hydration reaction and make the internal structure of the brick is more dense, which is conducive to improvement of the strength. It is found in experiments and many investigations that sample some carbide which is used for foundation, plinth and drains, after one or twenty years of freezing thawing and wetting drying, some bricks have been completely carbonized, but strength is not reduced, increased instead. This is one of the merit of autoclaved flyash-lime bricks.

- Q: How to make fire resistant materials for building stoves

- Why Qianjun game protected mode can attack the foreign baby call

- Q: Does anyone know which materials belong to light fire resistant material?

- Fire partitions can be divided into organic and inorganic fire partitions, the main ingredient of organic fire partitions is organic material, which can be used for cable tray with corrosion-resistant and fire protection requirements, and the main ingredient of inorganic fire partitions is inorganic material, mainly used for fire protection. As the main component is inorganic material, it can not be use in projects with acid-resistant and alkali-resistant requirements. Of course, the price of the same amount of organic fire partitions is generally more expensive than that of the inorganic fire partitions . The fire endurance of these two products of general enterprises are 3 hours.

- Q: Which fire-resistant materials have good viscidity?

- The viscidity of fire-resistant materials is also known as the binding performance of fire-resistant materials. It can be divided into chamotte and chemical binder. Both can work at normal or high temperature. The most commonly used chamotte are soft clay and aluminate cement. The commonly used chemical binders include sodium silicate, phosphoric acid, aluminum sulphate, aluminium phosphate, phenolic resin, etc. Fire resistant material is a complicated and overloaded system and we cannot know its materials and chemical components from the name alone. Both gunning mix and repair mix contain binder components. If they can used after adding water, then they may contain clay or fire resistan aluminum silicate cement.

- Q: What are the main components of refractory cement?

- Refractory cement, also known as aluminate cement, can also be gray. Aluminate cement is often yellow or brown. Aluminate cement takes bauxite and limestone as raw materials, alumina content of about 50% as the clinker. And it is a hydraulic cementing material made by grinding. The main mineral of aluminate cement is mono calcium aluminate (CaO · Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO · SiO2), etc.

- Q: What are the disadvantages of the refractory industry?

- The rapid development of continuous casting technology allows Hua Heng refractories to be improved in variety and quality. The development of refractory for continuous casting has a significant impact on the production of continuous casting and quality of continuous casting billet. Constructing and putting Baosteel into action has greatly pushed the improvement of the refractory technology. Continuous casting refractory is an important part of the continuous casting machine. In addition to the general characteristics of refractories, it is also required functions that can purify molten steel, improve the quality of steel, stabilize temperature and composition of the molten steel, control and regulate the molten steel flow. Therefore, it is known as functional refractories. Continuous casting Refractories include: (1) ladle refractory - ladle lining, permanent lining and ventilation components; (2) tundish refractories - permanent lining, coating, insulating plates, clad etc; (3 ) functional refractories - long nozzle for non-oxidizing casting, submerged nozzle, monolithic stopper, sliding gate; (4) ceramic purifier for purifying molten , slag dam, alkaline paint and horizontal separating ring and gate board for continuous casting.

- Q: How to divide fire resistant level of fire door?

- The classification of fire resistant level of fire door: Grade A is not less than 1.2h. Grade B is not less than 0.9h. Grade C is not less than 0.6h. It is suitable for fire door with different levels: Grade A: Equipment room (such as fire-pump room,power distribution room, generator room, smoke control fan room, etc) door, fire?compartment, door on firewall; Grade B: Eclosed staircase, front door of stair room, smoke-proof?staircase and fire elevator share lobby door, front door of fire elevator, household door which directly opens to front room or shares room; Grade C: The vertical shaft door, such as strong electric wells, weak electric wells, pipe shaft door and air conditioning facilities. I hope this information can help you.

Send your message to us

High Purity White Fused Corundum for Grinding Wheels - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords