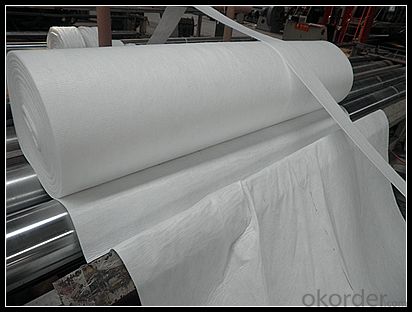

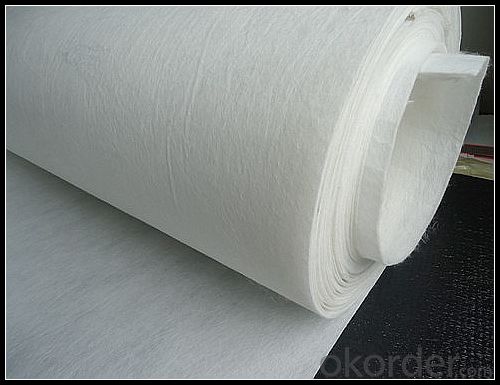

High-Performance Geotextile Grid Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

CMAX-S001

1.High strength ; low deformation.

2. Durability: steady property, not easy to resolved, airslaked and keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resist insects and mould.

4. Permeability: the woven geotextile can control the sieve size to retain permeability.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: 300g / m2 geotextile package is what it means

- 300g / m2 Geotextile: refers to the weight of 300g per square meter (model) 300g / m2 geotextile package: refers to the outsourcing; with 300g of geotextile to wrap something; for example: With 300g / m2 geotextile wrapped gravel. The

- Q: Where is the geotextile in the municipal works?

- Conservation, consideration, there is more green and more Chinese geotextile material manufacturers

- Q: How do geotextiles contribute to the stability of railroad ballast?

- Geotextiles contribute to the stability of railroad ballast by providing separation, filtration, and reinforcement functions. They act as a barrier between the ballast and underlying soil, preventing the mixing of materials and maintaining the integrity of the track system. Geotextiles also help to filter out fine particles, preventing clogging and maintaining proper drainage. Additionally, they provide reinforcement, distributing the load more evenly and reducing the potential for settlement and deformation. Overall, geotextiles enhance the stability and longevity of railroad ballast, improving the performance of the track system.

- Q: Can geotextiles be used in soil erosion control on construction sites?

- Yes, geotextiles can be used in soil erosion control on construction sites. Geotextiles are permeable fabrics that can be placed on the soil surface to prevent erosion by stabilizing the soil and allowing water to pass through while retaining sediment. They are effective in controlling erosion, reducing sediment runoff, and maintaining soil integrity during construction activities.

- Q: How do geotextiles help with soil reinforcement in soft ground conditions?

- Geotextiles provide soil reinforcement in soft ground conditions by acting as a stabilizing layer. They distribute the load evenly, increasing the soil's bearing capacity and preventing excessive settlement. Additionally, geotextiles enhance soil drainage, reduce water seepage, and prevent erosion, thereby improving the overall stability and strength of the soft ground.

- Q: Can geotextiles be used in underground storage tank installations?

- Yes, geotextiles can be used in underground storage tank installations. Geotextiles are commonly used as a protective barrier between the tank and the surrounding soil, providing filtration and separation functions. They can help prevent soil erosion, control groundwater flow, and provide additional stability to the tank system.

- Q: What is the number of tensile units for geotextiles

- Personal sense of the number of stretching units is mainly for the sparse geotextile geotextile, geotextile, geogrid or other similar loose structural materials, sample 1m width of the number of stretching units is 1m width of the number of holes or how many cells, The number of stretched units within the test is the number of holes or the number of cells in the test width. For example, geotextile geogrid 1m width of 25 holes, the number of stretching unit is 25, the sample width of 200mm with 5 holes, the number of drawing unit is 5, C = Nm / Nsc = 25/5 = 5 individuals Understanding is not necessarily advice

- Q: What are the considerations for geotextile selection in landfill projects?

- The considerations for geotextile selection in landfill projects include factors such as the required strength and durability of the geotextile, its ability to resist punctures and tearing, its compatibility with the waste material, and its resistance to chemical degradation. Other factors to consider include the geotextile's permeability, its ability to retain soil particles while allowing for proper drainage, and its cost-effectiveness. Additionally, the geotextile should be selected based on its compliance with regulatory requirements and standards for landfill construction.

- Q: How do geotextiles contribute to soil compaction control?

- Geotextiles contribute to soil compaction control by acting as a barrier between the soil and any applied loads or stresses. These textiles distribute the load more evenly, reducing the pressure on the soil and minimizing the potential for compaction. Additionally, geotextiles can improve soil stability and prevent erosion, further aiding in the control of soil compaction.

- Q: Are geotextiles resistant to fungal growth?

- Yes, geotextiles are generally resistant to fungal growth. They are designed to be durable and have low organic content, which makes them less susceptible to fungal colonization. Additionally, geotextiles are often treated with fungicides during manufacturing to provide further protection against fungal growth. However, the resistance may vary depending on the specific type and quality of geotextile used.

Send your message to us

High-Performance Geotextile Grid Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords