High Adhesiveness and Preciseness Prepainted Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Prepainted Steel Sheet1.Common polyester paint

2.50-150g/m2 dipped layer

3.2 Coating 2 Baking process

4.Long life span

Prepainted Steel Sheet

Brief Introduction

1. Prepainted Steel Sheet is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metals for Prepainted Steel Sheet consist of cold rolled, HDG electro-galvanized and hot-dip alu-zinc coated. The finish coats of Prepainted Steel Sheets can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

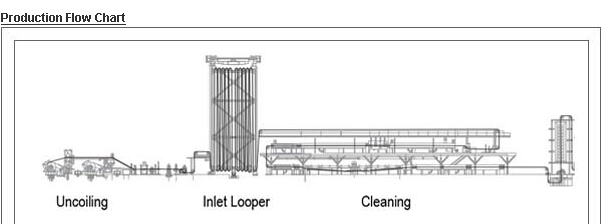

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Prepainted Steel Sheet has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Prepainted Steel Sheets can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

- Q: What are the different types of steel tubes and their uses?

- There are several different types of steel tubes, each with its own specific uses. Some common types include carbon steel tubes, stainless steel tubes, alloy steel tubes, and galvanized steel tubes. Carbon steel tubes are most commonly used for general-purpose applications such as structural support or fluid transportation. Stainless steel tubes are known for their corrosion resistance and are commonly used in industries such as food processing, medical, and chemical. Alloy steel tubes are made from a combination of different metals and are used in high-temperature or high-pressure applications. Galvanized steel tubes have a protective zinc coating and are often used in outdoor or corrosive environments.

- Q: What are the uses of steel in the oil and gas industry?

- Steel is widely used in the oil and gas industry for various applications due to its strength, durability, and resistance to corrosion. It is commonly used in the construction of oil rigs, pipelines, and storage tanks. Steel is also used in the manufacturing of valves, fittings, and other equipment necessary for the extraction, refining, and transportation of oil and gas. Its exceptional properties make steel a reliable and essential material in ensuring the safety and efficiency of operations in the oil and gas industry.

- Q: How does steel plate rolling work?

- Steel plate rolling is a metal fabrication process that involves passing a flat sheet or plate of steel through a set of rollers to progressively bend and shape it into a desired form or curvature. The rollers apply force to the steel, reducing its thickness and elongating its length as it passes through. This process is commonly used to produce cylinders, cones, and other curved shapes for various applications in industries such as construction, manufacturing, and transportation.

- Q: What are the different types of steel tanks and containers available?

- There are several types of steel tanks and containers available, including above-ground storage tanks, underground storage tanks, pressure vessels, intermediate bulk containers (IBCs), and shipping containers. Each type serves a specific purpose and is designed to meet different storage or transportation needs.

- Q: What are the advantages of using steel in the manufacturing of security doors and windows?

- The advantages of using steel in the manufacturing of security doors and windows include its high strength, durability, and resistance to forced entry. Steel is a robust material that can withstand harsh weather conditions and physical attacks, offering enhanced protection against burglaries and break-ins. Additionally, steel doors and windows provide excellent fire resistance properties, making them a reliable choice for ensuring the safety and security of homes and commercial buildings.

- Q: What are the different types of steel coils and their applications?

- There are several types of steel coils used for various applications. Hot rolled steel coils are commonly used in construction, automotive, and manufacturing industries due to their strength and versatility. Cold rolled steel coils are ideal for precision engineering, appliances, and electrical components as they offer a smooth finish and enhanced dimensional accuracy. Galvanized steel coils are coated with zinc to prevent corrosion and are commonly used in roofing, fencing, and automotive parts. Stainless steel coils are known for their resistance to corrosion and heat, making them suitable for applications in the food processing, medical, and chemical industries.

- Q: How is steel used in the construction of sports facilities?

- Steel is used in the construction of sports facilities for various purposes, such as the framework for stadiums, arenas, and indoor sports complexes. It provides structural support, allowing for large open spaces and the ability to accommodate thousands of spectators. Steel is also used in the construction of roofs and canopies, providing durability and resistance to harsh weather conditions. Additionally, steel is utilized in the fabrication of seating, stairs, and other architectural elements, ensuring safety and functionality in sports facilities.

- Q: What are the applications of steel gratings in oil refineries?

- Steel gratings have various applications in oil refineries. They are commonly used for platforms, walkways, and stair treads, providing a safe and durable surface for workers to navigate the facility. Steel gratings also serve as air ventilation grilles, allowing for proper airflow and preventing the accumulation of hazardous gases. Additionally, they are utilized in trench covers, ensuring the safety of personnel and equipment by covering open trenches and channels. Overall, steel gratings play a crucial role in oil refineries by enhancing safety, providing structural support, and facilitating efficient operations.

- Q: How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities due to their strength, durability, and versatility. Steel is commonly used for framing structures, providing a strong and stable framework for the building. Additionally, steel is used in the fabrication of laboratory equipment, such as benches, cabinets, and storage units, ensuring the durability required for scientific experiments and research activities. Furthermore, steel is resistant to fire, corrosion, and pest infestation, making it a reliable choice for long-term use in these specialized facilities. Overall, steel products contribute to the construction of research laboratories and scientific facilities by providing the necessary structural support and ensuring the durability and safety of the building and its equipment.

- Q: What are the common types of steel products used in the pet grooming and care industry?

- Some common types of steel products used in the pet grooming and care industry include grooming scissors, blades, combs, brushes, nail clippers, and grooming tables. These products are often made from stainless steel, which is durable, rust-resistant, and easy to clean, making it ideal for the grooming and care of pets.

Send your message to us

High Adhesiveness and Preciseness Prepainted Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords