High Dimensional accuracy Cold Rolled Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

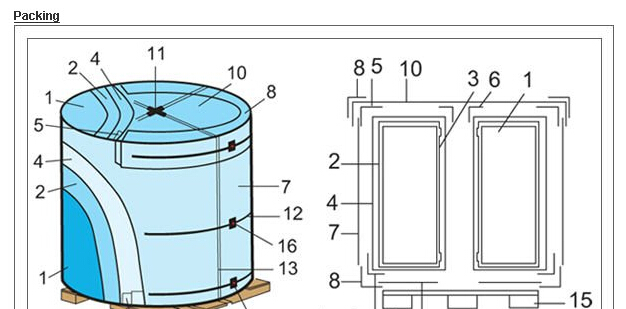

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

St12 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

St13 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

St14 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: What are the different types of steel coil coatings for corrosion resistance?

- Steel coil coatings can be classified into two main types: organic coatings and metallic coatings. 1. Organic coatings are commonly used for steel coil applications due to their excellent corrosion resistance and durability. There are four types of organic coatings: - Polyester coatings: These coatings offer good weatherability and resistance to chemicals, making them suitable for outdoor applications. - PVDF coatings: These coatings are highly resistant to UV radiation, weathering, and chemicals. They provide exceptional durability and are often used in demanding environments such as coastal areas or industrial settings. - Polyurethane coatings: These coatings offer excellent abrasion resistance and a high level of corrosion protection. They are commonly used in applications where there is a higher risk of mechanical damage or exposure to harsh conditions. - Epoxy coatings: These coatings provide excellent adhesion and chemical resistance. They are often used in industrial applications where resistance to chemicals, solvents, and oils is required. 2. Metallic coatings provide effective corrosion protection and can be further divided into two types: - Galvanized coatings: These coatings involve applying a layer of zinc to the steel surface through a hot-dip or electroplating process. This creates a barrier between the steel and the surrounding environment, providing effective corrosion protection. Galvanized coatings are widely used in various industries due to their cost-effectiveness and good durability. - Galvannealed coatings: These coatings are similar to galvanized coatings but undergo an additional heat treatment process. This results in a coating with increased hardness and improved paint adhesion, making it suitable for applications that require additional surface protection or paintability. When selecting the appropriate steel coil coating, it is essential to consider the specific requirements of the application and the level of corrosion resistance needed. Consulting with coating manufacturers or industry experts can help determine the most suitable coating for a particular application.

- Q: i know that steel helmets werent meant to stop bullets, but i was wondering do they have an value whatsoever for stopping bullets, or is that just yet another thing that hollywood made up(like the omaha beach scene in saving private rian)

- They are meant to protect from shrapnel and flying objects,or an enemy's hit to the head. Not meant for protection against bullets [we didn't think so] but at the right angle you could get lucky. What they are useful for is boiling water for coffee etc. Shaving taking a who/e's bath and in the field very handy to have. The bad thing about pots is wearing,you must get accustomed to the weight on your head and neck. You don't think you ever will but finally you do,and because it's many uses and you must wear it,you do!

- Q: I'm a hiker and cook on a camp fire with a canteen cup. So which would be a better material for cooking on a campfire with, aluminum or stainless steel?

- Stainless steel and as to the soot problem, it isn't. Black absorbs heat faster, so if you let the pan get blackened it will heat up better for you. Most people used cast iron for campfire cooking and it was black and worked well. Trouble with cast iron is it weighs and ton and not good for hiking with.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: How are steel coils used in the automotive stamping industry?

- Steel coils are used in the automotive stamping industry to provide a continuous supply of flat steel sheets that are then fed into stamping machines. These coils are unrolled, straightened, and then fed through the stamping presses to create various automotive parts, such as body panels, chassis components, and other structural parts. The use of steel coils ensures efficiency, precision, and a consistent quality in the production of automotive parts.

- Q: Can you suggest me names of sites which aids in construction of Pre Fabricated Steel Buildings.

- just google pre fabricated steel buildings

- Q: How are steel coils used in the production of shipbuilding components?

- Steel coils are used in the production of shipbuilding components as they provide a strong and durable material for constructing various parts of ships such as hulls, decks, and bulkheads. These coils are processed and shaped into required forms, ensuring the structural integrity and stability of the ship.

- Q: What are the advantages of using steel coils?

- There are several advantages of using steel coils. Firstly, steel coils are highly durable and can withstand extreme conditions, making them suitable for various applications. Secondly, they provide excellent strength and stability, making them ideal for structural purposes. Additionally, steel coils can be easily molded into different shapes, allowing for customization and versatility in design. Moreover, steel coils have a high recycling rate, making them an environmentally friendly choice. Finally, steel coils offer cost-effectiveness due to their long lifespan and low maintenance requirements.

- Q: I wanted to know what is steel fabricating?

- Steel Fabricating/or Steel Fabricators is just a fancy way of saying that they sell steel products and a variety of related services. Thomas steel products has a wide range of steel products and services, from Windsor Republic Door Dist, Tie Wire, Steel Doors Frames, Snap Ties, S Parker Hardware Distributor, Reinforcing Steel Detail Drawings Avail, Rebar Fabrication, o_O.

- Q: I downloaded broken steel, the notice of my level cap raising was shown, but after reaching the Jefferson Memorial (when you are supposed to activate the purifier) if I kill Colonel Autumn, then Lyons simply says that we must secure the area, and I can't complete the mission. If I let Autumn live, then she gets stuck in a loop saying Steel be with you over and over. Has anyone else experienced this/how can I fix this? I paid $10 for the expansion and I'm getting ripped off.

- for my area i've got in no way stricken with achievements. Hell, i've got in no way logged into domicile windows stay in six months for the reason that this game got here out. i do no longer even have the disk in my laptop. I merely launch by FOMM and FOSE. you already know what achievements i like, making mods. human beings love a number of my mods, and to me this is a real success. the sport is merely game, enjoying it would not recommend something, this is different from you lived in SE Asia for 6 months in a shack with out working water with a warm distant places female you met on line and then introduced her and your toddler back to stay inclusive of your mom, no, you haven't any longer achieved something different than to be entertained by skill of somebody else's success. Oh, specific you have solved some mysteries, explored some areas and located some issues that have been hidden, yet you likely regarded up on line the places for lots of the stuff you discovered besides. Oh, and to respond to your question: Bethesda's engaged on it, alongside with fixing the a million.5 replace that kills mods with outdoors adjustments by skill of making the sport crash on shop.

Send your message to us

High Dimensional accuracy Cold Rolled Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords