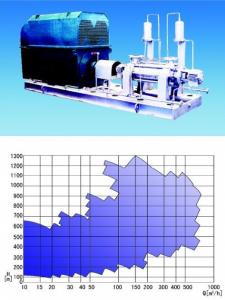

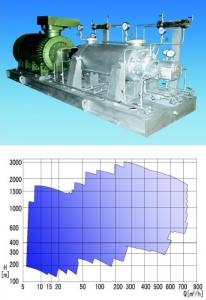

HGB,Horizontal, radially split, multistage ring-section pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Design |

Overview of technical data

| Type of installation | Long- coupled |

| Maximum drive rating | 5. 000 kW |

| Type of bearing | Rolling element and plain bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 7. 000 1/min |

| Maximum flow rate | 1. 650 m³/h |

| Maximum discharge-side pressure | 200 bar |

| No. of impeller entries | Single / Double entry |

| Casing material | Carbon steel |

| Minimum flow rate | 15 m³/h |

| Suction characteristics | Non- priming |

| Drive voltage | Low voltage, high voltage |

| eClass assignment | 36410100; 36410000;36410101 |

| Other impeller types | Closed / Radial |

| Pump set location | Dry installed |

| Type of suction casing | Annular casing |

| Max. permissible fluid temperature | 200 °C |

| Type of discharge casing | Annular casing |

| Type of first impeller | Single entry / Double entry |

| Main applications | Industry and process engineering; Energy |

| Type of installation | Stationary |

| Type of connection | Flange, loose flange |

| Type of lubrication | ( forced) oil lubrication |

| Type of drive | Electric motor, turbine |

| Installation position | Horizontal |

| Maximum suction pressure | 30 bar |

| Type of coupling | Geared variable speed coupling; Gear;Variable speed coupling;Direct |

| Shaft seal type | Mechanical seal; Gland packing |

| Maximum head | 2. 000,00 m |

| Maximum rated pressure (discharge) | PN 63, PN 100, PN 160, PN 250 |

| Minimum head | 300, 00 m |

| Type of stage casing | Stage casing with diffuser |

| Nozzle position | Variable |

| Casing partition | Radially split |

- Q: heavy machinery like a bulldozer - construction equipment

- A license to kill.

- Q: BOOK OF PAGESBook of prophet Fronkey 11:33:44:56:789aAnd he say 'choot em' and he use the machinez with the pipes to take away aur soulz. And in heaven VegetableSkinMan say 'criae criae cryai' and then they try more sacrifice to great Marshmelo in field of treez. and will of Great Pumpkin is done..

- You can not take away what is not there. I have no soul. You have no soul. Nobody does.

- Q: eg cranes,excavators,backhoes.....bulldozers.....except hydraulic brakes.....URGENT

- ball joints on the cylinder

- Q: What are deck machineries?

- Assuming that your question refers to ships rather than boats: The deck mounted mechanical equipment such as mooring and anchor winches, cargo and stores cranes and hatch hydraulics. PS the correct expression is deck machinery (already plural )

- Q: What do you do during shore duty?Which one would you say has the best outlook for an 20+ year career?Are these the hardest working jobs on the boat?

- I have served with each of these. Shore duty tends to be in factories alongside a pier. They are called: Intermediate Maintenance and Repair Facilities. Basically machine shops that rebuild valves. However I know one guy that was on a boat with me who got orders to NAS Fallon Nevada to be in charge of their go-cart course. They needed a EN to keep the go-carts running. The needs of the Navy change every month. To say which rate with advance the fastest is a guess. It changes all the time. If you stay out of trouble, you can serve for 20 years and get a pension. Anyone who guarantees you that by doing 'X' will make you a chief, is lying. They all work hard. And they are each highly valued jobs, with good job prospects when you get out. I would recommend that you consider subs too. The extra pay does not hurt.

- Q: in the indian mutiny what machinery was used in the war to fight?

- The idea that the Great Mutiny was a war of liberation is bullocks. There was no national movement in those days. India didn't exit. India was a continent with semi independent states on it. None wanted to serve under the other. It was much more than a mutiny, but that was simply because it was a religious conflict, in which both Hindus and Muslims fought together. You have to be REALLY incompetent to get that done, but the British managed it! The religious problem was the introduction of a new bullet. It was greased with a mixture of cow's fat and pig's fat. The cartridge had to be bitten open by the user. Very nicely infuriating both muslims and Hindus. -- this is sarcasm, for sensible toes

- Q: What are the advantages of construction machinery?

- In terms of machinery, but compared to machinery, mechanical engineering is more advanced

- Q: can the cost of delivering a piece of machinery be assessed as part of a property's value?

- No. It is a business expense, and does not increase the value of the machine... Best wishes

- Q: I'm interested in investing in candle lantern manufacturing because of low competition in my local area but I'm not sure where to start and what equipment would be needed to start manufacturing on low scale. Is there any good read on how are lanterns recycled and what additional equipment would be needed to recycle them? Please go into as much details as possible.

- From my understanding, most of these candle lanterns are hand- made.

- Q: Bridgeport Series II CNC serial 116model /BO4-02 69-82048-563Bridgeport Series I serial 1-18-0173 model F-7346-01-205Famcoserial PBG-D65VU59model 16-3060Powermaticserial 67-930model 600Dennison Hydroilic MultipressDoAllWiedemann Turret Punch Pressserial 398type R4PWhitney-Jensen Punch Shearsserial 3031160model 150Wiedemann Turret Punch Pressserial 1370type RA41-PPunch ToolingHarrison AA Lathe1021394Hardinge Lathemodel DSM59Di-arco (hydra power press brake)serial 6801074107model 14-48-1Downdraft StationKaeser Compressorserial 1032model AirCenter SX5part 100898.1Grinding WheelTumblerLincoln Arc Welder (Idealarc)serial AC-399591model Tig-300/300code 7723-CBrown Sharpe No. 2Lserial 523-2-1577Ruemelin (Sand Blaster)type 3932-G# 365601'' Belt SanderDrill Press

- I okorder / Some of your equipment will still have documentation from the manufacturer's website ( with model, serial, and other ID numbers)

Send your message to us

HGB,Horizontal, radially split, multistage ring-section pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords