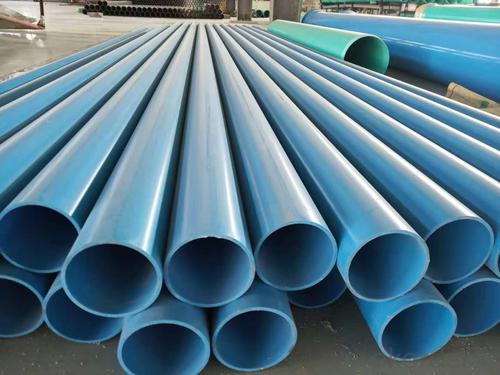

High-performance hard polyvinyl chloride (PVC-UH) water supply pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PVC-UH water supply pipe is made by improving the molecular chain structure of PVC, so that the product has high strength, high pressure, ring rigidity, good internal and external pressure, suitable for paving in the pipe gallery, good toughness and high modulus. It has small shrinkage, more than 45% of ring flexible energy, good impact resistance, suitable for material stress release caused by temperature changes in the pipe gallery; built-in plastic inspection well with high pressure sealing performance to ensure piping system Sealing; easy to install and fast maintenance, low maintenance cost; pipeline system design life ≥ 50 years, with the advantages of low investment and high cost performance.

PVC-UH pipe outer diameter range: dn20mm~dn1600mm, pressure rating: 0.63MPa~2.5MPa. The standard length of the pipes is 6 meters, 9 meters, 12 meters, and the colors are blue .

The pipe connection method is divided into solvent-adhesive type, elastic sealing ring type and integral apron connection. It can also be connected to other types of pipes such as cast iron pipes by flanges or other suitable adapters.

(2) Implementation standards

CJ/T493-2016

(3) Scope of application

Water conservancy project, industrial water supply project, urban pipe network construction project

(4) Product advantages

In addition to PVC-M and PVC-U pipes, PVC-UH pipe has the following advantages: light weight, good corrosion resistance, good hydraulic performance, high mechanical strength, convenient construction, impact resistance and environmental crack resistance.

1 Reliable connection, increased integrated rubber ring connection, reducing the possibility of leakage, thus reducing maintenance costs.

2 The toughness is better, the toughness of the pipe is improved, and the adaptability to geological settlement is better.

3 Improve the mechanical properties and ensure the stability of pipeline operation.

(5) Technical requirements

Project | Technical indicators |

Density / (kg / m3) | 1350~1460 |

Vicat softening temperature / °C | ≥80 |

Longitudinal retraction rate / (%) | ≤5 |

Dichloromethane immersion test (15 ° C, 15 min) | Surface change is not inferior to 4N |

Drop hammer impact test (0 ° C) TIR / (%) | TIR≤5 |

Hydrostatic strength | No cracking, no leakage |

System suitability (connection seal test, yaw test, negative pressure test) | No cracking, no leakage |

Hygienic performance

Hygienic performance meets the requirements of GB/T 17219-1998 "Safety Evaluation Standards for Drinking Water Distribution Equipment and Protective Materials" and the Health and Safety Commission's "Standards for the Evaluation of Sanitary Safety of Drinking Water Distribution Equipment and Protective Materials".

(6)PVC pipe fittings series

PVC pipe fittings are reliable in connection, have good system sealing, better toughness and high impact resistance. The material is modified to improve the toughness of the material. High impact resistance and effective resistance to water hammer. The mechanical properties are improved, the stability of the pipeline operation is ensured, the minimum required strength of the material is improved, and the bearing strength is high.

- Q: What glue can glue rubber tube?

- The rubber hose can be made of HY-308 glue.HY-308 metal rubber glue is mainly used in various plastic, rubber, metal jewelry, electronic products, such as high products, wood products, such as rapid adhesion between each other, strong adhesion.

- Q: Plastic coated metal hose flexible conduit joint what treatment

- You see what the other end is connected to the main, if the connecting hose can be used self fixed joints, if no thread connection pipe, to set joint by three column card, if the connection device or threaded pipe, external thread joint, and some fittings, Glenn joint

- Q: Why should the high pressure hydraulic tube peel off the outer skin?

- High pressure hose is generally relatively thick, there are steel wire layer, the purpose of peeling is to connect the tooth and steel layer close combination, the joint is more solid. But not all high-pressure hose needs peeling. Now many large companies do not need peeling. For example, pike.

- Q: Does rubber hose drink from tap water? Is it poisonous?

- Galvanized steel pipe is divided into cold galvanized pipe, hot galvanized pipe, the former has been banned, and the latter is also advocated by the state for the moment, can be used. In 60s and 70s, developed countries began to develop new types of pipes, and galvanized pipes were banned. China's Ministry of construction and other four ministries have also issued a civilization, from two, 000 years since the prohibition of galvanized pipe, the current New District cold water pipe has rarely used galvanized pipe, and some of the hot water pipe is galvanized pipe.

- Q: How to distinguish the true and false corrosion resistant rubber soft joint?

- Soft joint products into your acidic medium, a bubble will know!

- Q: The main features of Linatex rubber tube or what are the characteristics?

- Linard, BB:, halogenated butyl rubber. Acid and alkali resistance, good air tightness, high temperature resistance.Linaplus, FG:, natural rubber, FDA certified, for long-term exposure to food applications.Linaplus, OZ:95% natural rubber, excellent abrasion resistance, UV resistance, and ozone performance

- Q: Must the hose for the cooker be made of oil resistant rubber hoses?

- When the gas combustion equipment and gas pipeline for hose connection, the design should meet the following requirements: (1) the burner of household gas stove and laboratory use, the connecting hose length should not exceed 2m, have no interface; (2) industrial production with mobile gas burning equipment, the connecting hose the length should not exceed 30m, the interface should not exceed 2;...

- Q: M40 and M50, and then the hose is 2 "what does the box connection mean?"

- M40 and M50 are the specifications of the teeth, but you do not specify the spacing of the teeth.

- Q: What are the gas hoses?

- The stainless steel is expensive, 40 yuan set.The rubber is cheap, 10 yuan a set.Where do you come from? I don't know. In our Shanghai gas, this price includes the labor cost of the installation to you. In other words, fix it directly for you.

- Q: What's the difference between hose and hose for compressed air?

- In use, it is usually marked with color. For example, the intake is made of blue, and the exhaust is made red, but it is not necessary.

Send your message to us

High-performance hard polyvinyl chloride (PVC-UH) water supply pipe

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 5000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords