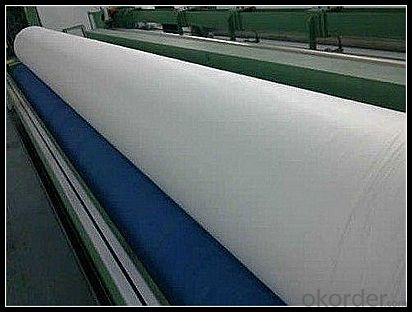

10 Oz High-Performance Monofilament Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

With firm compulsion to excellence and superiority, we have come up with a wide and quality approved assortment of Synthetic Non Woven Geotextile. Widely appreciated and acknowledged owing to their smooth texture, these are in line with quality values set by the globe. Moreover, their presence with us in a number of sizes and patterns makes these highly popular and thus demanded.

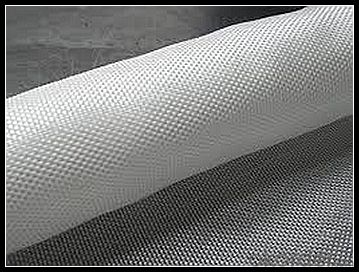

Woven and Non Woven Geotextiles are robust and durable fabrics designed to increase soil stabilization and ground support in a given location. Typically made from polypropylene fibers, these geotextiles are high in strength to allow for maximum slope support, stabilization and erosion control. Options include a felt-like nonwoven material as well as a woven polypropylene blend.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is a geotextile?

- A geotextile is a synthetic material specifically designed for use in various civil engineering and construction applications. It is typically made from polyester or polypropylene fibers and is used to stabilize soil, separate different layers of soil, and provide drainage and filtration in infrastructure projects such as roads, landfills, and retaining walls. Geotextiles are essential in preventing soil erosion, improving soil strength, and increasing the lifespan of infrastructure projects.

- Q: Is the current tunnel construction, modular waterproof board (geotextile) is available?

- Geotextiles generally do not design applications in tunnel waterproofing. Because he can not meet the requirements of tunnel waterproofing

- Q: What are the standards and regulations for geotextile products?

- The standards and regulations for geotextile products vary depending on the country and region. However, there are several widely recognized international standards that govern the manufacturing, testing, and performance requirements of geotextiles. These include standards from organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards cover aspects such as strength, durability, permeability, and environmental compatibility. Additionally, various regulatory bodies may have specific requirements for geotextile products, particularly in the construction industry, to ensure their safe and effective use in specific applications.

- Q: Are geotextiles used in landfill construction?

- Yes, geotextiles are commonly used in landfill construction. They are used as a barrier to prevent the migration of contaminants, provide drainage, and enhance stability of the landfill structure.

- Q: What is the expected lifespan of geotextiles?

- The expected lifespan of geotextiles can vary depending on various factors such as the quality of the material, the specific application it is used for, and the environment it is exposed to. However, on average, geotextiles are designed to have a lifespan ranging from 10 to 30 years.

- Q: What glue glue is used at the seams of the impervious geotextile

- What glue glue is used at the seams of the impervious geotextile

- Q: What are the different geotextile erosion control products available in the market?

- There are several geotextile erosion control products available in the market, including geotextile fabrics, erosion control blankets, turf reinforcement mats, silt fences, and sediment control tubes. These products are designed to prevent soil erosion, stabilize slopes, control sediment runoff, and promote vegetation growth.

- Q: Geotextile longitudinal and lateral elongation gap is too much how to adjust

- 1. The elongation at break of the geotextile is divided into longitudinal elongation at break and transverse elongation at break. Generally speaking, the elongation at longitudinal and transverse faults is not very different. GB GB / T-2008 standard requirements geotextile longitudinal and lateral elongation between 20% -100% are qualified. 2. Longitudinal transverse fracture elongation gap is too large, you can check the mixing hopper, carding machine is mixed evenly, combing evenly. 3. Acupuncture machine too fast or too high acupuncture may lead to geotextile longitudinal and transverse elongation gap, you can try to debug the speed of the next needle machine. 4. Appropriate to add some industrial oil can enhance the geotextile rupture strength, and elongation at break.

- Q: What are the advantages of using geotextiles in green roof systems?

- The advantages of using geotextiles in green roof systems include improved drainage, erosion control, and increased structural stability. Geotextiles help prevent soil erosion by allowing water to drain through while retaining the soil. They also provide a strong base for the green roof system, enhancing its structural integrity. Additionally, geotextiles can act as a filter, removing pollutants and sediments from rainwater runoff, resulting in improved water quality.

- Q: Can geotextiles be used in landfill applications?

- Yes, geotextiles can be used in landfill applications. They are commonly used as part of the liner system in landfills to separate and stabilize different layers of soil and prevent the migration of contaminants. Geotextiles help enhance the overall performance and environmental protection of landfills by promoting proper drainage and reducing the potential for erosion.

Send your message to us

10 Oz High-Performance Monofilament Geotextile Road Building Constructive Felt Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords