High Alumina Brick for Mining, Metallurgy, and Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is High Alumina Brick?

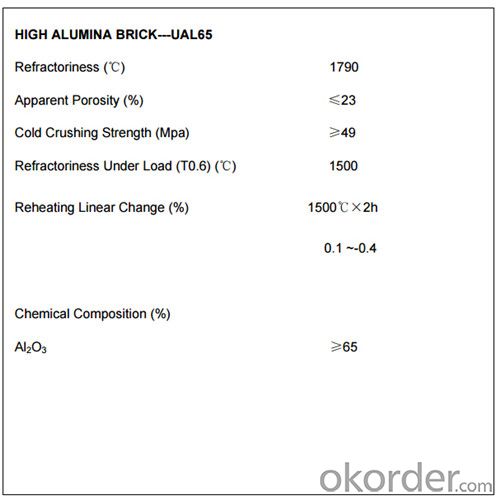

High Alumina Bricks are produced with selected bauxite chamotte as main raw material, fired at 1450-1470 °C by advanced process with strict quality control.

Image of High Alumina Brick

Technical Data of High Alumina Brick

What are the features of High Alumina Brick?

High Alumina bricks have great features like high temperature performance, great corrosion and wear resistance, high bulk density, low iron content, etc. High Alumina bricks are extensively used in mining, metallurgy, cement, chemical and refinery and refractory industries.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: What are the reasons for the spalling of refractory bricks in the production of lime kiln?

- In the course of the production of lime kiln, the local block of refractory brick is a very dangerous signal. It is suggested that you stop the kiln to prevent the collapse of a large area. Lime kiln is the main equipment for the production of limestone kiln and rotary kiln is two, with the growth of calcium carbide lime kiln industry, iron and steel industry, the construction industry to the amount of limestone has become the main production equipment, and refractory bricks became the heart of lime kiln.

- Q: What refractory material does cupola lining use?

- Materials defined as physical and chemical properties that allow them to be used in a high temperature environment are called refractory materials. Refractory materials are widely used in metallurgy, chemical, petroleum, machinery manufacturing, silicate, power and other industrial fields, the largest amount of metallurgical industry, accounting for 50% ~ 60% of the total output.

- Q: What are the requirements for Rubble backfill height?

- Backfill should be filled with large stones, big face, small face upward, the decoration is stable, and then use small stones leveling, the gap between the stones can be swept into the slag, gravel, so that the gap filled.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: Can high alumina brick resist carburizing?

- It is heavy brick mullite brick, brick to do the heavy weight to more than 2.4 manufacturers can achieve a few feeling

- Q: What are the alloy wear resistance materials?

- KNMn19Cr2 (patent) high manganese alloy (ZGMn13Cr2MoRe), super high manganese alloy (ZGMn18Cr2MoRe); two: anti-wear chromium cast iron series: such as high, medium and low chromium alloy cast iron (Cr15MOZCu); three: wear resistant alloy steel series: such as, low and high carbon multi metal combined steel (such as ZG40SiMnCrMO and ZG35Cr2MoNiRe); four: ADI (ADI) series; five: all kinds of composite or gradient material and hard alloy materials, nano KN alloy (patent product): such as chromium carbide composite (Cr2C3+Q235), high-energy ion osmosized tungsten carbide materials (WCSP), high toughness of cemented carbide (YK25.6), KN999 nano alloy (Beijing Naimo patent) etc.;

- Q: The difference between light high alumina brick and heavy aluminum brick

- High aluminum brick is one of the ideal heat insulating material, with high strength, low thermal conductivity, good insulation performance, low price and other characteristics, has been widely used in ceramic tunnel kiln, roller kiln, shuttle kiln, kiln wall, it is also used in various heating furnace coking furnace of iron and steel industry and other thermal equipment heat treatment, lining material, and has broad market prospects.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- High alumina brick clay brick up to 1700 degrees above 1500 degrees -1750 degrees of magnesia brick and magnesia chrome brick 1500-1650 degrees, I is the production of clay brick, brick my temperature at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Forming high alumina brick will be tested on some professional equipment, it is suggested that you can go to the professional testing department to know about it!

- Q: The difference between clay bricks and clay bricks

- Clay brick is a small building with artificial bulk. Also called sintered brick. Solid clay brick is one of the oldest building materials in the world. It is a building material that is loved by the people.

Send your message to us

High Alumina Brick for Mining, Metallurgy, and Cement

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords